Unreliable positioning in machinery leads to wasted resources and costly downtime. Without stepper motors, precision control suffers. The solution: understanding their principles and applications.

Stepper motors are electromechanical devices that convert electrical pulses into discrete mechanical movements, offering precise control over position and speed without needing complex feedback systems.

Keep reading to discover the fundamentals and practical uses of stepper motors.

Stepper Motor Basics

Stepper motors are a category of brushless DC motors that move in fixed angular increments, also known as steps. Each step corresponds to a specific electrical pulse received by the motor. Unlike conventional motors that rotate continuously, stepper motors move incrementally, allowing precise control over angular position without requiring sensors or encoders in open-loop systems.

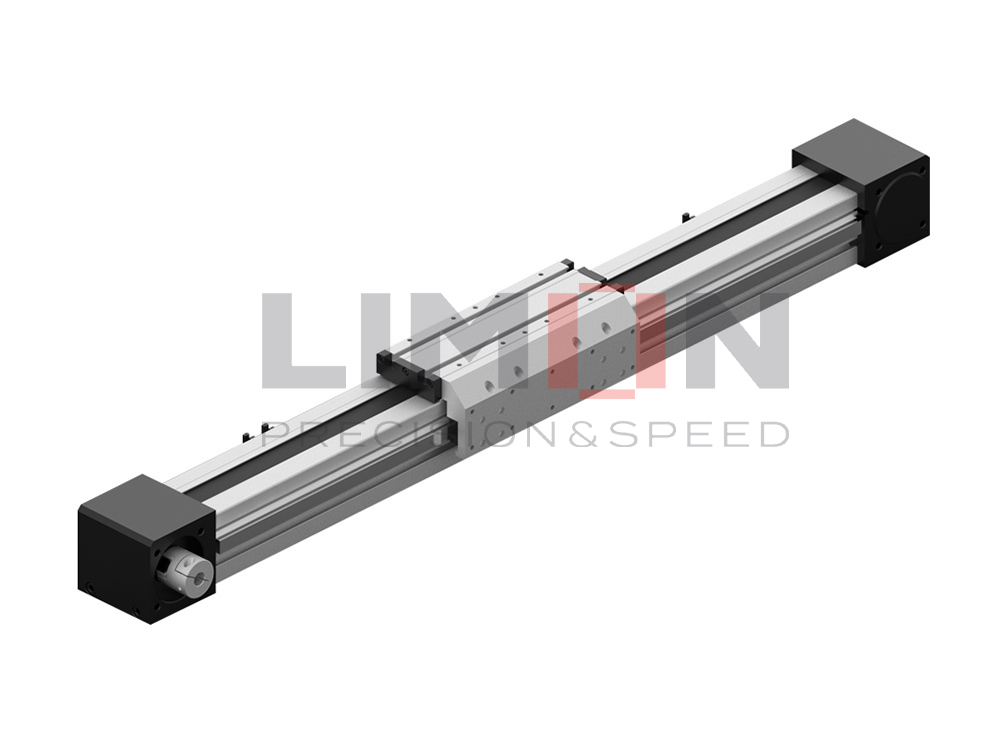

This unique stepping capability makes them popular in industries that demand precision, such as robotics, 3D printing, medical devices, and CNC machinery. Stepper motors operate reliably at low speeds with full torque, making them superior in tasks where precision trumps raw speed. However, unlike servo motors, they may lose synchronization at very high speeds or under heavy loads if not properly managed.

Stepper Motor Working Principles

The working principle of stepper motors is based on electromagnetic induction and sequential energizing of stator windings. The stator contains multiple coils arranged in phases. When a phase is energized, it produces a magnetic field that attracts the rotor teeth. By energizing the phases in a specific sequence, the rotor moves step by step.

The size of each step depends on the motor’s design, typically ranging from 0.9° to 1.8° per step. Stepper motors can operate in full-step, half-step, or micro-stepping modes. Micro-stepping divides each step into smaller increments, increasing resolution and smoothness while reducing vibrations.

This precise, incremental movement enables exact positioning, which is why stepper motors are frequently used in open-loop control systems where feedback devices are not necessary.

