In the world of industrial automation and mechanical design, choosing the right type of bushing is crucial for performance, reliability, and maintenance strategy. Whether you’re building a CNC machine or optimizing equipment for how to fulfill dropshipping orders on Shopify, understanding the differences between linear bushings and oil-free bushings will steer you toward smarter decisions.

1. Lubrication Requirements

Linear Bushing

-

Requires external lubrication (oil or grease).

-

Essential for reducing friction and extending lifespan.

-

Ideal for high-speed, precision-based applications like robotics and factory automation.

Oil-Free Bushing

-

Self-lubricating: made with embedded solid lubricants like graphite or PTFE.

-

No need for external lubrication — a major plus in environments where maintenance is a challenge.

-

Especially useful in packaging lines, food-grade machinery, or environments involving dust and debris.

2. Structure & Material Composition

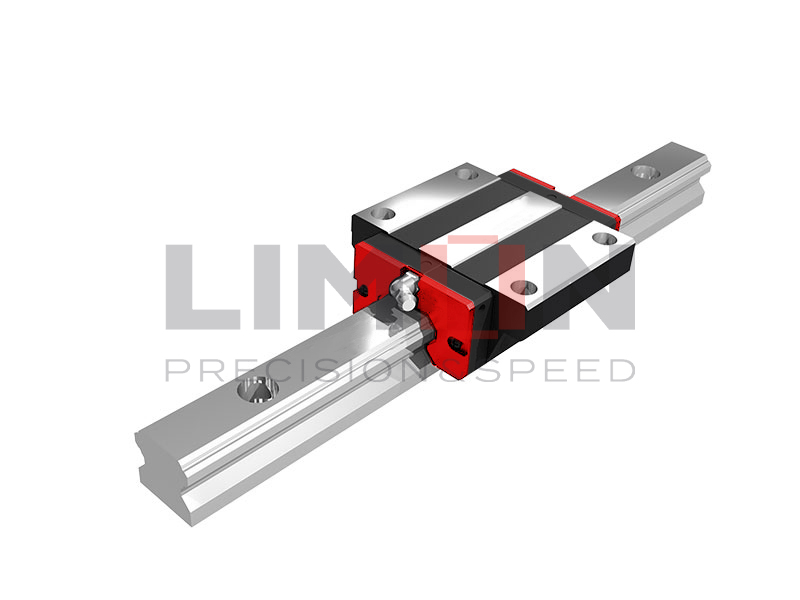

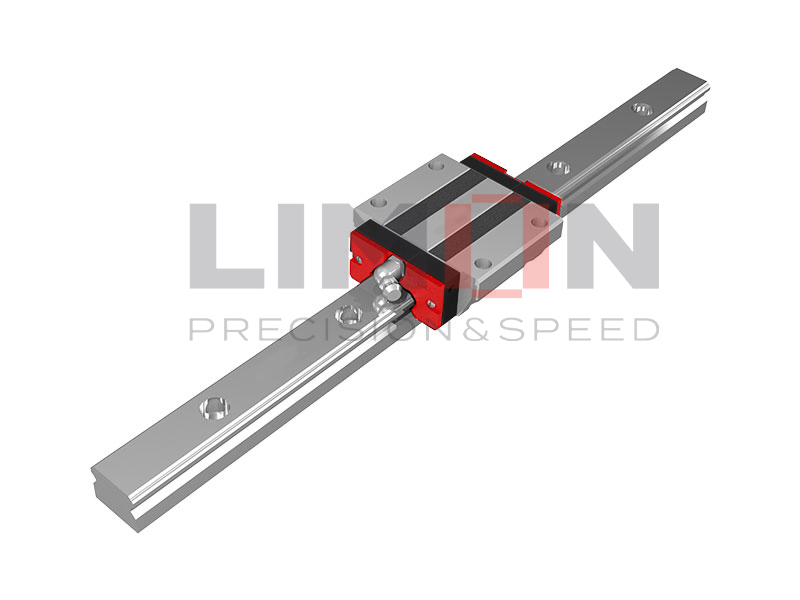

Linear Bushing Construction

-

Made of steel or engineered plastic housings.

-

Contains multiple recirculating ball bearings for ultra-smooth linear motion along a shaft.

-

Designed for applications requiring high precision and low friction.

Oil-Free Bushing Construction

-

Built from sintered bronze, composites, or engineered polymers.

-

Internal solid lubricants eliminate the need for routine oiling.

