What is a linear motor?

A linear motor is an electric motor that generates motion in a straight line rather than a rotational movement. Unlike traditional motors, it does not require mechanical conversion to achieve linear motion. Linear motors operate based on electromagnetic principles, offering high precision, speed, and efficiency in various industrial applications.

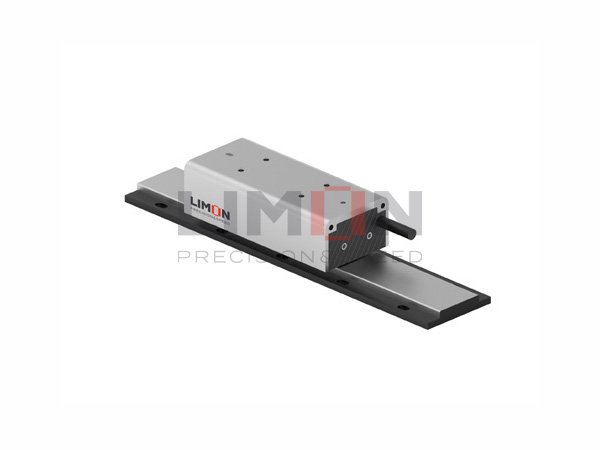

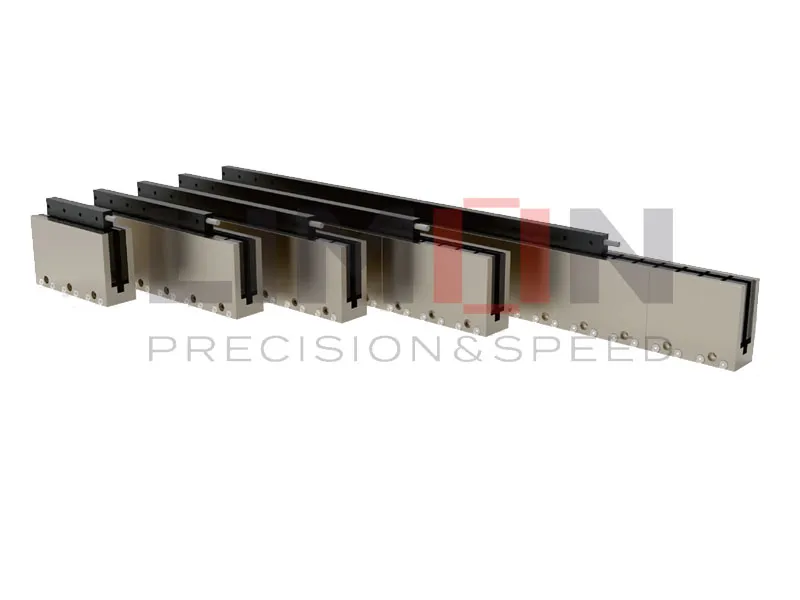

- GLC series: cover the load lower than 20kgs.

- RL series: cover the load from 20-160kgs

- LC series: Ironcore type

- LU series: Ironless type

How does a linear motor work?

A linear motor uses electromagnetic force to directly generate straight-line motion without mechanical conversion, enabling high precision, speed, and smooth operation.

Benefits of Using a Linear Motor Drive

- A linear drive motor offers superior positioning accuracy, rapid acceleration, and smooth movement compared to mechanical transmission systems.

- With no contact between driving components, linear motors have minimal wear, require less maintenance, and provide consistent performance over long service life.

- Achieve micron-level repeatability, handle high-speed cycles, and operate silently, making them ideal for cleanroom and high-tech manufacturing environments.

- Eliminate backlash, enhance motion stability, and can be integrated into compact, space-saving designs.

For a deeper understanding of why linear motors outperform other systems, let’s examine their components, costs, and applications.

What is the core component of a linear motor?

The core component of a linear motor is the combination of the primary part (stator) and the secondary part (rotor), which together generate electromagnetic thrust. In LIMON’s linear motor actuator series, such as the GLC and RL series, the primary component contains coils and the secondary part contains permanent magnets. When electric current passes through the coils, a magnetic field interacts with the magnets to create linear force. Unlike ball screw driven linear actuators, which require rotary-to-linear conversion, the linear drive motor delivers motion directly. This direct-drive principle reduces friction and backlash, resulting in extremely high positioning accuracy—up to ±2μm in some models. The core also often includes integrated guidance systems to maintain stability and prevent side loads, making it suitable for precision-critical industries like semiconductor manufacturing and laser processing.

Why is a Linear Motor more expensive than a Ball Screw Linear Actuator?

A linear motor generally costs more than a ball screw driven linear actuator due to its advanced technology and performance advantages. Ball screw linear actuators convert rotary motion into linear motion mechanically, using a ball screw and nut system. They are efficient, durable, and cost-effective for many industrial uses. However, they have inherent mechanical contact, which leads to wear, maintenance needs, and limitations in speed.

Linear motors, by contrast, have no mechanical contact in the drive mechanism, which eliminates backlash, minimizes maintenance, and allows ultra-high speed and acceleration. Their precision levels are superior, often achieving micron or sub-micron repeatability. The manufacturing of high-grade magnets, precision winding of coils, and integrated feedback systems adds to the cost. Additionally, linear motors require high-performance control electronics to achieve their potential, further increasing system price. The higher upfront investment is justified in applications where precision, speed, and longevity are critical.

Where is a linear motor axis used for?

Linear motor axes are widely used in industries that demand high speed, high accuracy, and smooth motion. In manufacturing, they are common in semiconductor wafer handling, LCD panel production, and photovoltaic cell assembly. Precision machining applications use linear motor actuators for contouring and milling operations where micron-level accuracy is required. They are also used in inspection equipment, laser cutting and engraving, high-speed pick-and-place systems, and medical device production. LIMON’s linear motor driven modules, like the RLO and PSA series, are designed to excel in cleanroom environments, delivering silent operation and minimal particle generation. These qualities make them ideal for electronics, optical assembly, and biotechnology processes. Compared to ball screw driven linear actuators, linear motor systems can handle applications with extremely fast cycle times and delicate product handling, without the wear and vibration associated with mechanical drives.

In summary, linear motors deliver unmatched precision, speed, and smoothness in industrial motion control.