The Early Days of Ball Screw Technology: Simple Yet Effective

The origins of ball screws can be traced back to the early 20th century. Back then, ball screws were relatively simple devices designed to convert rotational motion into linear motion with minimal friction. The concept was revolutionary at the time, offering a level of precision that was previously unattainable with traditional lead screws. But as industries demanded higher accuracy and efficiency, ball screw technology had to adapt.

The Modern Era of Ball Screws: Precision and Reliability

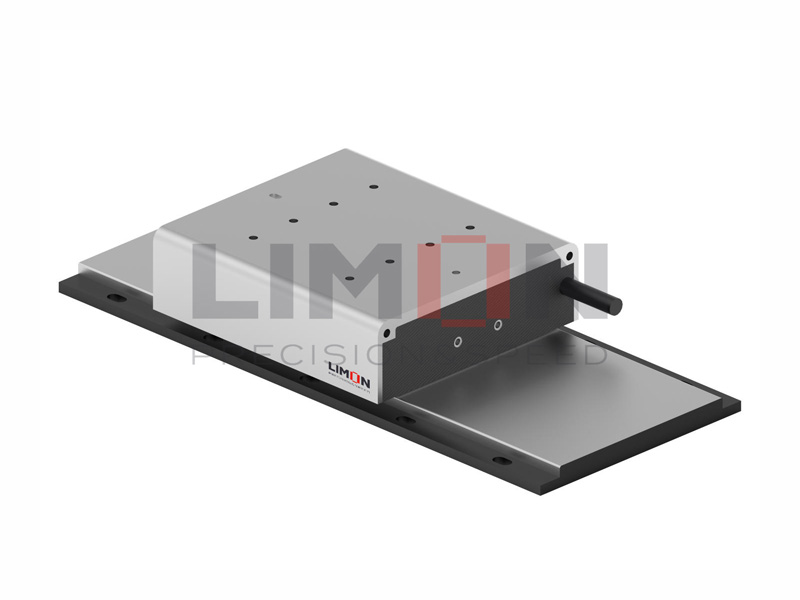

Fast forward to today, and ball screws have become the cornerstone of precision engineering. The advancements in materials, manufacturing processes, and design have transformed ball screws into highly reliable and efficient tools. Modern ball screws offer:

- High Load Capacity: Advances in metallurgy and design have allowed for ball screws that can handle significantly higher loads while maintaining precision.

- Improved Accuracy: With the advent of CNC machining and advanced measurement techniques, we can now produce ball screws with incredibly tight tolerances, ensuring consistent performance in even the most demanding applications.

- Enhanced Durability: Coatings, treatments, and improved lubrication methods have greatly extended the lifespan of ball screws, reducing maintenance needs and downtime.

The Future of Ball Screw Technology: Smart Ball Screws and Beyond

So, where do we go from here? As someone deeply invested in the future of manufacturing technology, I see several exciting trends that will shape the next generation of ball screws.

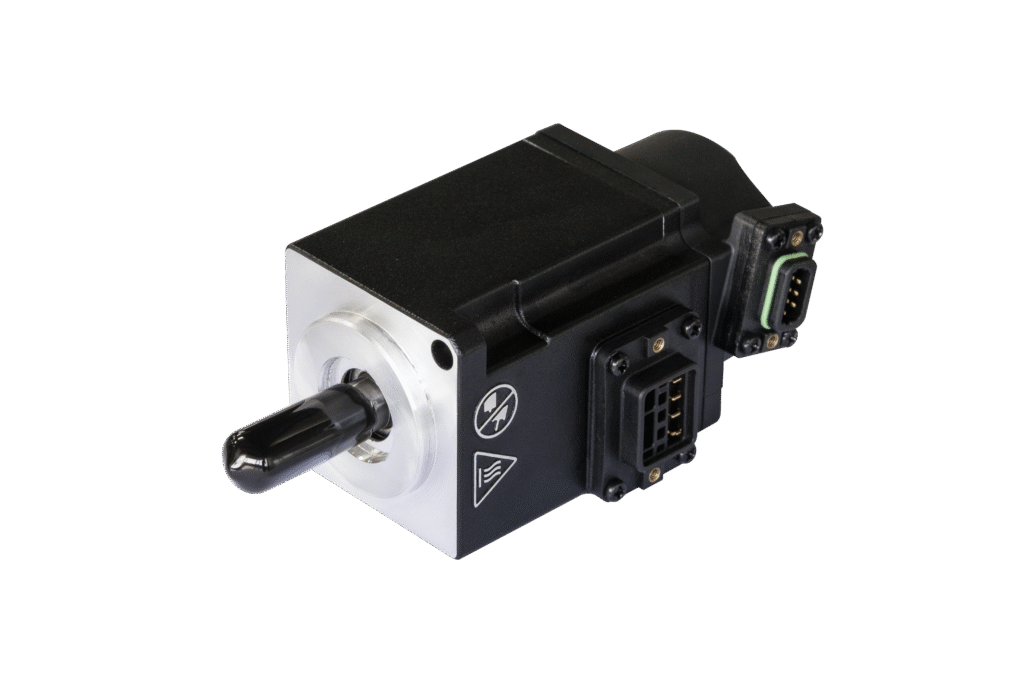

1、Integration of Smart Technology in Ball Screws: The rise of the Internet of Things (IoT) is set to revolutionize ball screw technology. Imagine ball screws equipped with sensors that can monitor performance in real-time, predict failures, and optimize lubrication schedules automatically. This level of intelligence will significantly reduce downtime and increase efficiency across the board.

2、Additive Manufacturing for Ball Screws: 3D printing and additive manufacturing are poised to change how we produce ball screws. By leveraging these technologies, we can create custom designs that are lighter, stronger, and more efficient than ever before. This will open up new possibilities for specialized applications where traditional manufacturing methods fall short.

3、Sustainability in Ball Screw Production: As the industry shifts towards more sustainable practices, I believe we will see ball screws made from recycled materials or designed for easier recycling at the end of their life cycle. This will not only reduce environmental impact but also lower costs in the long run.

4、Miniaturization of Ball Screws: The demand for smaller, more precise components is growing, particularly in the medical and electronics industries. The future of ball screws will likely include even more miniaturized versions, offering the same level of precision and reliability in a much smaller package.

Why This Matters to Your Ball Screw Applications

If you’re in the business of manufacturing, automation, or any industry that relies on precision motion control, keeping an eye on the evolution of ball screw technology is crucial. The innovations on the horizon will not only improve the performance of your machines but also give you a competitive edge in a rapidly changing market.

As someone who has been closely following these developments, I can confidently say that investing in the latest ball screw technology will pay dividends in terms of efficiency, reliability, and overall performance. The future is bright for ball screws, and I’m excited to see how these innovations will shape the industries of tomorrow.

By staying ahead of these trends, you can ensure that your operations remain at the cutting edge, delivering the precision and quality that your customers expect.