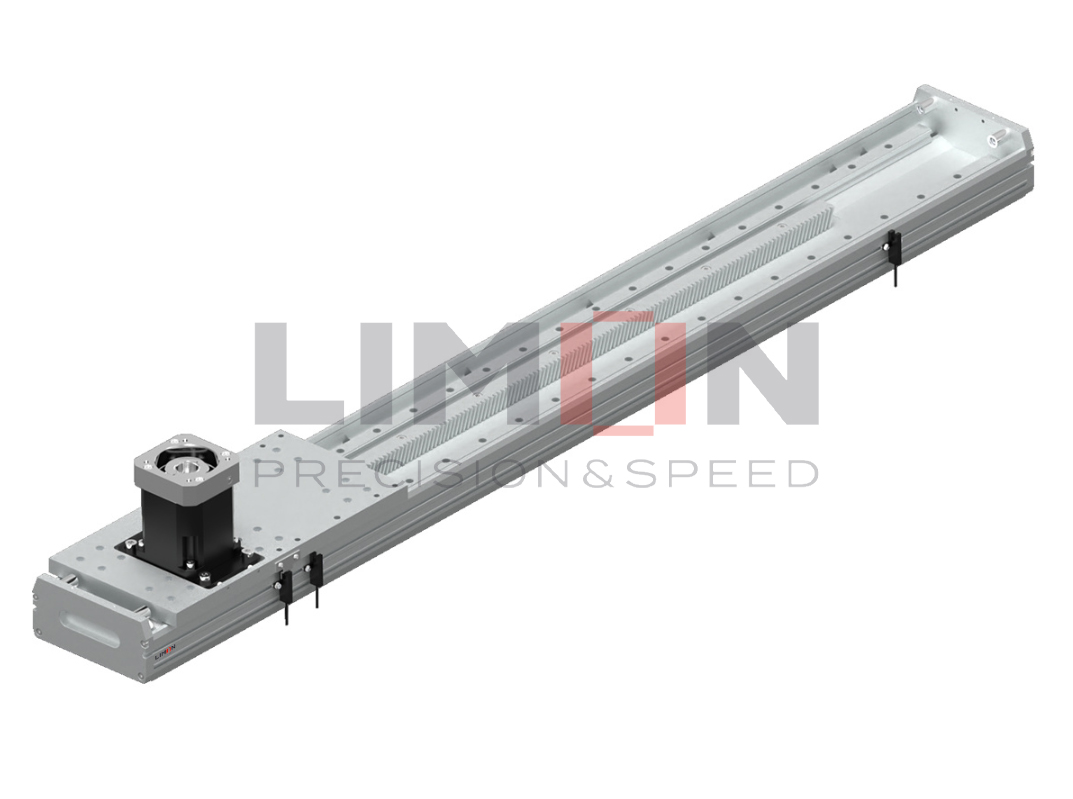

Overview:

YRO series modules are the rack and pinion driven linear actuators. It has higher precision than the belt driven module, can make up for the short stroke of the ball screw driven module, and has a greater load capacity.

Basic info:

Drive Type: Rack and pinion driven type, open type

Stroke: 5500mm(standard), can be joint. (Unlimited)

