Choosing the wrong motor creates inefficiency, overheating, and performance issues. Poor choices damage equipment and increase costs. The solution is understanding stepper vs. DC motor differences.

Stepper motors move in precise increments controlled by input pulses, while DC motors rotate continuously with varying voltage. Understanding their differences ensures correct application, efficiency, and durability.

Keep reading to explore their definitions, characteristics, and critical differences.

What Is A Stepper Motor?

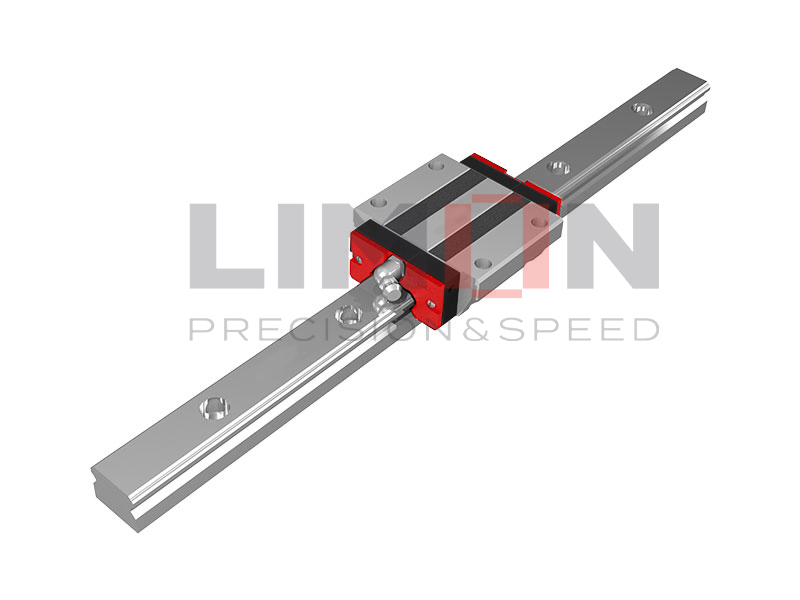

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. Unlike continuous-rotation motors, stepper motors rotate in fixed angular steps. Each pulse applied to the motor corresponds to a step in its rotation, making it highly accurate for positioning tasks.

Stepper motors are widely used in industries requiring precision control, such as robotics, CNC machines, medical equipment, and 3D printers. They can operate without feedback systems (open-loop control), simplifying design and lowering costs.

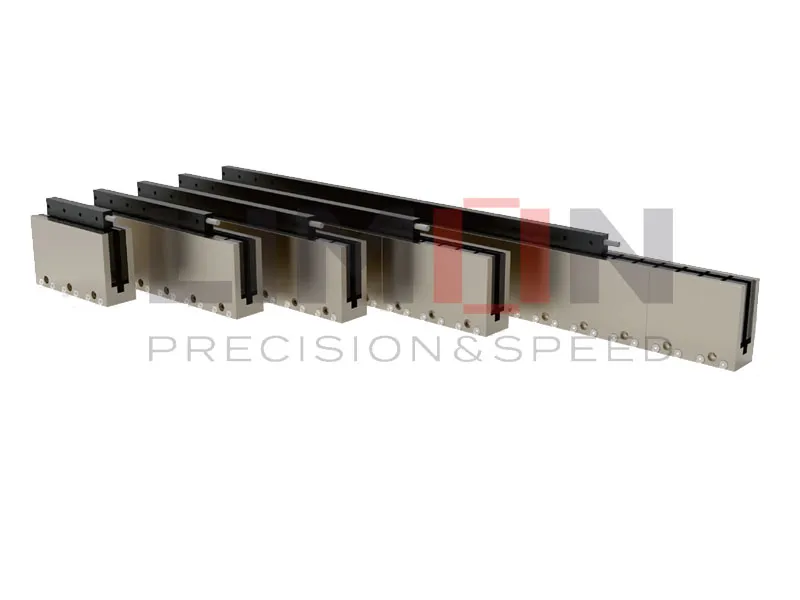

The main types of stepper motors include:

Permanent Magnet Stepper Motor (PM): Offers simple construction and good low-speed torque.

Variable Reluctance Stepper Motor (VR): Lightweight, affordable, but with limited torque.

Hybrid Stepper Motor: Combines the best features of PM and VR, providing higher accuracy and torque.

While stepper motors are reliable and precise, they have limitations. At high speeds, torque drops significantly, and without closed-loop feedback, they can lose steps under heavy loads. Despite these drawbacks, their accuracy, simplicity, and cost-effectiveness make them a preferred choice in precision-driven applications.

What Is A DC Motor?

A DC motor is a rotary electrical machine that converts direct current (DC) electrical energy into mechanical energy. Unlike stepper motors, DC motors rotate continuously when voltage is applied, with speed proportional to the supply voltage and torque influenced by current.

