What are the reasons to use a ball screw linear actuator?

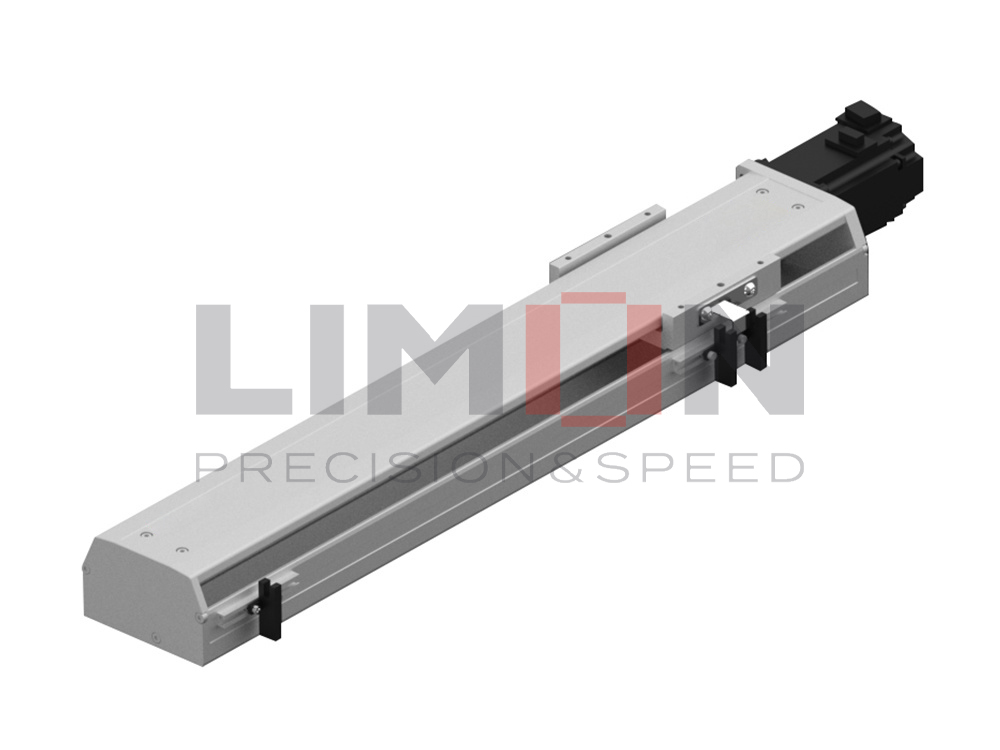

A ball screw linear actuator offers high precision, efficiency, and load capacity, making it ideal for automation and industrial applications. Its screw-driven design ensures minimal friction, high repeatability, and smooth operation. Unlike belt-driven systems, it provides superior rigidity and longevity, making it a reliable choice for linear units requiring precise movement.

What are the features of a ball screw linear actuator?

Ball screw linear actuators provide high precision, low friction, and exceptional efficiency. Their screw-driven mechanism ensures smooth motion with minimal backlash, making them ideal for demanding industrial applications. Additionally, they offer excellent load-bearing capacity and durability, contributing to long service life and reliability.

High Precision and Accuracy

The ball screw mechanism reduces backlash and ensures high positioning accuracy, making it suitable for CNC machines, semiconductor equipment, and other precision-driven applications.

Efficiency and Low Friction

Compared to conventional lead screws, ball screw linear actuators feature rolling ball bearings that significantly reduce friction, leading to higher efficiency and lower energy consumption.

High Load-Bearing Capacity

Designed for heavy-duty applications, ball screw linear actuators support greater loads compared to belt-driven systems, making them ideal for industrial automation and machining processes.

Smooth and Consistent Motion

The rolling motion of the ball bearings provides a smoother linear motion with minimal noise and vibration, ensuring stable performance in high-speed applications.

Extended Service Life

With proper lubrication and maintenance, ball screw actuators have a longer operational lifespan than lead screws, reducing downtime and maintenance costs.

Superior Rigidity and Stability

The screw-driven design enhances structural rigidity, minimizing deflection under load and ensuring precise movement over long distances.

What is the application of ball screw linear actuator?

Ball screw linear actuators are widely used in various industries due to their high precision, efficiency, and durability. Below are some key applications:

Ball screw linear actuators are widely used across various industries, including:

- CNC machining– For high-precision positioning in milling, drilling, and cutting operations.

- Automation systems– Ensuring precise motion control in robotic arms, assembly lines, and pick-and-place applications.

- Medical equipment– Used in diagnostic machines and precision-controlled surgical instruments.

- Semiconductor manufacturing– Providing stable and accurate movement in microelectronics production.

- Aerospace and automotive industries– Supporting testing and prototyping applications requiring high-accuracy motion.

By leveraging the benefits of a ball screw linear actuator, industries can achieve superior precision, efficiency, and durability in their motion control systems, ensuring long-term operational success.

Summary

Ball screw linear actuators provide high precision, smooth motion, and durability across various industries. Their applications range from CNC machining and semiconductor production to medical equipment and aerospace systems. With their efficiency and reliability, ball screw linear units continue to be a vital component in industrial automation and precision engineering.