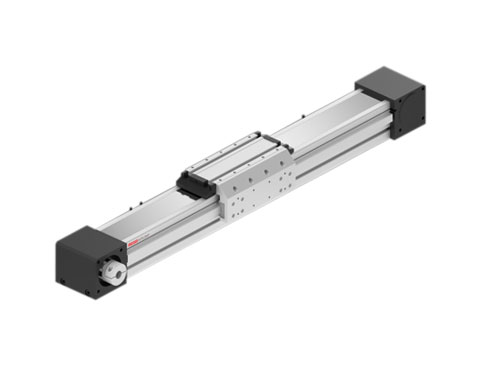

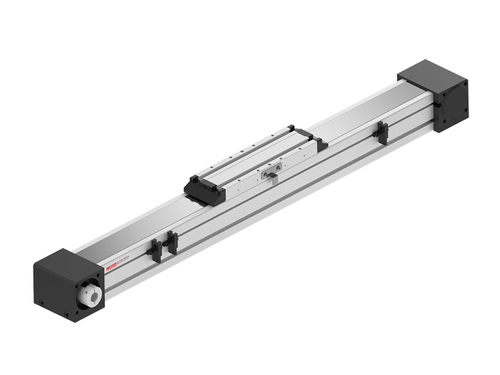

Belt Driven Linear Actuator

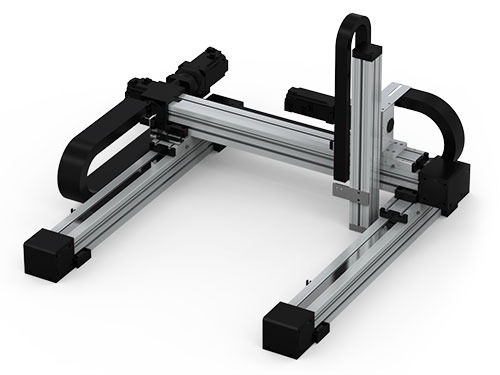

The linear module is a mechanical structure that provides linear motion. It can be used horizontally or vertically. It can also be combined into a specific motion mechanism--that is, multi-axis motion commonly referred to as XY axis, XYZ axis, etc. in the automation industry mechanism.

Linear actuator are play an important role in industrial automation in now days. They have many kinds of uses, they mainly used in machine tools and industrial machinery, also they can be used in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

There are two kinds drive type for linear actuator, one is belt drive linear actuator, the other is ball screw drive linear actuator. Today we will introduce the information about belt drive linear actuator.

How is belt drive linear actuator composed?

Belt linear actuator is mainly composed of: belt, linear guide rail, aluminum profile, coupling, motor, sensor, etc.

How does a belt drive linear actuator work?

The belt is mounted on the pulley block on either side of the linear actuator, and servo motor is mounted with the pulley block. When the input is in use, main carriage is driven by the belt. The belt linear actuator is usually designed specifically to control the tightness of the belt on one side, which facilitates the debugging of the equipment during production.

How accurate are belt drive linear actuator?

The precision of the belt driven linear actuator depends on the belt quality and the combination of the assembly process. Control of power input can affect belt accuracy. LIMON belt linear actuator’s positioning accuracy is ±0. 05mm and maximum speed 5 meters per second.

What is the advantage of a belt drive linear actuator?

1. Belt linear actuator are best recognized for their long stroke. In general, using belt drive linear actuator can achieve longer stroke than ball screw drive, and which is more economical. And up to now, LIMON provide the maximum can 12 meters belt linear actuator to our partner.

2. High load carrying capabilities.

3. LIMON provide max 160x160mm belt drive linear actuator, and due to the dimension, this type actuator are widely used in Europen market.

4. When the belt module is combined with multiple axes, it can make the bottom axis to realize the simultaneous movement of the two axes connecting rod.

How is the belt drive linear actuator installed?

Step 1 - Requirements and preparation of installation platform:

1. During the operation of linear units, the platform will be subjected to large impact force, so the installation platform should have sufficient stiffness and stability.

2. If conditions permit, the contact area between the linear units base and the installation platform shall be increased as much as possible.

3. Please ensure that there are no foreign matters, burrs and other items on the installation platform that may hinder the installation of the module before installation.

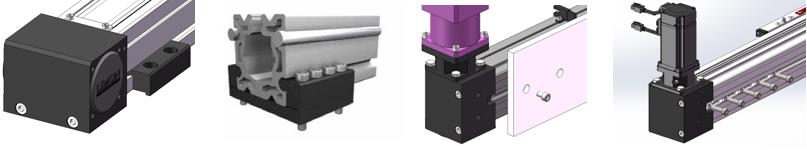

Step 2 - Installation steps of single axis sliding table module:

The installation mode of single axis manipulator can be divided into lock installation and lower lock installation. The appropriate installation mode can be selected according to the current situation of the workbench.

If the locking installation is adopted, first remove the dust cover, pass the Allen screw through the body base of the single axis linear module, and lock it to the screw hole of the installation platform.

If the lower lock installation is adopted, the screw shall pass through the installation platform and the lock shall be attached to the screw hole of the body base.

How to make precision test for belt drive linear actuator?

After the installation of the linear units and confirming whether the operation noise and smoothness are normal, you can choose whether to measure the horizontal and vertical running parallelism of the linear units.

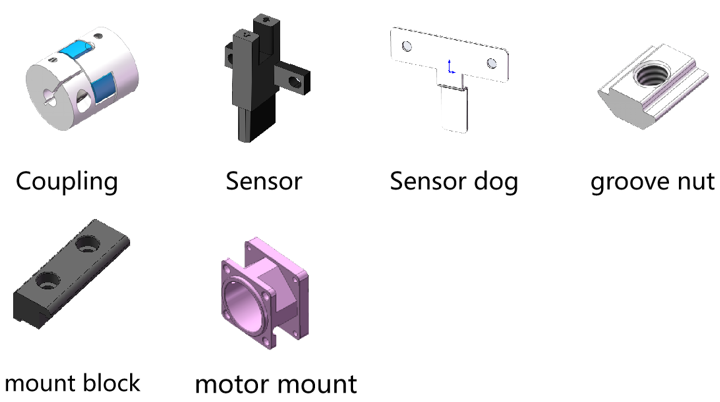

What accessories are used in belt drive linear actuator?

1. Coupling: Used to connect motor and output shaft

2. Sensor & Sensor dog: Normally, there are three photoelectric switches in a sensor set and one sensor dog.

①1pc zero switch: used to reset the moving seat when the motor stops working.

②2pcs limit switches: used to limit the moving seat, which can avoid the moving seat directly hitting the supporting seat.

3. Groove nuts and screws: used for install the linear module into the platform.

For the belt drive linear actuator the most important thing is high precision. LIMON precision grasp is very high, we are not only can provide multi-axis combined project and also can offer customized service. This is why we get good reputation from the market.