Overview:

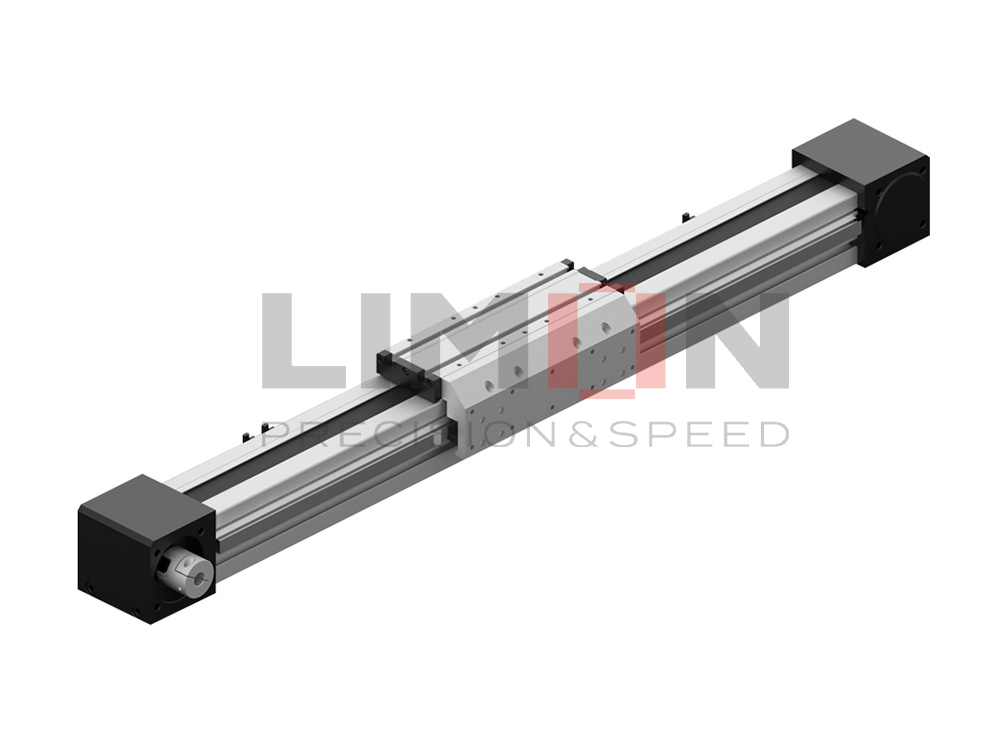

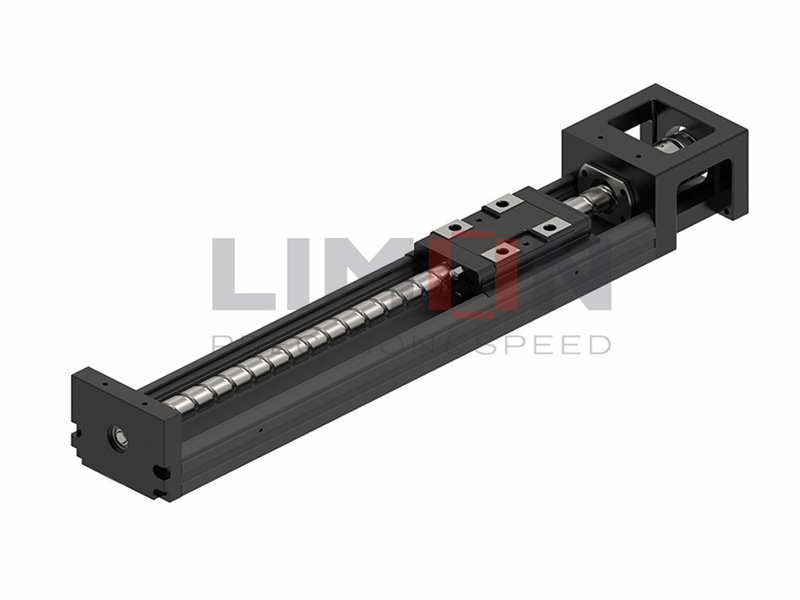

HTO series modules are belt-driven linear actuators, designed based on the preferences of the European market, featuring a square profile design, specifically designed for applications with significant lateral eccentricity.

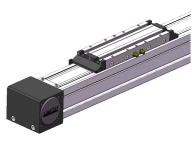

HTZ series modules are belt-driven linear actuators, designed based on the preferences of the European market, featuring a square profile design, specifically designed for applications with significant lateral eccentricity and for Z axis use.

