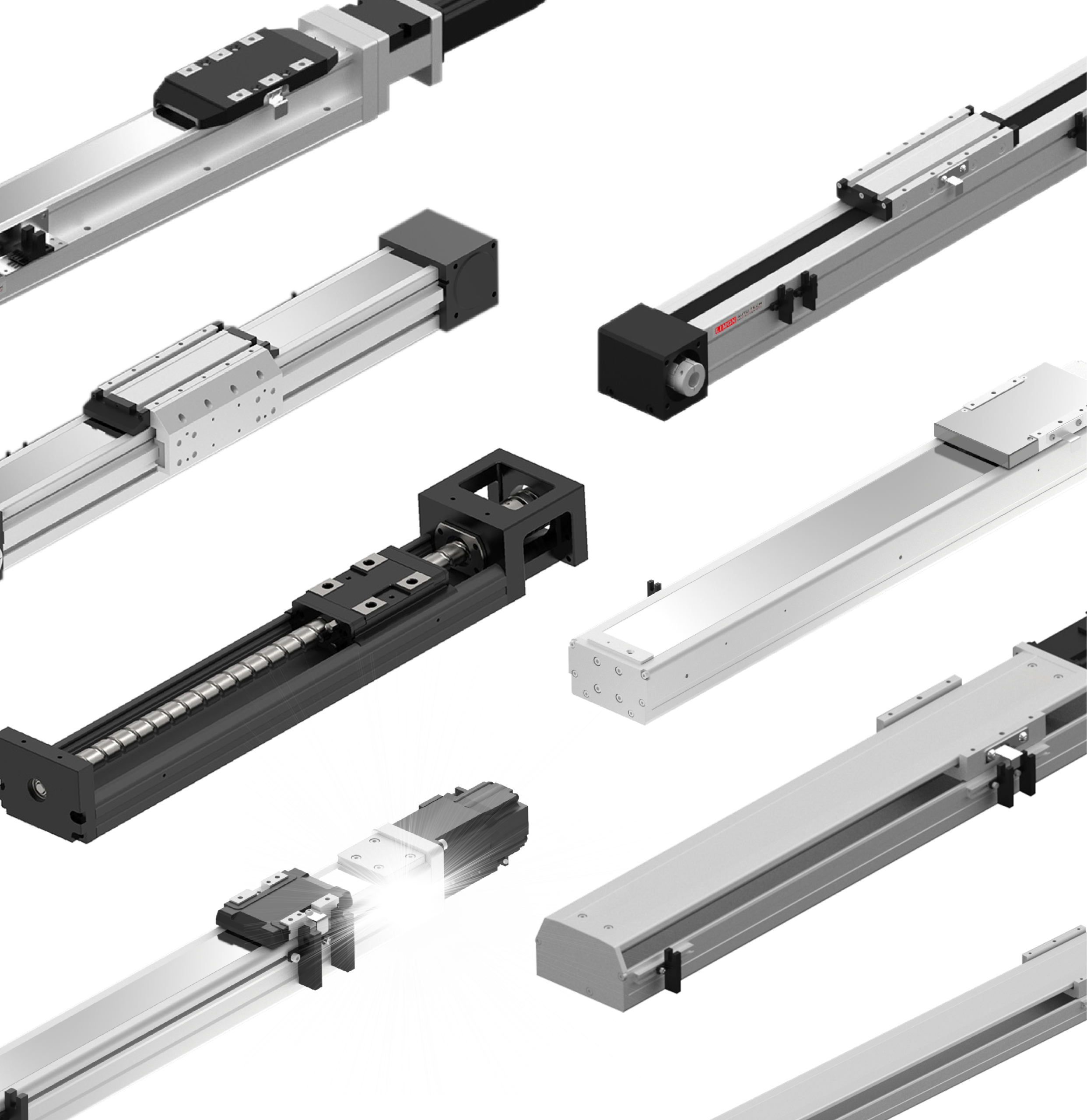

In 2003, LIMON began exporting LINEAR BEARINGS, mainly for OEM production for Japanese customers. As demand grew, we accumulated rich experience. In 2007, LIMON started manufacturing LINEAR GUIDES and BALL SCREWS. To date, we have a very complete product range that can meet the needs of different industries.

With the expansion of the market, LIMON established a Taiwan team in 2012 to develop LINEAR AXES and set up its first base. The following year, we opened our second factory in Ningbo, which is also in the location of LIMON’s headquarters. By 2015, we had gradually expanded both domestic and international markets.

Adhering to the concept of innovation leadership, LIMON has delved deeply into the underlying technologies of automation. By gathering top talents in the intelligent equipment industry, we continuously innovate independently, providing global customers with a series of linear axis products and MULTI-AXIS complex solutions. Currently, LIMON is still following market demands to develop more high-precision new products, such as LINEAR MOTORS and ELECTRICAL PRODUCTS, aiming to offer customers more comprehensive solutions! Today, our products have been sold to 39 countries in Europe, Asia, South America, and North America.

For the past two decades, LIMON has been dedicated to the field of intelligent manufacturing. We are committed to providing system solutions for industrial automation and promoting the upgrading of China’s industry.

In the future, LIMON will continue to uphold an efficient and pragmatic attitude, offering customers more practical solutions, higher-quality products, and more professional services.