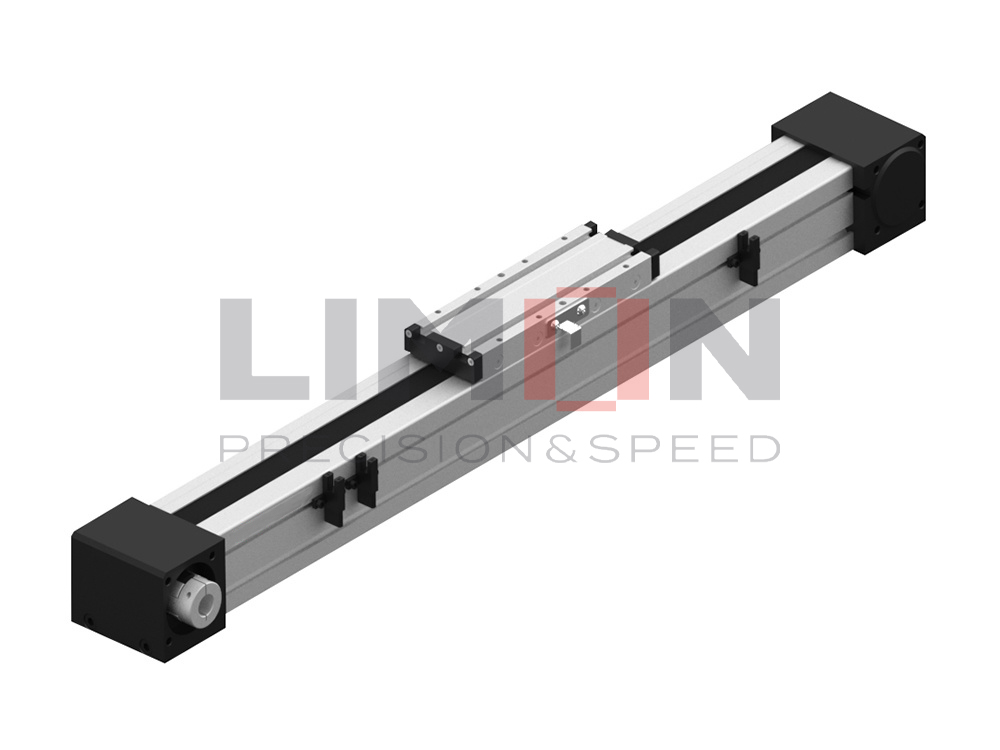

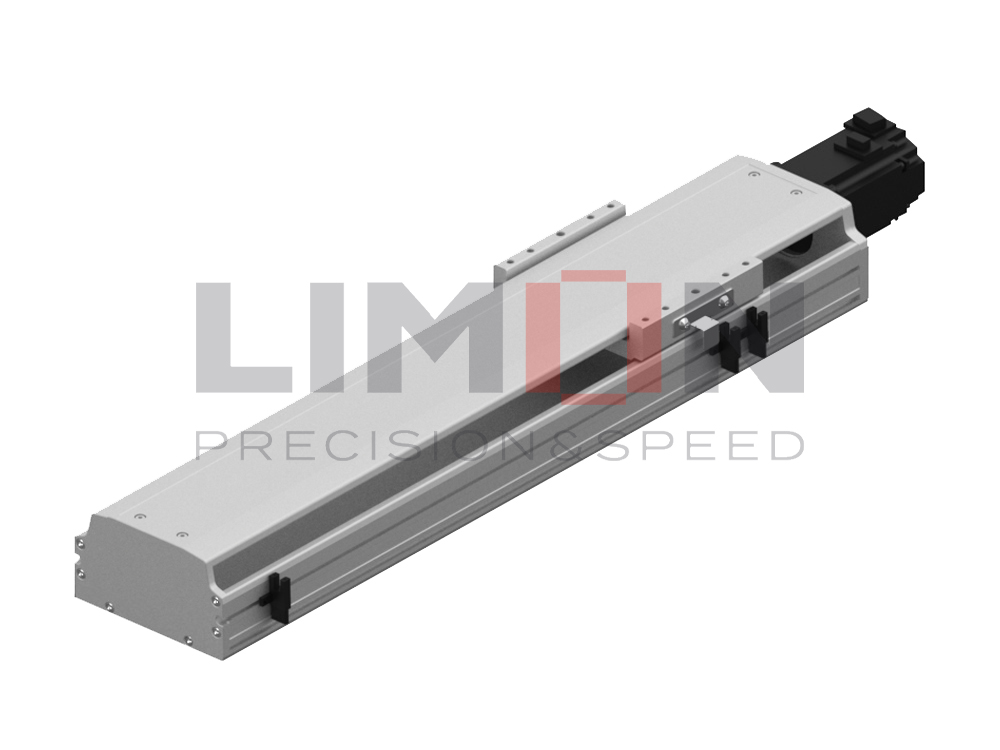

Why Use Belt-Driven Linear Actuators?

Belt-driven linear actuators provide high-speed operation, long travel lengths, and low maintenance requirements, making them ideal for automation applications that require rapid movement and smooth operation. They are lightweight, energy-efficient, and capable of handling high acceleration and deceleration rates while maintaining precision and reliability.

What is a Belt-Driven Linear Actuator Used For?

Belt-driven linear actuators are widely used in various industries, including packaging, automotive, and electronics manufacturing. They are commonly integrated into conveyor systems, pick-and-place machinery, and positioning applications where fast and continuous motion is required. Due to their long travel capabilities and high-speed performance, they are also used in CNC machining, printing, and semiconductor processing equipment.

Why LIMON Belt-Driven Linear Actuators?

LIMON’s belt-driven linear actuators are designed with industry-leading quality and performance in mind. With advanced manufacturing processes and rigorous quality control, LIMON provides actuators that offer:

- High-Speed Performance:Capable of achieving rapid acceleration and deceleration with minimal noise.

- Long Travel Lengths:Suitable for extended linear motion applications without compromising efficiency, we used to offer 12 meters solution to LIMON partner.

- Robust and Durable Design:Engineered for industrial applications, ensuring longevity and reliability.

- Customizable Solutions:LIMON offers tailored actuator designs to meet specific application requirements, gantry system is available.

- Energy Efficiency:Reduced power consumption compared to traditional linear motion systems.

By choosing LIMON’s belt-driven linear actuators, industries can achieve optimal performance in automation and motion control applications.

Belt-driven linear actuators are ideal for high-speed and long-travel applications, providing efficiency, reliability, and cost-effectiveness in industrial automation.