Inaccurate motor control leads to poor performance, equipment failure, and wasted energy. A servo drive solves this with precision, real-time feedback, and responsive motion control. Here’s what you need to know.

A servo drive is an electronic amplifier that receives command signals and adjusts the power sent to a servo motor based on feedback. It enables precise speed, torque, and position control.

Read on to explore its structure, working principles, and real-world applications.

What is a Servo Drive?

A servo drive is a specialized electronic device used in motion control systems to regulate the operation of servo motors. Its primary function is to receive a control signal from a motion controller or PLC and send a properly modulated current or voltage to the servo motor based on real-time feedback.

Servo drives are essential for achieving:

Precision motion (position, speed, and torque)

Closed-loop control through continuous feedback

Efficient energy usage and system responsiveness

The feedback typically comes from encoders, resolvers, or Hall sensors mounted on the motor. The drive compares this feedback to the desired motion and adjusts motor input accordingly. This process occurs in milliseconds, ensuring high accuracy and real-time correction.

Servo drives are widely used in CNC machinery, robotics, medical devices, and automation systems where complex, high-speed, and high-accuracy movements are critical.

How Do Servo Drives Work?

Servo drives work by forming a closed-loop system that continuously monitors and adjusts the output to the motor based on incoming commands and feedback.

Here’s how the process works:

Command Signal: The controller sends a target position, speed, or torque signal to the servo drive.

Amplification: The servo drive amplifies this signal into appropriate electrical power (voltage or current) for the motor.

Motor Activation: The motor executes the movement accordingly.

Feedback Loop: Encoders or sensors provide real-time feedback on the motor’s actual position, speed, and direction.

Error Correction: The drive compares actual performance with the commanded value. If there’s a discrepancy (error), it instantly corrects the motor input.

Key Components Involved:

Control Logic Circuit: Determines the drive’s response to input signals and feedback.

Power Stage: Amplifies and delivers the necessary energy to the motor.

Feedback Interface: Receives and processes data from position/speed sensors.

Advanced servo drives often include:

PID control algorithms for smooth motion

Communication interfaces (e.g., EtherCAT, CANopen, Modbus)

Built-in safety and diagnostic features

Because of this real-time interaction, servo drives can produce smooth acceleration, deceleration, and high dynamic response, even under varying load conditions.

What is the Purpose of a Servo Drive?

The purpose of a servo drive is to provide accurate control of motion in automated systems by adjusting the energy supplied to a servo motor. It ensures that motors perform precisely according to the system’s demands.

Core purposes include:

Position Control: Ensure the motor reaches and holds the exact position as defined by the controller. This is crucial for applications like robotic arms or pick-and-place machines.

Speed Regulation: Maintains constant or variable speed, regardless of load changes.

Torque Control: Delivers the exact force required for tasks like pressing, drilling, or clamping.

Servo drives also offer:

Error minimization through real-time adjustments

Efficient operation by reducing unnecessary energy use

System protection through current limiting, thermal overload, and short-circuit prevention

In systems requiring high precision and repeatability, such as laser cutting machines or surgical robots, servo drives are indispensable. They not only improve performance but also increase the lifespan and safety of motion components.

Types of Servo Motors

A servo drive is designed to control various types of servo motors, each with unique characteristics suited to different applications. Understanding these motor types helps in selecting the right drive-motor pairing.

1. AC Servo Motors

These are the most common in industrial automation. They operate on alternating current and offer high speed, torque, and accuracy.

Features:

Good for high-load, high-speed applications

Typically paired with encoders

High energy efficiency

2. DC Servo Motors

Operate on direct current, and often used in simpler systems like educational robotics or light-duty automation.

Features:

Simple control mechanism

Low cost

Shorter lifespan compared to AC types

3. Brushless DC (BLDC) Servo Motors

Combine the best of AC and DC motors. They use electronic commutation and have no brushes, making them low-maintenance.

Features:

High reliability and lifespan

Ideal for precision tasks (medical, drones)

