We all know that ball screw is the most commonly used transmission element in tool machine tools and precision machinery, so what is the ball screw? What does it do? What are the applications in practice? What should we pay attention to when choosing and using this product? So today we’re going to talk about it.

First, what is the ball screw and how does it works?

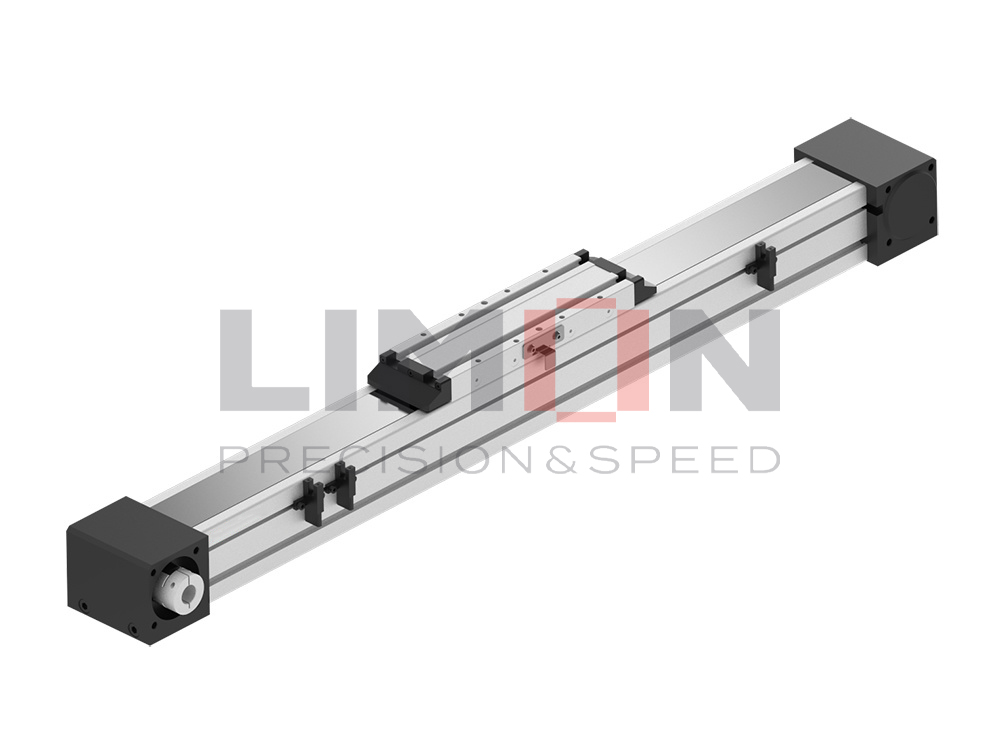

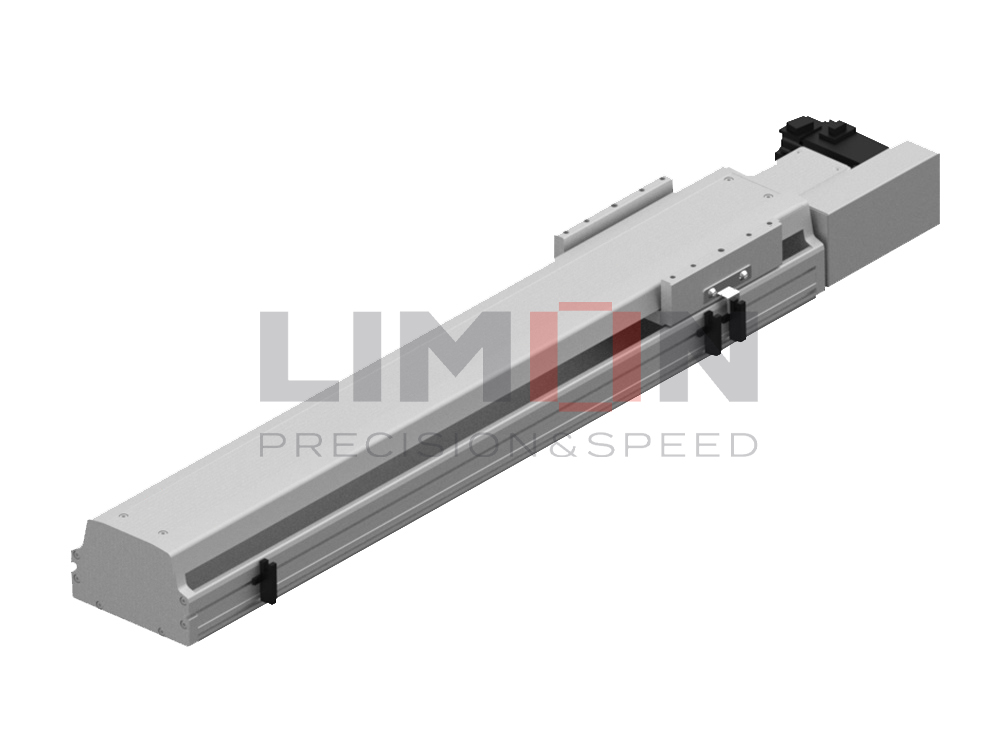

Ball screw consists of screw, nut and ball. Its main function is to convert rotary motion into linear motion or torque into axial repetitive force. It has the characteristics of high precision, reversibility and high efficiency, but also because of its small friction resistance, so it is widely used in a variety of industrial equipment and precision instruments.

Main datas of ball screws:

- Ball screw diameter & lead.

- Length standard: 2 meter ball screw, 3 meter ball screw, maximum length is 6 meter.

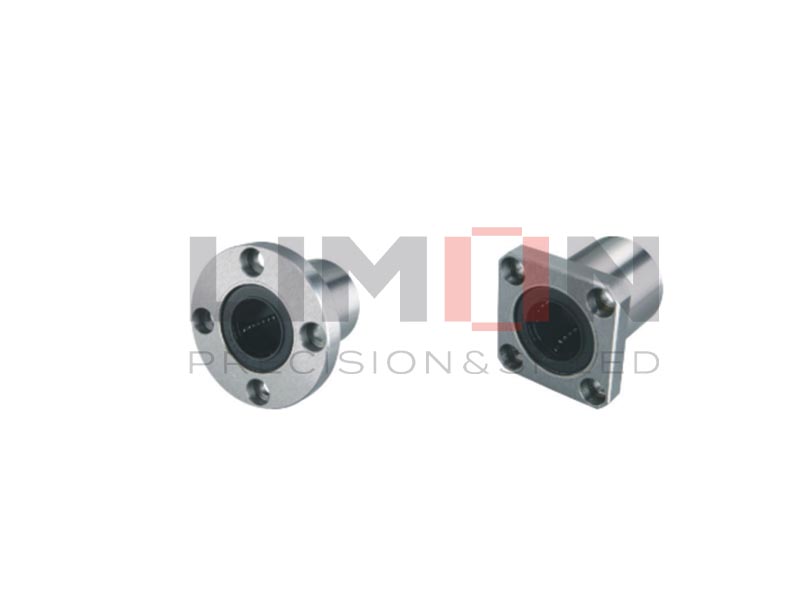

- Nut form: According to the flange form is divided into single cut flange, double cut flange, round flange, no flange nut form. According to the length of the nut into single flange and double flange.

- Precision: C3, C5, C7.

Application industry and equipment of ball screw:

- large processing center: the speed of large machining center tool machine is quite high, so this kind of comprehensive mechanical equipment with relatively high speed needs to use the ball screw with high DN value, which can withstand the huge load in operation.

- general automation machinery: usually only the ball screw is needed to achieve the role of rapid transfer. The requirements for load are not too high, and the general end cover 2 meter ball screw can meet the requirements of such use conditions.