Basic info:

Drive Type: Belt driven type, open type

Stroke:

HTO series: 4000mm (standard), I80/100 can be joint to a longer stroke. (Unlimited)

HTZ series: max 1500mm

Characteristics:

Higher torsional stiffness

- An additional guide rail is placed to the side of the profile, which is connected to the main carriage by a aluminum plate, significantly enhances the overall torsional resistance of the module, suitable for unsupporting applications

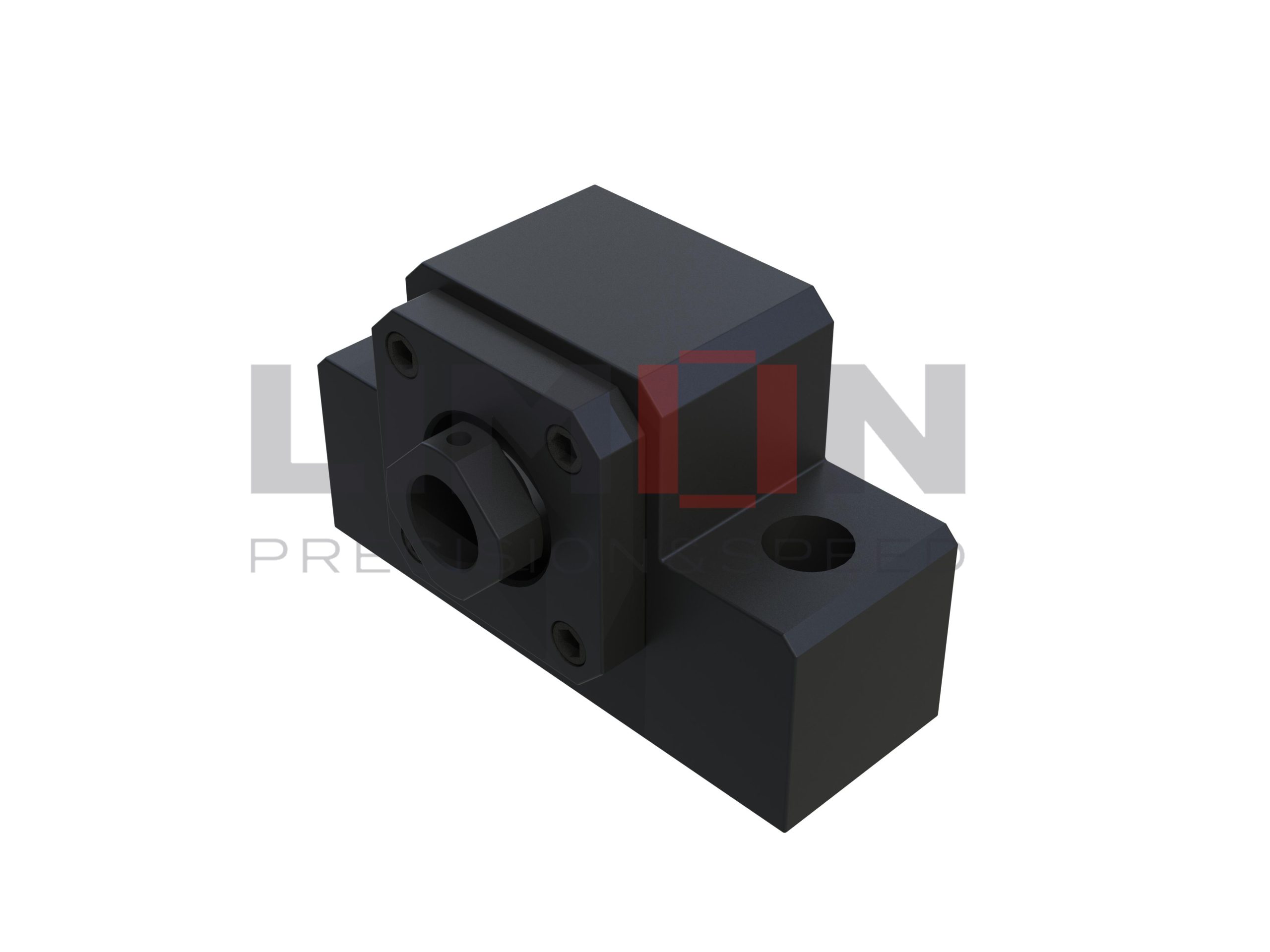

Flexible Motor Collocation

- The integrated structure for pulley and coupling could enhance concentricity and prevents slippage, reduce the motor’s transverse installation length to save space on the machine.

- Reduce the motor’s transverse installation length to save space on the machine.

- The motor mount can be put on the module in any direction and changed according to customer’s different requirement.