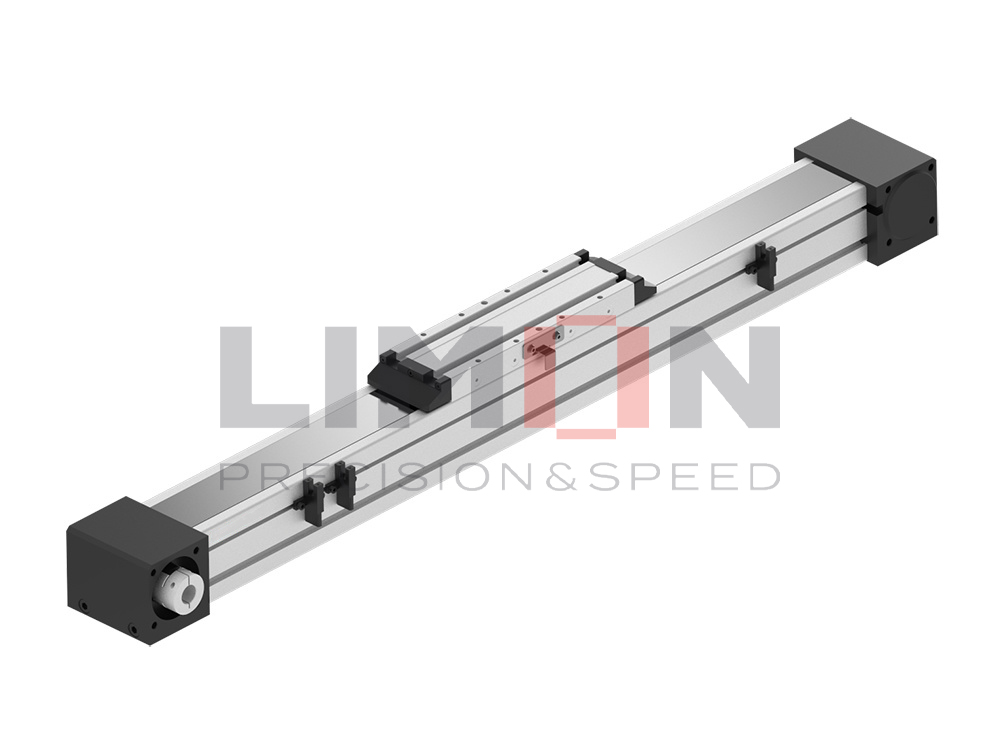

Characteristics:

High Load Capacity

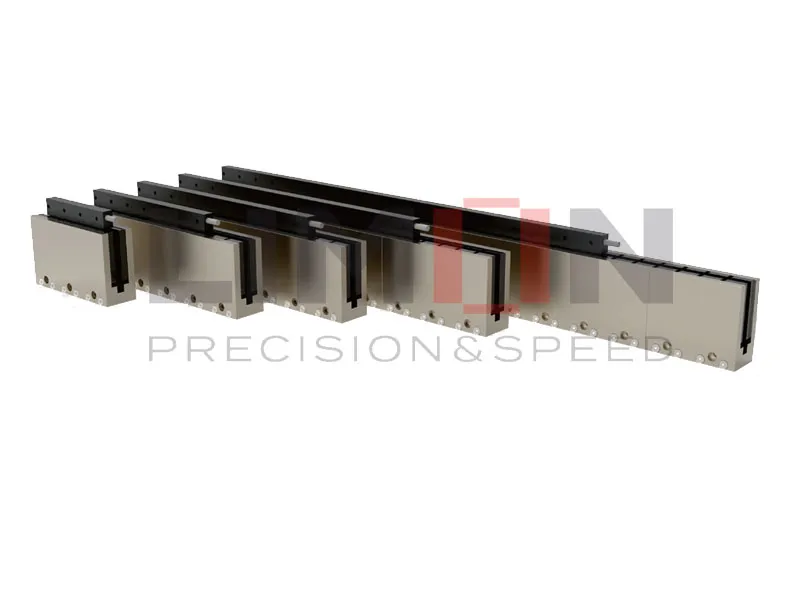

- Rigid Structure: The meshing transmission of gears and racks offers high mechanical rigidity, capable of handling significant radial and axial loads, making it ideal for heavy-duty equipment or high-torque applications.

- Distributed Force: Load is shared across multiple teeth, providing more stable support for heavy workpieces compared to ball screws or belt drives.

