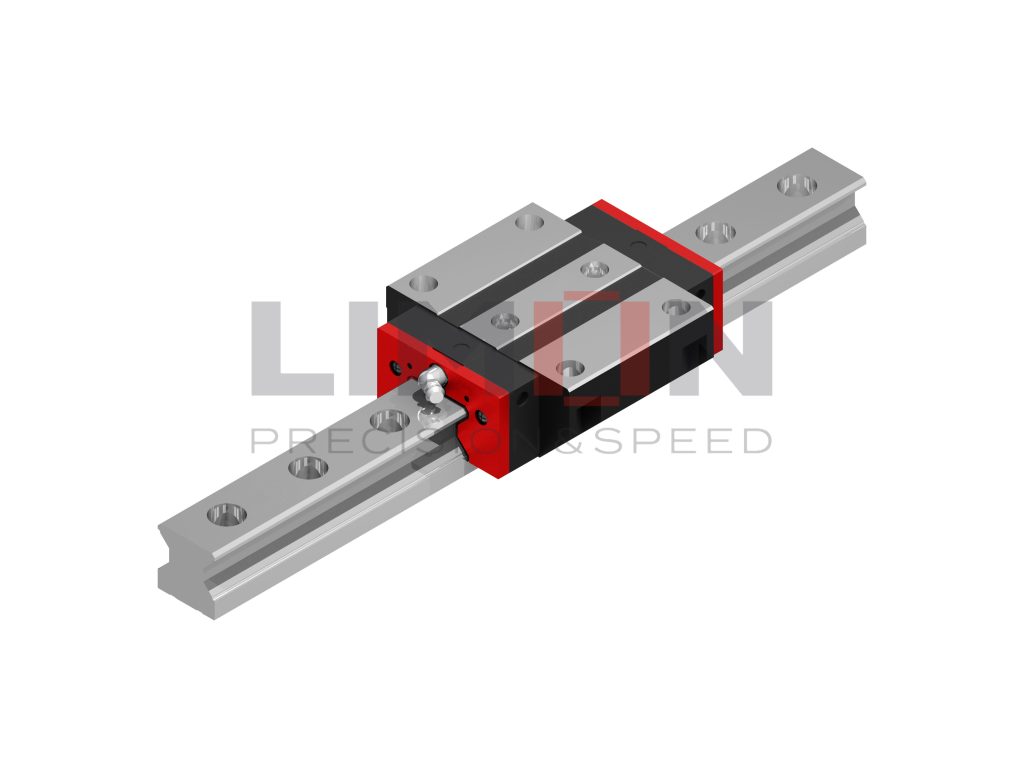

What Are Linear Modules?

Linear modules, also known as linear actuators, are devices that translate rotary motion into highly accurate linear motion. In 3D printing equipment, they are essential for controlling the precise movements of the print head and build platform. The accuracy provided by linear modules is critical for producing detailed and consistent prints.

Precision in 3D Printing with Linear Modules

One of the main advantages of using linear modules in 3D printing equipment is the precision they offer. Precision is vital in 3D printing, where even minor inaccuracies can affect the quality of the final product. Linear modules enable sub-millimeter precision, which is essential for industries requiring high-quality and detailed prints, such as aerospace, medical devices, and consumer electronics.

Enhancing Print Quality and Consistency

Linear modules significantly enhance the quality and consistency of 3D printed products. Traditional systems may suffer from issues like layer misalignment, but the stability provided by linear modules ensures smooth and accurate layer deposition. This leads to superior surface finishes and consistent print quality, which are crucial for both prototyping and production.

Boosting Efficiency and Reducing Downtime

Another key benefit of linear modules in 3D printing equipment is their contribution to efficiency. These modules are built to be durable with fewer moving parts, minimizing the risk of mechanical failure and maintenance needs. This results in less downtime and more reliable, continuous operation. For companies aiming to maximize productivity, the efficiency gains from linear modules are invaluable.

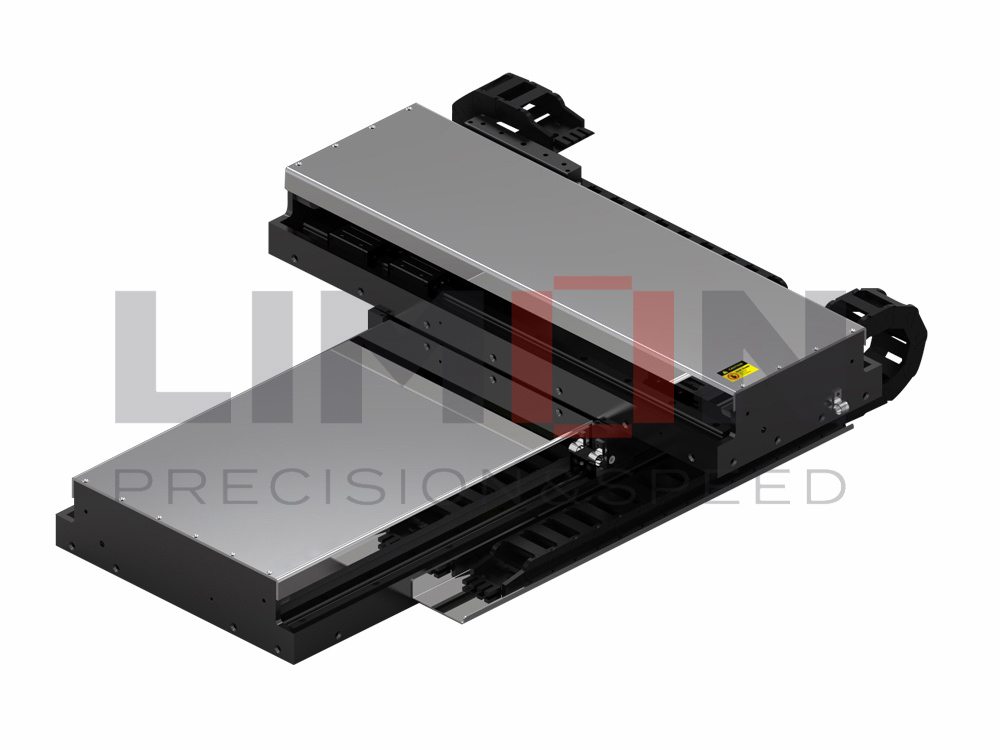

Versatility and Customization in 3D Printing

The versatility of linear modules is another significant advantage. They can be adapted for various 3D printing technologies, including FDM, SLA, and SLS, and are suitable for different sizes of printers, from desktop models to large industrial machines. This adaptability allows for a wide range of applications, from producing large structural components to fine, intricate details.

Future-Proofing 3D Printing Equipment with Linear Modules

As the 3D printing industry advances, integrating cutting-edge components like linear modules becomes increasingly important. They are compatible with modern control systems and smart manufacturing technologies, ensuring that your 3D printing equipment stays up-to-date with industry trends. Investing in linear modules helps future-proof your equipment, making it ready for new advancements and capabilities.

Real-World Impact and Case Studies

I’ve worked with several clients who have successfully implemented linear modules in their 3D printing systems. For example, a healthcare company improved the precision and quality of their medical device prototypes, accelerating their product development process. Similarly, a tech startup specializing in consumer electronics achieved more consistent production quality, reducing material waste and rework.

Conclusion: The Critical Role of Linear Modules in 3D Printing

Linear modules are essential components in 3D printing equipment, providing unmatched precision, efficiency, and versatility. Whether you’re enhancing existing equipment or investing in new technology, incorporating linear modules is a smart move that delivers immediate benefits and prepares your business for future growth.