Proper maintenance is essential to ensure the longevity and optimal performance of linear guides, whether they feature an aluminum linear guide rail, CNC linear guide rail, or heavy-duty linear guide rails. Users seeking guidance on lubrication, cleaning, and general care will find these key practices instrumental in preserving the efficiency of their linear guide systems.

Lubrication for Smooth Operation

Regular lubrication is paramount for linear guides, especially those with linear guide bearings. Applying lubricant to the linear guide block and carriage enhances the frictionless movement of these crucial components, contributing to a smoother glide along the guide rail.

Precision Preserved with Cleanliness

Cleaning is a fundamental aspect of linear guide maintenance. Regularly remove debris and contaminants from the linear guide rail and carriage to prevent wear and ensure precision in linear motion. This practice is essential for systems like precision linear guides that demand meticulous cleanliness.

Comprehensive Care for System Longevity

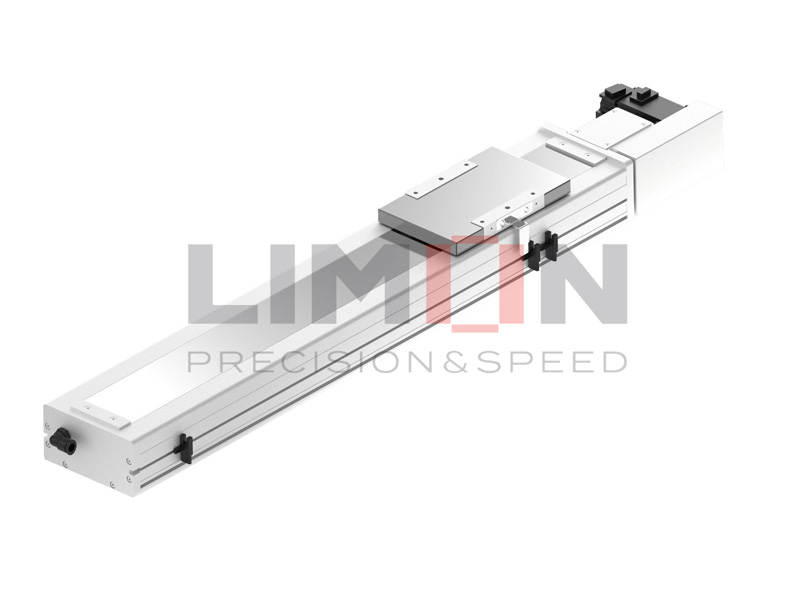

General care involves a holistic approach to maintaining linear guides. This includes inspecting the entire linear guide system, from the linear guide shaft to the linear guide slider, ensuring that all components are in optimal condition. Implementing a routine check-up schedule contributes to the long-term reliability of the linear guide.

Adaptability in Maintenance

Linear guides, whether square linear guides or slide linear guides, boast adaptability in maintenance practices. Users can tailor their care routines to suit the specific requirements of their chosen linear guide system, whether it features a linear guide vs box way configuration.

Guidelines for Box Guideways vs Linear Guideways

Understanding the distinction between box guideways vs linear guideways is crucial in maintenance. Box guideways may demand different care protocols, and users must be aware of the unique considerations associated with their chosen linear motion system.

Leveraging 3D Models for Maintenance Insights

The use of 3D models in maintenance routines offers a visual advantage. Users can explore linear guideways 3D models to gain insights into the configuration of their systems, aiding in identifying potential areas that require attention.

Choosing Reliable Manufacturers for Maintenance Supplies

When acquiring lubricants, cleaning agents, and replacement parts, opt for products from reputable linear guideway manufacturers. This ensures compatibility and adherence to quality standards, contributing to effective and reliable maintenance.

Budget-Friendly Maintenance Solutions

While prioritizing quality, users can explore cost-effective maintenance solutions. For instance, when considering linear guideways price in terms of lubricants or cleaning agents, there are budget-friendly options without compromising on performance.

In conclusion, a proactive approach to the maintenance of linear guides is crucial for sustaining peak performance. Whether it’s regular lubrication, meticulous cleaning, or general care, these practices contribute to the overall health and efficiency of linear guide systems, ensuring they remain reliable components in precision machinery.