- High processing accuracy requirements machine: such as electronic machinery, CNC machinery and precision tool machine, this kind of use conditions, not only requires to achieve very high processing accuracy, and there are also very high requirements in flexibility, so they need for 2 meter ball screw to achieve high-speed operation requirements.

- Precision electronics:Electronic and electrical industry, semiconductor machinery.

- Small processing machinery.

Matters needing attention when choosing ball screw:

- check and understand the manufacturer’s screw products in advance, including its positioning accuracy, size specifications, support mode, according to the rated dynamic load to determine the size specifications of 2 meter ball screw.

- When ordering 2 meter ball screw, first confirm your production needs, and provide the required pretightening force to the manufacturer according to the force of the screw.

- The preload of the ball screw should be greater than 1/3 of the axial working load, so as to ensure that there is no axial clearance of the screw nut when the 2 meter ball screw bears the maximum axial working actual load.

- Check the screw stability, stiffness, rotational inertia accounting; Check the critical speed of ball screw pair; Calculate the moment of inertia of CNC machine tools; Check the closed-loop control resonance frequency.

Some popular ball screw manufacturers except LIMON:

Japanese brands: NSK, THK, KSS, Kuroda, etc.

Taiwan brands: TBI, HIWIN, PMI, GTEN,etc.

European brands: REXROTH, SKF, MISUMI, etc.