-

Offers quiet operation and long life, even under challenging conditions.

3. Applications & Ideal Use Cases

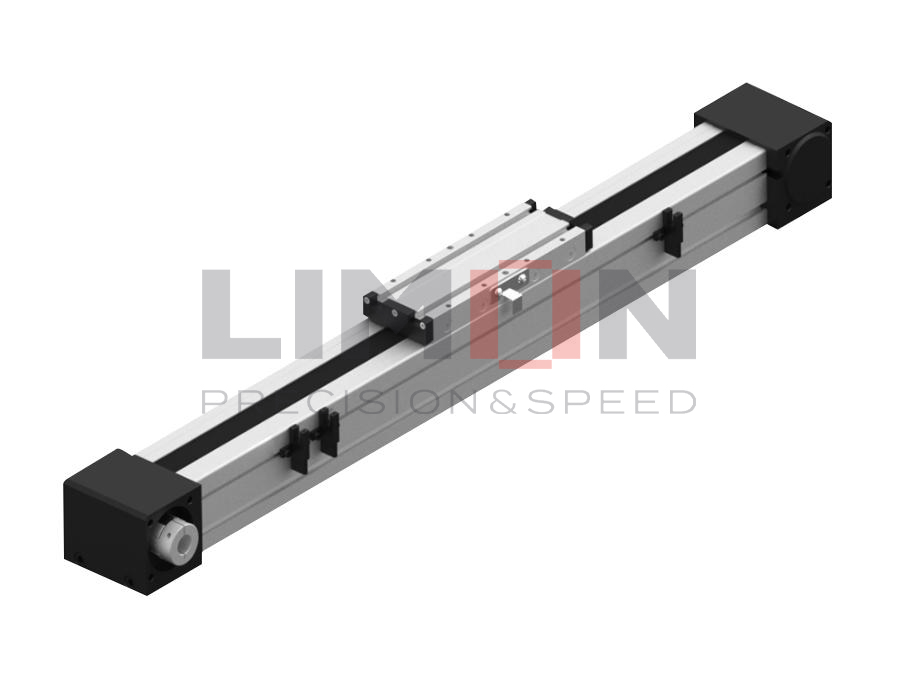

Where Linear Bushings Shine

-

CNC machinery

-

3D printers

-

Medical automation

-

Robotics

-

Assembly lines that require high-speed linear motion

These are also common in modern e-commerce fulfillment systems — particularly in automated solutions for how to fulfill dropshipping orders on Shopify, where precision and repeatability matter.

Where Oil-Free Bushings Win

-

Food & beverage equipment

-

Cleanrooms

-

Outdoor or dusty environments

-

High-temperature systems

-

Areas with restricted access for maintenance

They’re a favorite in “set-and-forget” machinery that just needs to run — no lube, no fuss.

4. Maintenance Requirements

Linear Bushings

-

Require regular maintenance and periodic relubrication.

-

Can deliver top performance but demand attention over time.

Oil-Free Bushings

-

Zero maintenance.

-

Perfect for companies that value uptime over tinkering.

-

Fewer moving parts, fewer headaches.

Materials Used in Linear Bushings

Choosing the right material isn’t just about durability — it’s about aligning with your application, budget, and environmental constraints.

Bearing Steel (e.g., SUJ2, 52100 Steel)

-

Excellent wear resistance

-

Ideal for high-load, high-speed operations

-

Requires lubrication

Stainless Steel (e.g., SUS440C, SUS304)

-

Corrosion-resistant

-

Perfect for cleanrooms, medical, or food-grade environments

Bronze (e.g., Sintered Bronze, Phosphor Bronze)

-

Common in oil-free bushing designs

-

Infused with solid lubricants for self-lubricating properties

Engineering Plastics (PTFE, POM, PA, UHMW-PE)

-

Lightweight, chemical-resistant, and maintenance-free

-

Great for applications with limited load or in corrosive conditions

Composite Materials (PTFE-coated metals, fiber-reinforced polymers)

-

Combine the strength of metals with the low friction of polymers

-

Long service life and ideal for harsh or high-load applications

Final Takeaway

The right bushing for your project depends on what you value most — precision, maintenance-free performance, or resilience in extreme environments.

-

Choose linear bushings when precision linear motion and high-speed operation are your top priorities.

-

Choose oil-free bushings when maintenance-free performance in harsh or sensitive environments is critical.