Overview:

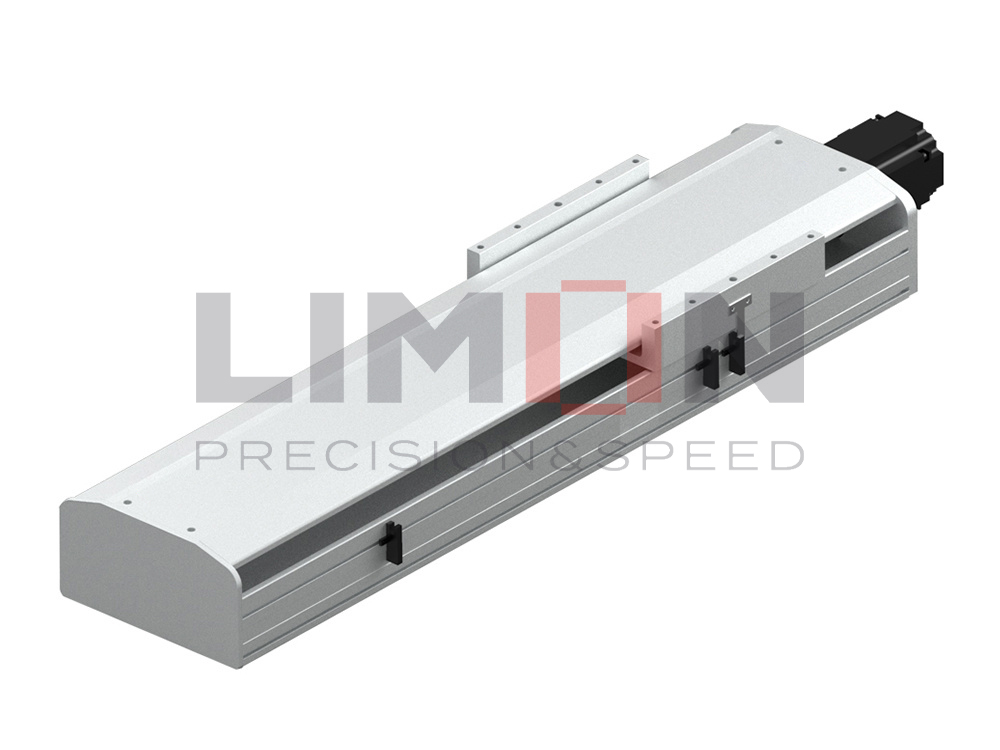

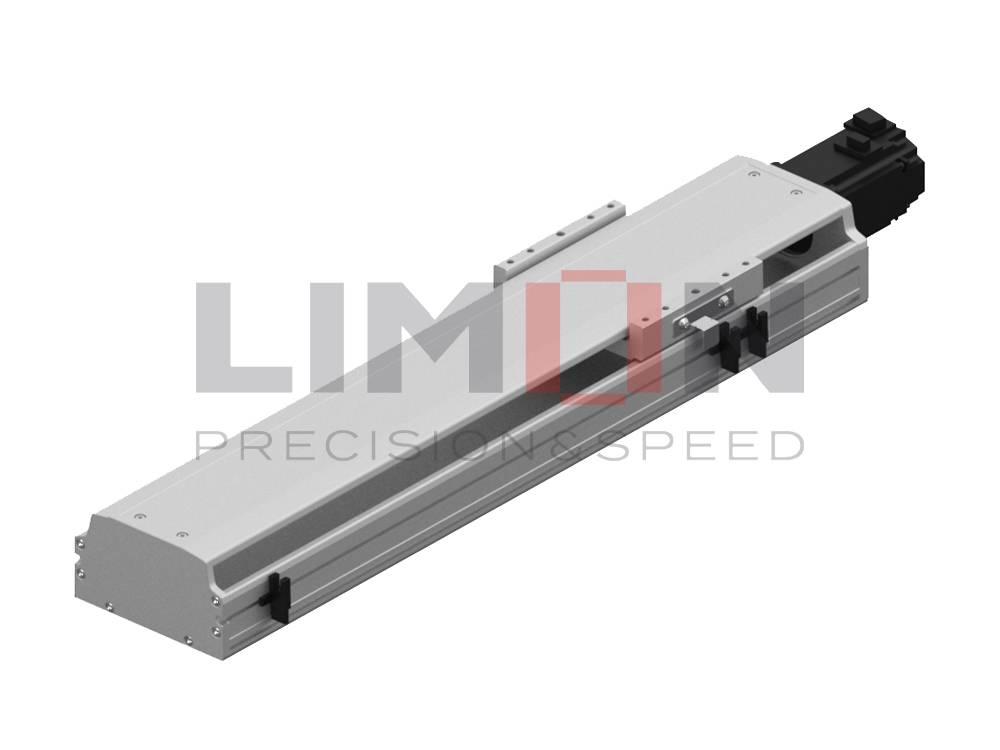

GTC series modules are belt-driven linear actuators, embedded within the guide rails, designed for projects with light loads and limited space usage.

Basic info:

Drive Type: Belt driven type, close type

Stroke: max 1500mm

Characteristics:

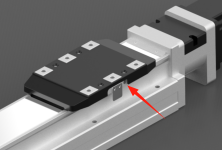

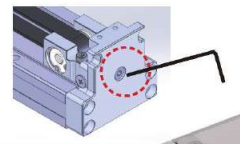

Adjustable Belt Tension

- External belt tension adjustment is possible without disassembly.

Integrated Oil Injection Hole

- By using an external integrated oil injection hole design,all linear blocks can be lubricated at once without the need for disassembly maintenance.

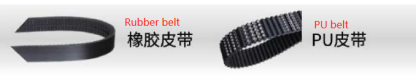

Belt Options

- PU Belt: suitable for clean room environment, produces less dust but is noisy.

- Rubber belt: suitable for general environment, low noise but more dust.

High Precision Embedded Ball Guide

- Grinding after embedded the steel bar, the running straightness and flatness are significantly enhanced.

- Th rails’s pacing width is increased to accommodate more lateral torque.

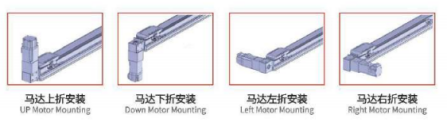

Flexible Motor Collocation

- To increase the flexibility of the machine design, alternative motor brands, powers, and mounting direction can be chosen as needed.

Industry:

- Automated Production Line – Automotive assembly, electronics manufacturing, home appliance production

- Electronics & Semiconductor – Chip packaging, SMT placement, LCD inspection

- Packaging & Logistics – Food packaging, parcel sorting, warehouse automation

- Medical Equipment – Diagnostic instruments, testing devices, surgical robots

- Printing & Advertising – Large-format printing, laser engraving, digital printing

- Research & Laboratory – Lab instruments, sample testing, biotechnology

- Food & Beverage – Filling machines, labeling machines, packaging lines

- New Energy Industry – Lithium battery production, solar panel assembly

-150x150.jpg)