1. Precision Grade Classification of Roller Lead Screws

The precision grade of roller lead screws is primarily defined by lead error per 300mm stroke. Globally accepted standards include ISO, DIN, and JIS, with classifications as follows:

C0 Grade: Error ≤ ±3.5μm/300mm

Ideal for ultra-precision applications such as aviation systems and photolithography machines.C1–C3 Grade: Error ±5–8μm/300mm

Widely used in CNC equipment and humanoid robots, including the Tesla Optimus linear actuator.C5–C7 Grade: Error ±12–52μm/300mm

Applied in industrial automation and general machinery.C10 Grade: Error ±210μm/300mm

Suitable for low-precision scenarios like conveyor systems.

2. How Structural Design Influences Lead Screw Accuracy

The structural type of a roller lead screw has a direct impact on its precision performance. Key types include:

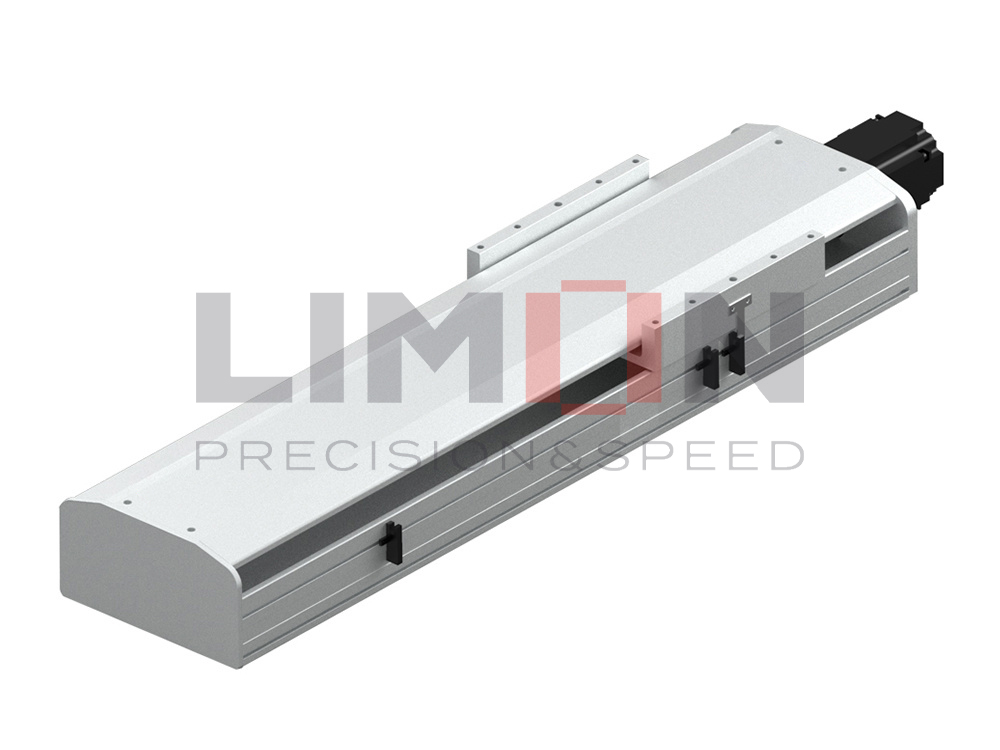

• Standard Type – RGT Series

Non-circulating roller design

Accuracy up to C1 (±5μm)

Ideal for high-speed, high-load use, such as aerospace actuators

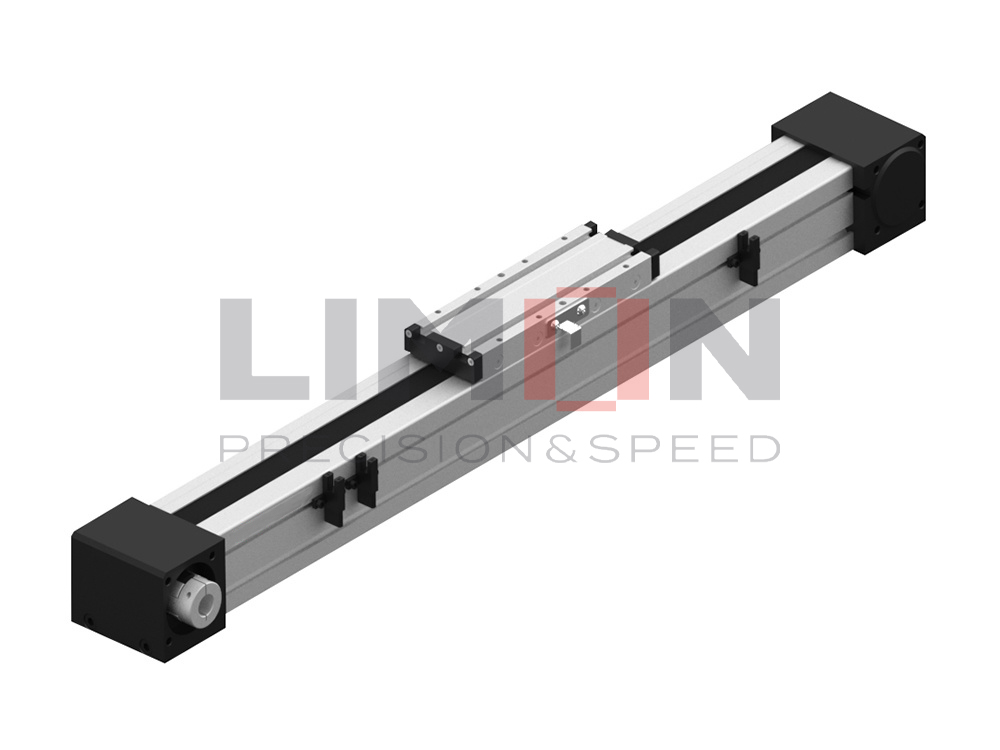

• Reverse Type – RGTI Series

Rollers rotate around the lead screw

Complex nut threading but compact design

Maintains C2 grade (±6μm)

Tesla Optimus adopts this structure for joint actuation

• Circulating Type – RGTR Series

Uses cam mechanism to reset rollers

Delivers ultra-high C0 grade precision

Suited for precision positioning in high-end machine tools

Manufacturing cost is significantly higher

3. Manufacturing Process and Material: The Backbone of Precision

• Grinding Process

For C3 grade and higher, precision grinding is essential. Thread pitch error must be held within ±1μm, often relying on high-end equipment like German SMS grinders.

• Material Quality

Preferred: Cr/Mo alloy steel – minimizes heat treatment deformation.

Challenge: Domestic materials often suffer from banded segregation, causing precision inconsistency.

Reality Check: Only 50% qualification rate for C5-grade lead screws due to material variability.

• Assembly Consistency

Roller screws require 6–8 precisely synchronized threads.

4. Application Scenarios: Matching Precision to Purpose

• High-Precision Applications

Humanoid robot joints (C1–C3)

Semiconductor and optics equipment (C0)

Recommended: Reverse or circulating roller lead screws

• Standard Machinery

C5–C7 rolling-process screws meet general needs

Caution: Service life is only one-third compared to ground lead screws

Final Thoughts: Why Roller Lead Screws Matter

If you’re engineering humanoid robots, aerospace drives, or semiconductor tools, understanding the precision differences of roller lead screws isn’t optional—it’s critical. Their stiffness, accuracy, and durability make them a superior alternative to ball screws when it matters most.

2.jpg)