Requires compatible servo drives with Hall sensor inputs

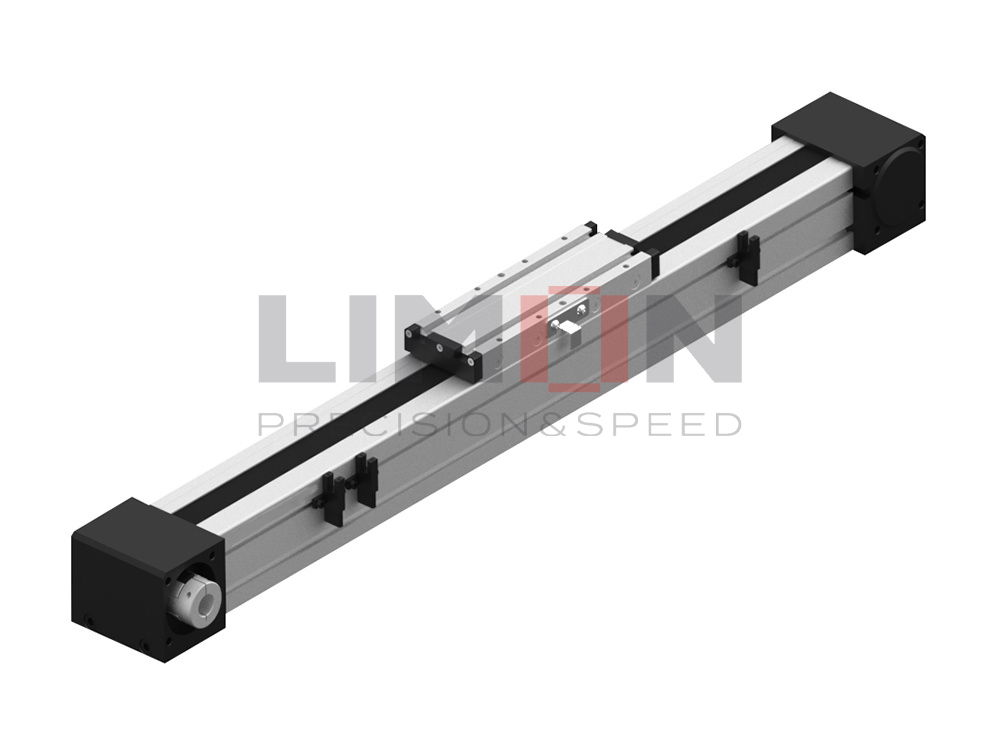

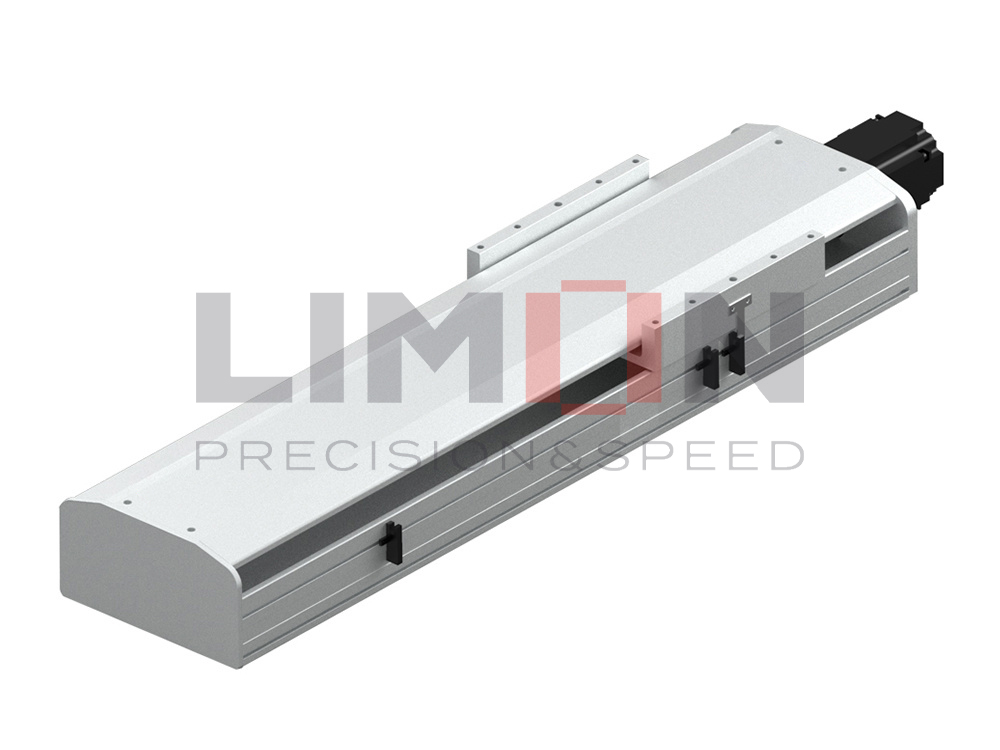

4. Linear Servo Motors

These provide direct linear motion rather than rotary output. Perfect for high-speed applications like semiconductor processing or precision cutting.

Features:

Direct drive = no mechanical backlash

Extremely fast response

Expensive but highly accurate

5. Synchronous/Asynchronous Servo Motors

Used in high-power applications, especially when combined with regenerative servo drives.

Choosing the correct servo drive requires compatibility with the motor type, control interface, voltage, and feedback sensor system.

Why You Should Use a Servo Drive?

Using a servo drive in your motion control system offers significant performance, safety, and efficiency benefits compared to open-loop or simple motor controllers.

1. Precision Control

Servo drives allow for exact positioning and motion down to microns, which is essential in applications like 3D printing, optical inspection, or robotic surgery.

2. High-Speed Response

They can react to commands or disturbances within milliseconds, supporting high-frequency dynamic control in automation environments.

3. Energy Efficiency

Drives regulate voltage and current precisely, minimizing power loss, and can also include regenerative braking to recycle unused energy.

4. Customization and Flexibility

Many servo drives offer programmable logic, PID tuning, and multiple communication interfaces—allowing integration into complex systems.

5. Diagnostics and Safety

Modern drives include fault detection, overload protection, and operational logs. This improves uptime and simplifies maintenance.

6. Versatility

They are used in:

CNC and industrial robots

Packaging and labeling

Automated inspection systems

Aerospace and defense controls

Medical device actuation

In summary, a servo drive turns a motor into an intelligent, feedback-driven component that can adapt and respond to real-world conditions with unmatched precision.

Summary

Servo drives deliver intelligent, closed-loop motion control—empowering motors with precision, responsiveness, and efficiency across demanding industrial systems.For further questions please contact [email protected]