In the realm of industrial machinery and automation, linear guides are indispensable for ensuring seamless and precise motion. Also known as linear motion guides or slides, these components are pivotal across various sectors, from manufacturing and robotics to aerospace. In this SEO-friendly article, we’ll explore different types of linear guides, their distinct features, and the wide array of applications that benefit from their use.

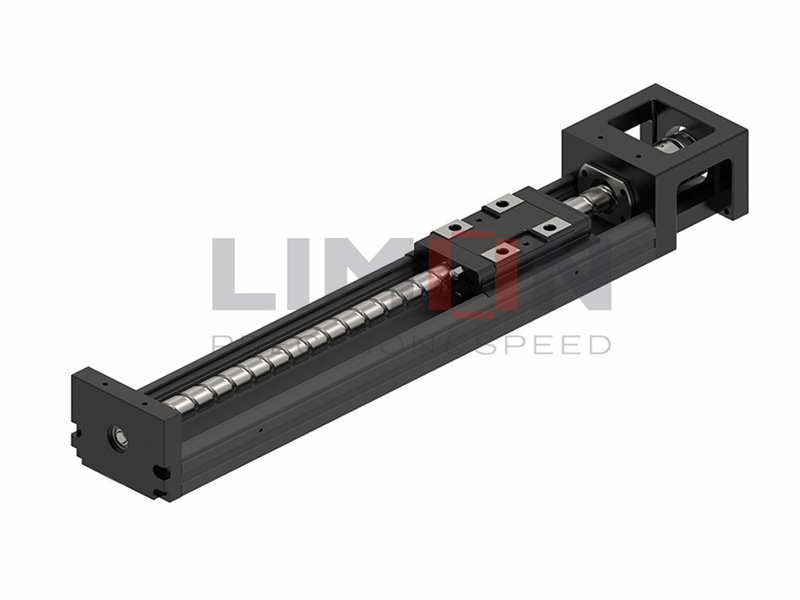

Ball Bearing Linear Guides for Precision Performance:

Discover the reliability and precision of ball bearing linear guides. Ideal for applications requiring accuracy and repeatability, these guides with ball bearings are commonly found in CNC machining, 3D printing, and semiconductor manufacturing.

Roller Linear Guides: Heavy-Duty Solutions for Rigorous Environments:

Uncover the strength and durability of roller linear guides. With increased load-carrying capacity and enhanced rigidity, these guides excel in heavy-duty machinery applications, including industrial presses, material handling systems, and machine tools.

Needle Roller Linear Guides: Space-Saving Precision:

Explore the compact yet robust design of needle roller linear guides. Perfect for applications with space constraints, such as medical devices and precision instruments, these guides deliver high load capacity in confined spaces.

Magnetic Linear Guides: Friction-Free Reliability for Clean Environments:

Dive into the world of magnetic linear guides, where friction and wear are virtually eliminated. These guides are ideal for cleanroom environments, providing enhanced durability and reliability in applications where contamination is a concern.

Dovetail Linear Guides: Stability and Precision in Unique Design:

Unlock the precision and stability of dovetail linear guides. With their unique interlocking wedge-shaped surfaces, these guides are preferred in applications demanding high stiffness and resistance to vibration, such as optical and laser systems.

Rack and Pinion Linear Guides: Swift Motion for High-Speed Applications:

Delve into the efficiency of rack and pinion linear guides. Designed to convert rotary motion into linear motion, these guides are perfect for applications requiring high-speed, long-distance travel, such as CNC routers, laser cutting machines, and automotive assembly lines.

Choosing the right linear guide is pivotal for meeting the specific needs of diverse applications. Whether it’s achieving precision, handling heavy loads, or operating in challenging environments, the world of linear guides offers a solution tailored to each requirement. As technology continues to advance, innovative linear guide designs will undoubtedly shape the landscape of automation and machinery across various industries. Explore the possibilities and stay ahead in the evolving world of linear guides.