Ball screws are precision mechanical components that transform rotary motion into linear motion with exceptional efficiency and minimal friction. They’re a cornerstone of modern motion control systems, used in everything from industrial automation to aerospace. Let’s break down the ten main types of ball screws and their specific functions.

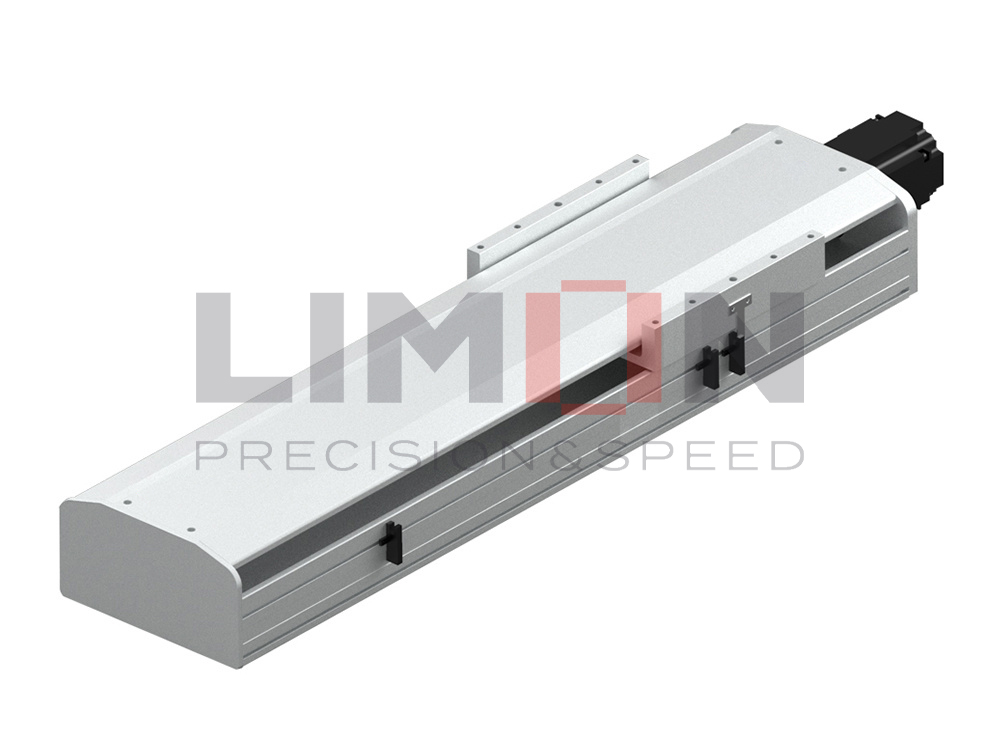

1. Cylindrical Ball Screw

Function: The most common type, featuring a cylindrical nut and threaded shaft.

Applications: Ideal for machinery, robotics, and automated systems that demand high efficiency and precision.

2. Miniature Ball Screw

Function: Compact and efficient, this miniature ball screw is engineered for small-space installations.

Applications: Common in medical devices, precision robotics, and micro-mechanics.

3. Angular Contact Ball Screw

Function: Designed with angular contact ball bearings to support higher axial loads and maintain stability at high speeds.

Applications: Perfect for CNC machines, high-speed actuators, and industrial motion platforms.

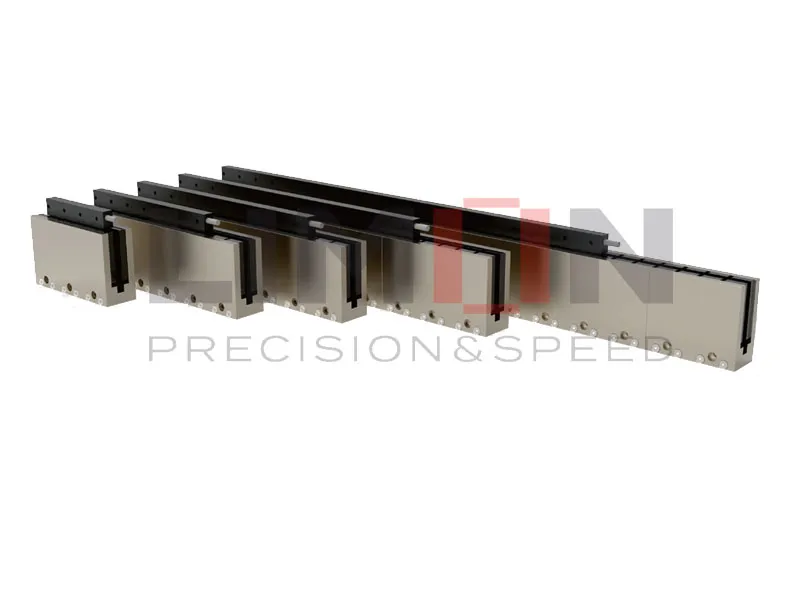

4. Double Nut Ball Screw

Function: Utilizes two nuts to effectively reduce backlash and enhance positional accuracy.

Applications: Frequently used in aerospace systems, precision measuring instruments, and automated testing equipment.

5. Rolled Ball Screw

Function: Manufactured via thread rolling, offering a cost-effective ball screw solution with good efficiency.

Applications: Suitable for general industrial machinery where ultra-precision is not critical.

6. Ground Ball Screw

Function: Precision-ground for high-performance applications, offering superior surface finish and accuracy.

Applications: Trusted in medical equipment, semiconductor machinery, and aerospace-grade motion systems.

7. Self-Lubricating Ball Screw

Function: Integrated lubrication system delivers continuous, maintenance-free operation.

Applications: Ideal for cleanroom environments, food-grade machinery, and maintenance-challenged installations.

8. High-Load Ball Screw

Function: Built with larger ball bearings and robust construction to handle intense mechanical loads.

Applications: Used in press machines, heavy-duty CNC tools, and industrial-grade actuators.

9. Preloaded Ball Screw

Function: Features an internal preload to eliminate axial clearance, delivering enhanced stability and responsiveness.

Applications: A go-to for robotic arms, gantry systems, and precision servo drives.

10. Backlash-Free Ball Screw

Function: Specially engineered to remove or minimize backlash, ensuring flawless directional changes.

Applications: Critical in semiconductor manufacturing, metrology tools, and nano-positioning systems.

Final Takeaway: Choosing the Right Ball Screw Matters

Each type of ball screw offers unique performance characteristics tailored to specific industrial needs—whether that’s ultra-precise motion, load endurance, compact design, or low maintenance.

When selecting a ball screw for your application, consider:

-

Precision requirements

-

Load and speed

-

Environmental conditions

-

Space and maintenance constraints

Need help deciding which ball screw fits your system? Let’s talk motion mechanics and build a smarter solution together.