There are different types of DC motors:

Brushed DC Motor: Uses brushes and a commutator to deliver current. Simple and affordable, but requires regular maintenance due to brush wear.

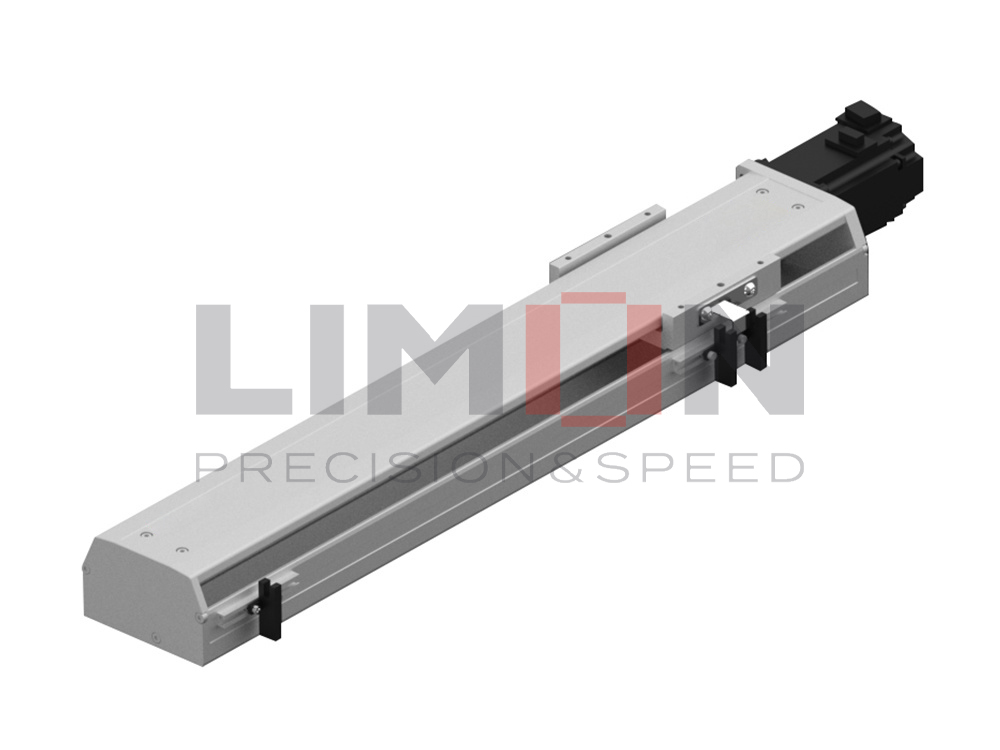

Brushless DC Motor (BLDC): Uses electronic commutation, offering higher efficiency, longer life, and less maintenance. Widely used in electric vehicles, drones, and automation.

DC motors are popular for applications requiring constant speed, smooth rotation, and high efficiency. They are commonly found in automotive systems, fans, pumps, and conveyor belts.

While DC motors provide excellent continuous motion, they typically require feedback or controllers for precise positioning tasks, which stepper motors can achieve more naturally.

Difference Between Stepper Motor And DC Motor

The primary distinction between stepper motors and DC motors lies in their control mechanism, precision, and application focus.

Motion Control:

Stepper motors move in discrete steps, making them ideal for accurate positioning. DC motors, on the other hand, provide smooth, continuous rotation.Control Requirements:

Stepper motors are controlled by pulses, requiring a driver to sequence steps. DC motors operate by simply adjusting the voltage.Accuracy and Feedback:

Stepper motors can achieve precise motion without feedback (open-loop), while DC motors typically need encoders for exact positioning.Torque Characteristics:

Stepper motors deliver high torque at low speeds but lose torque at higher speeds. DC motors generally maintain torque better across a wider speed range.Applications:

Stepper motors are used in precision-driven industries (CNC, robotics, 3D printing). DC motors are preferred in applications requiring continuous rotation and efficiency (fans, pumps, vehicles).

Comparison Table: Stepper Motor vs DC Motor

| Feature | Stepper Motor | DC Motor |

|---|---|---|

| Motion | Moves in discrete steps | Continuous smooth rotation |

| Control | Pulse-driven, requires driver | Voltage control, simple operation |

| Accuracy | High, no feedback required (open-loop) | Requires encoders for precision |

| Torque | High torque at low speeds, drops at high speeds | Consistent torque across speed range |

| Maintenance | Brushless, low maintenance | Brushed motors require frequent maintenance |

| Applications | CNC, robotics, medical devices, 3D printing | Fans, pumps, EVs, conveyor belts |

This comparison highlights how stepper motors excel in precision control, while DC motors are best suited for continuous motion and efficiency.

Conclusion

Stepper motors deliver precision; DC motors provide continuous power. Choosing wisely ensures optimal performance, efficiency, and application success.For further questions please contact [email protected]