Installing linear guides is a crucial step in ensuring the smooth and precise linear motion of machinery. As users embark on the installation process, incorporating essential components like the aluminum linear guide rail and CNC linear guide rail is key to achieving optimal performance.

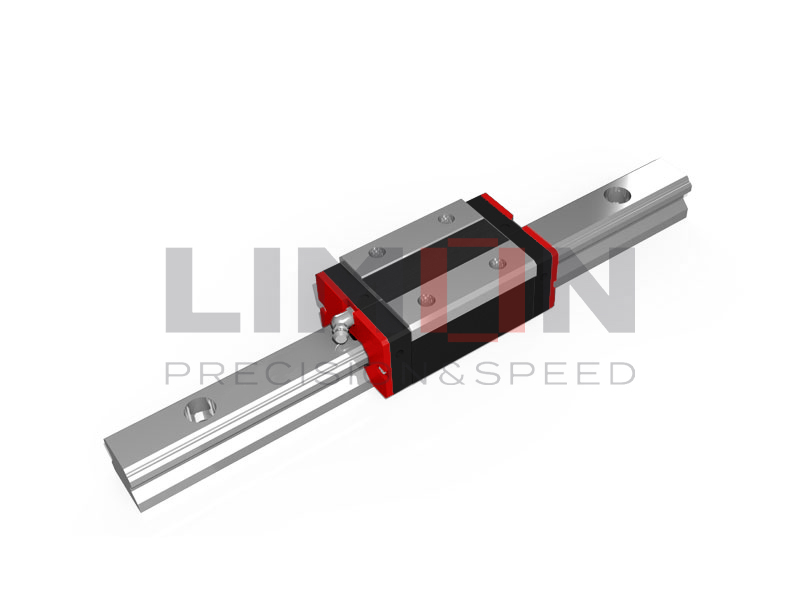

Foundation for Stability: Begin the installation by securing the aluminum linear guide rail firmly in place. This sturdy foundation sets the stage for the entire linear guide system, providing stability for subsequent components.

Enhancing Precision with CNC Technology: Integrate the CNC linear guide rail seamlessly into the installation process. This precision-enhancing technology ensures that the linear motion is not only stable but also incredibly accurate, meeting the demands of precision-driven applications.

Heavy-Duty Support: For applications involving substantial loads, the integration of heavy-duty linear guide rails is imperative. These robust components, designed for durability, contribute to the system’s overall load-bearing capacity.

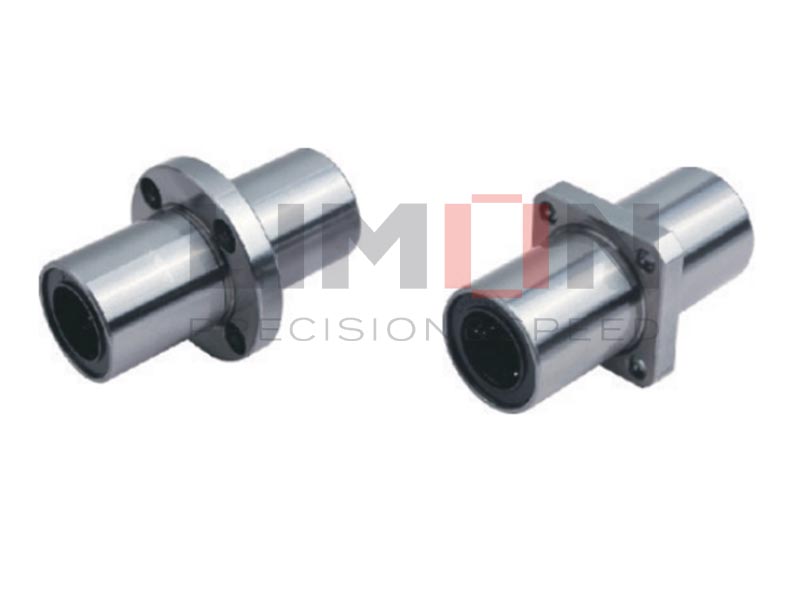

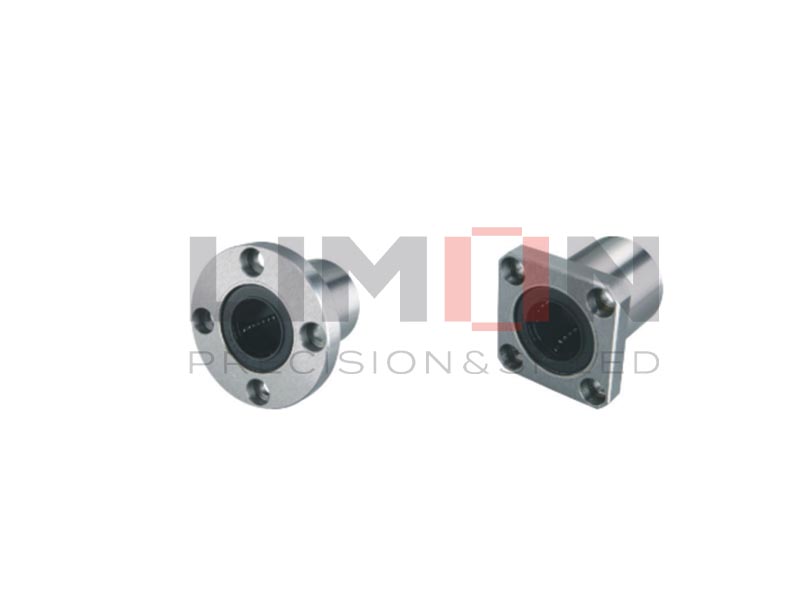

Strategic Placement of Bearings: Carefully position linear guide bearings along the guide rail, ensuring optimal spacing for frictionless movement. This step is crucial for achieving the smooth glide that linear guides are known for.

Encapsulating Motion: Assemble the linear guide block or carriage, encapsulating the linear guide bearings. This component is the linchpin, connecting the linear guide system to the moving elements of the machinery.

Seamless Integration of Rail and Carriage: In systems employing linear guide rail and carriage configurations, ensure the seamless integration of these components. The synergy between the rail and carriage is vital for achieving controlled and reliable linear motion.

Completing the System: For comprehensive linear motion solutions, integrate linear guide systems such as square linear guides or slide linear guides. The versatility of these systems allows users to tailor the installation to specific application requirements.

Precision Matters: When deciding between linear guide vs box way configurations, prioritize precision. Linear guideways, with their precision linear guide components, are designed for applications where accuracy is non-negotiable.

Visualizing the Setup: Utilize 3D models of linear guideways during the installation process. These models provide a visual aid, allowing users to foresee potential challenges and fine-tune the placement of components for optimal functionality.

Choosing Reliable Manufacturers: When sourcing linear guideways, opt for reputable linear guideway manufacturers. This ensures that components, from linear guideway rail to linear guide shaft, adhere to industry standards, guaranteeing longevity and performance.

Budget Considerations: While focusing on quality, factor in linear guideways price considerations. Explore cost-effective solutions, such as roller-type linear guideways, without compromising on the performance of the installed system.

In conclusion, the installation of linear guides is a meticulous process that demands attention to detail. By incorporating key components and adhering to best practices, users can ensure that their machinery operates with the precision and reliability that linear guides are renowned for.