When it comes to linear motion systems, the choice between a belt driven linear actuator and a ball screw linear actuator can significantly impact your machine’s performance, cost-efficiency, and longevity. Each technology has unique strengths tailored to specific industrial needs.

What is a Belt Driven Linear Actuator?

A belt driven linear actuator is engineered for high-speed, long-stroke applications. It uses a timing belt system to convert rotary motion into linear motion, making it ideal for fast, continuous motion with minimal noise.

Key Benefits:

-

High-speed performance

-

Quiet operation

-

Low maintenance

-

Perfect for long travel distances

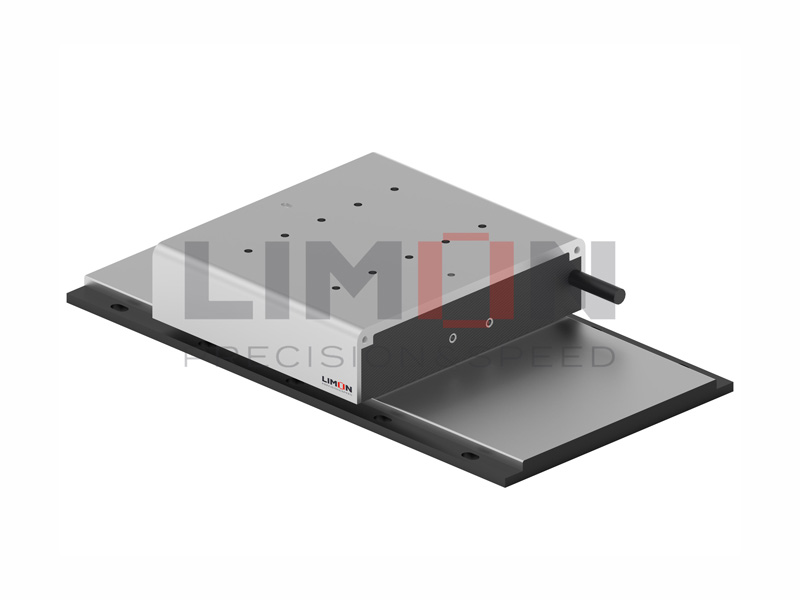

What is a Ball Screw Linear Actuator?

A ball screw linear actuator provides exceptional accuracy, repeatability, and load-bearing capacity. Its screw-driven mechanism offers minimal friction, ensuring consistent and precise movement—perfect for demanding automation systems.

Key Benefits:

-

High precision and repeatability

-

Superior rigidity and load capacity

-

Smooth, consistent motion

Side-by-Side Comparison: Belt vs. Ball Screw

| Feature | Belt Driven Linear Actuator | Ball Screw Linear Actuator |

|---|---|---|

| Speed | Fast | Slower |

| Precision | Lower | High |

| Load Capacity | Moderate | High |

| Noise Level | Quiet | May vary |

| Maintenance | Minimal | Requires regular care |

| Ideal Use | Long travel, fast motion | High-precision tasks |

Which Linear Actuator Should You Choose?

The choice boils down to your application’s demands:

-

Choose a belt driven linear actuator if your project requires:

-

Fast, continuous motion

-

Long-stroke travel

-

Lower cost and minimal upkeep

-

-

Opt for a ball screw linear actuator if your system needs:

-

High positioning accuracy

-

Heavy load capacity

-

Smooth and repeatable precision motion

-

LIMON: Your Linear Actuator Specialist

At LIMON, we provide both belt driven and ball screw linear actuators to meet a variety of motion control challenges. Whether you’re building a high-speed automation line or a precision CNC platform, our expert team will guide you to the most efficient, safe, and cost-saving solution.

Contact our technical team today to find the perfect fit for your linear motion system.