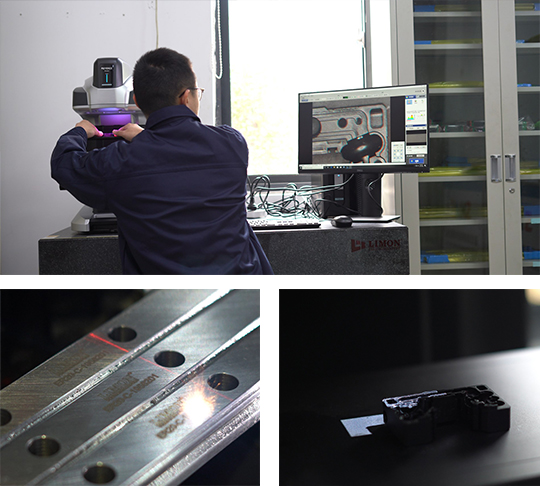

From 2003, LIMON started business by providing LINEAR BUSHINGS to the market. As a leading manufacturer in China, LIMON linear bushing are of great quality, produced in our unique automatic workshop which is the first and only one in China. The size of our products widely range from diameter 4 up to 100mm, with various design versions. We also provide available options for diverse cage, surface coating and different material (carbon steel or stainless steel as option).

After years of development, we have owned a very good image and reputation in both domestic and overseas market. Until now, LIMON has more than 20 years experience in the linear bearing manufacturing industry.