1. Keep it Clean:

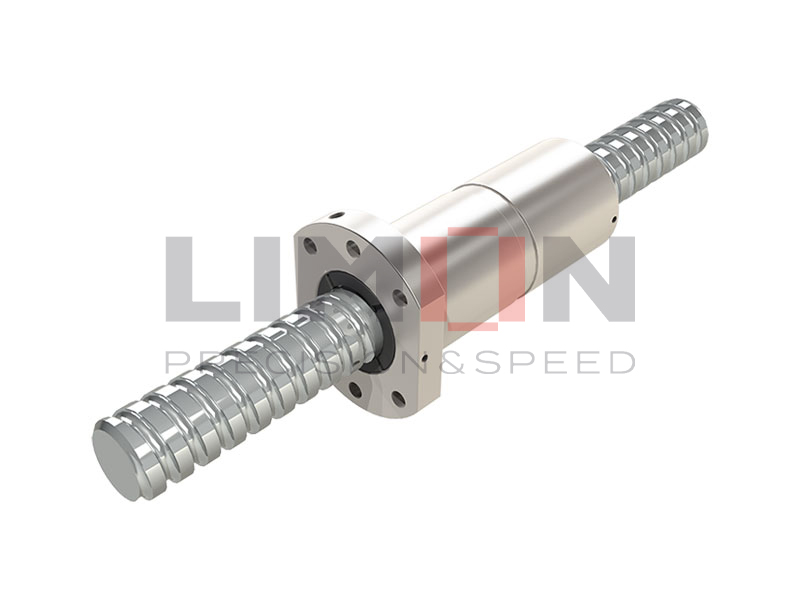

Why: Contaminants such as dust, debris, and metal particles can significantly impact the performance of ball screws. Keeping the system clean is crucial to prevent premature wear and reduce the risk of damage to the ball bearings.

Maintenance Tip: Regularly clean the ball screw assembly, paying attention to the exposed parts. Use a mild detergent or a recommended cleaning solution to remove contaminants. Avoid using high-pressure air, as it may force particles into the ball nut.

2. Lubrication is Key:

Why: Proper lubrication is essential for reducing friction and minimizing wear between the ball bearings and the screw shaft. Insufficient or improper lubrication can lead to increased friction, heat generation, and accelerated wear.

Maintenance Tip: Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants. Ensure that the lubricant is compatible with the operating conditions, and apply it consistently to maintain smooth operation.

3. Check for Backlash:

Why: Backlash, or the clearance between the screw and nut, can affect the precision and accuracy of linear motion. Monitoring and addressing excessive backlash can prevent issues related to imprecise positioning.

Maintenance Tip: Periodically check for backlash using appropriate measurement tools. If backlash exceeds acceptable limits, consult the manufacturer’s guidelines for adjustments or replacements. Addressing backlash issues promptly contributes to improved system performance.

4. Inspect for Wear:

Why: Over time, ball screws may experience wear on the ball bearings, screw threads, or other components. Regular inspections can help identify signs of wear and allow for timely maintenance.

Maintenance Tip: Conduct visual inspections of the ball screw assembly. Look for signs of pitting, scoring, or irregularities on the screw shaft and ball bearings. Replace any worn components according to the manufacturer’s recommendations.

5. Monitor Operating Conditions:

Why: Operating conditions, such as temperature and load, can impact the performance of ball screws. Monitoring these conditions helps identify potential issues and allows for adjustments or modifications as needed.

Maintenance Tip: Keep an eye on temperature variations and load changes during operation. If conditions deviate from the recommended parameters, investigate the cause and make necessary adjustments to prevent excessive wear and stress on the ball screw.

Implementing a proactive maintenance routine for ball screws is crucial for preserving their precision and extending their lifespan. Regular cleaning, proper lubrication, monitoring for backlash and wear, and staying vigilant about operating conditions are key practices to ensure the optimal performance of ball screw systems in industrial settings. Following these maintenance tips can contribute to enhanced reliability and efficiency, ultimately maximizing the value of this critical motion control component.