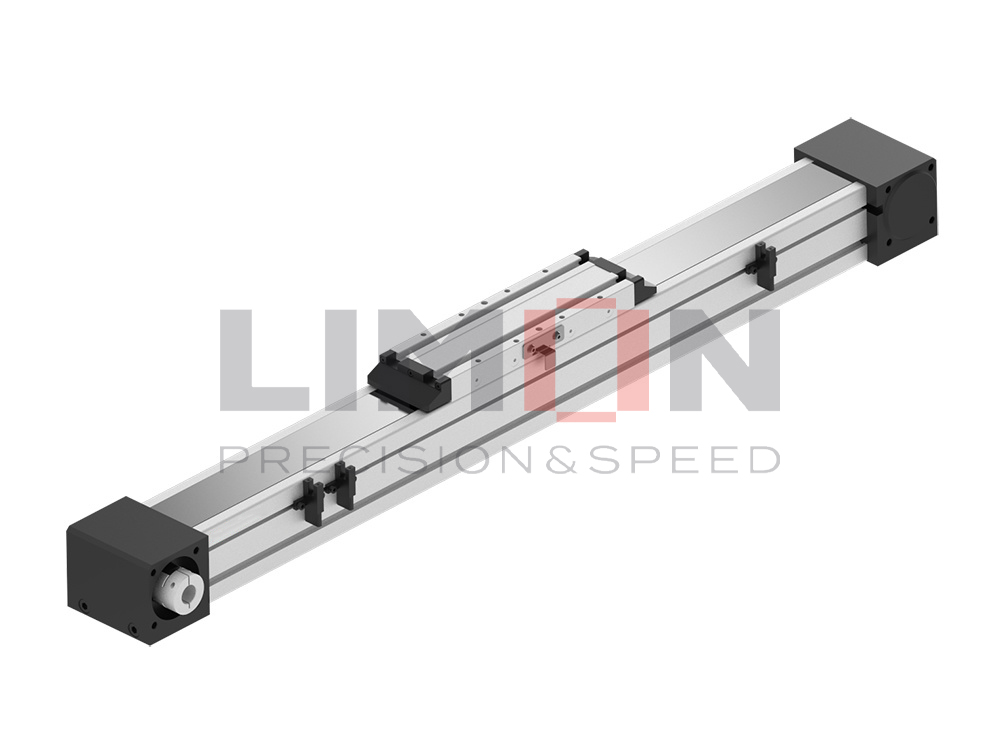

Long Stroke & High Speed

- Unlimited Stroke: By connecting multiple rack sections, ultra-long strokes (e.g., tens of meters) can be achieved, whereas ball screws are limited by length and deflection.

- High-Speed Motion: No inherent speed limit (up to several meters per second), suitable for high-speed reciprocating applications (e.g., gantry systems, laser cutters).

High Precision & Stability

- Precision Meshing: High-precision gear racks (e.g., ground teeth) with backlash elimination (e.g., dual-gear preload) can achieve repeatability of ±0.05mm or better.

- Low Backlash**: Preload or anti-backlash designs minimize play, ideal for high dynamic response (e.g., CNC machines).

Long Lifespan & Low Maintenance

- Wear-Resistant Materials: Gear racks are typically made of alloy steel or hardened surfaces, ensuring minimal wear and extended service life (especially with proper lubrication).

- Maintenance-Free Options: Enclosed modules or self-lubricating racks reduce upkeep frequency.

Flexibility & Modularity

- Versatile Installation: Supports horizontal, vertical, or angled mounting for complex layouts (e.g., vertical lifts in automated warehouses).

- Scalable Design: Easily extended by adding rack sections or integrating multi-axis systems.

Cost-Effectiveness

- Lower Cost for Long Strokes: More economical than ball screws or linear motors for large-scale applications.

- Reduced Maintenance Costs: No frequent belt replacements or screw wear concerns..

Harsh Environment Suitability

- Contamination Resistance: Open designs or protective covers adapt to dusty/oily conditions (e.g., woodworking, metalworking).

- High-Temperature Tolerance: Metal construction outperforms belts in elevated temperatures.

Industry:

- arge-scale Automation Equipment – Automotive welding lines, heavy-duty machine tools, bulk material handling

- Construction Machinery – Crane telescoping arms, excavator slewing mechanisms, aerial work platforms

- Rail Transportation – Subway platform screen doors, high-speed rail maintenance equipment, track inspection devices

- Aerospace – Aircraft door operation, satellite antenna deployment, rocket launch platform adjustment

- Shipbuilding – Hull section positioning, large component assembly, port loading/unloading systems

- New Energy Equipment – Wind turbine pitch control systems, solar tracking mounts, large battery pack assembly

- Military Equipment – Radar lifting systems, missile launchers, armored vehicle transmissions