Splicable Profile

- For a larger range of application possibilities, profles can be spliced up to 12 meters in length.

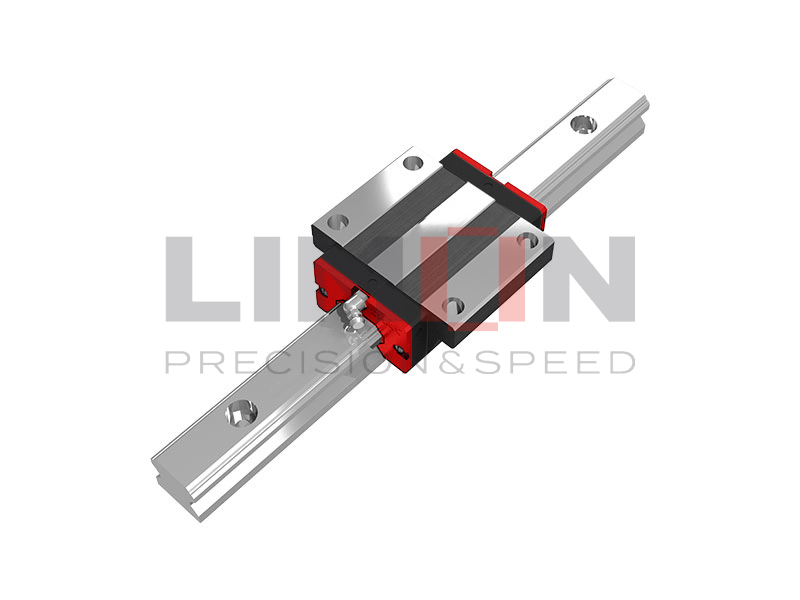

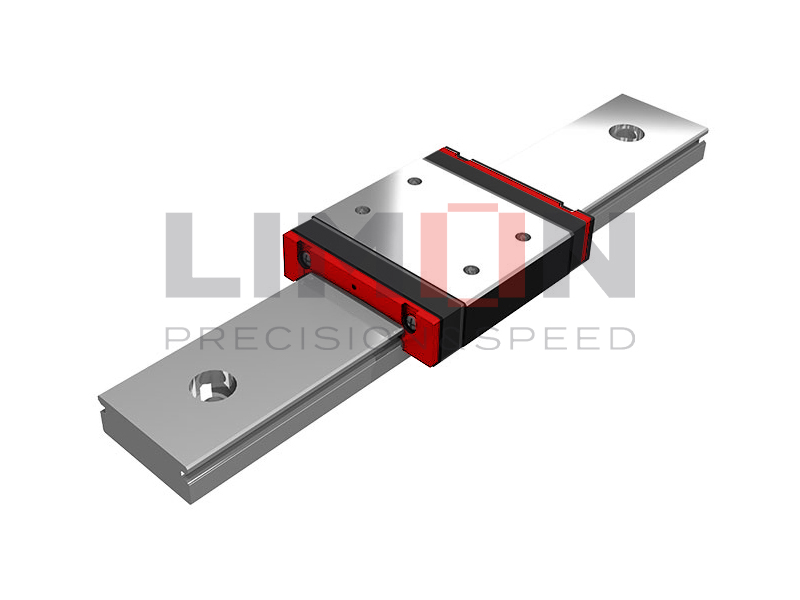

Integrated Oil Injection Hole

- By using an external integrated oil injection hole design,all linear blocks can be lubricated at once without the need for disassembly maintenance.

Profile with Bracket Design

- Impossible of being pressed down,the timing belt creates an enclosed zone inside that effectively inhibits foreign objects from entering.

- When used for long strokes, the timing belt does not sag, preventing friction with the internal structure.

- Stop the timingbelt from fluctuiting and lessen the loudness.

HTZ series use Ω Type Timing Belt

- The timing belt has a type design that makes it especially ideal for quick, long-distance grabbing and handling because the motor and reducer donot move with the unit body.

Industry:

- Automated Production Line – Automotive assembly, electronics manufacturing, home appliance production

- Electronics & Semiconductor – Chip packaging, SMT placement, LCD inspection

- Packaging & Logistics – Food packaging, parcel sorting, warehouse automation

- Medical Equipment – Diagnostic instruments, testing devices, surgical robots

- Printing & Advertising – Large-format printing, laser engraving, digital printing

- Research & Laboratory – Lab instruments, sample testing, biotechnology

- Food & Beverage – Filling machines, labeling machines, packaging lines

- New Energy Industry – Lithium battery production, solar panel assembly