Stepper Motor Types and Construction

Stepper motors come in several designs, each optimized for specific applications. The three primary types are:

-

Permanent Magnet (PM) Stepper Motors:

Use permanent magnets in the rotor. They provide low torque but are simple and cost-effective. -

Variable Reluctance (VR) Stepper Motors:

Use a soft iron rotor with no permanent magnets. They are fast and precise but generate lower torque. -

Hybrid Stepper Motors:

Combine features of PM and VR motors. They are the most widely used type, offering high torque, precision, and reliability.

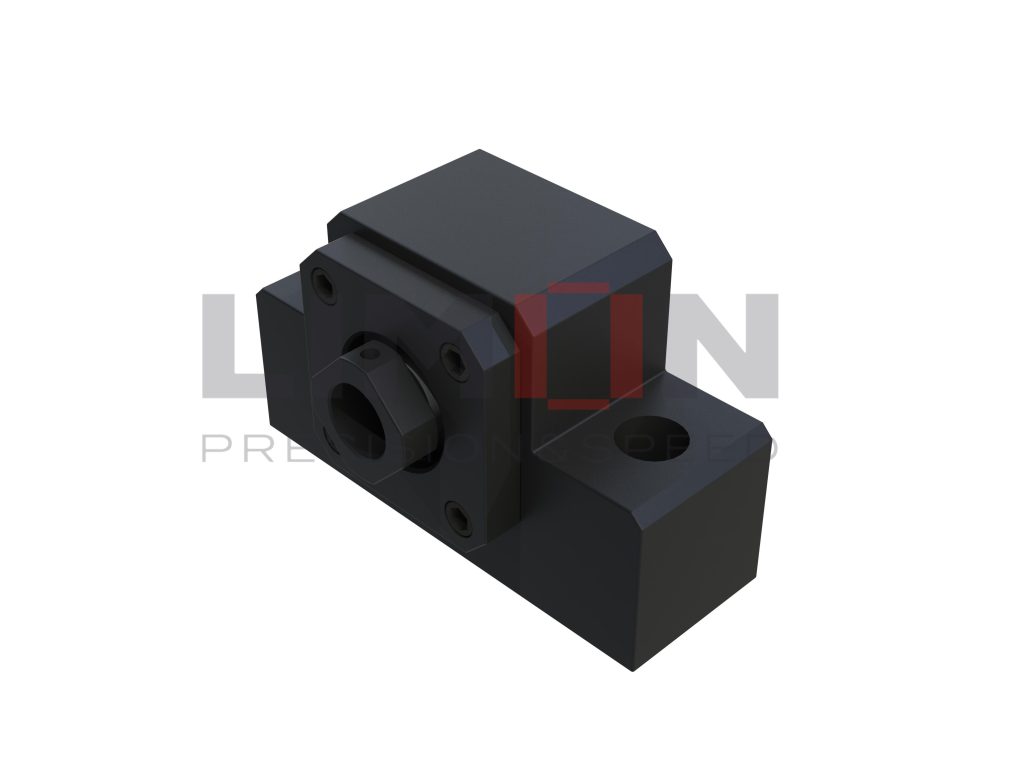

In terms of construction, stepper motors consist of a rotor (with teeth or magnets), a stator with multiple windings, bearings, and a housing. Hybrid designs often include detent torque, holding the rotor in position even when not powered, making them ideal for applications like printers and machine tools.

Stepper Motor Control

Control of stepper motors involves sending electrical pulses to the motor driver, which in turn energizes the motor’s windings in the correct sequence. The frequency of these pulses determines the motor’s speed, while the number of pulses defines the angle of rotation.

There are several control modes:

-

Wave Drive (One-Phase On): Only one winding energized at a time. Simple but low torque.

-

Full Step (Two-Phase On): Two windings energized, producing higher torque.

-

Half Step: Alternates between one and two phases energized. Provides smoother motion.

-

Micro-Stepping: Uses sine-wave current control for ultra-smooth motion and reduced vibrations.

Control systems can be open-loop (simpler and cheaper) or closed-loop (using feedback to prevent missed steps). Modern stepper drivers often integrate microprocessor-based controllers for advanced functionality.

Stepper Motor Driving Techniques

Driving techniques are essential to optimize motor performance. Common methods include:

-

Constant Voltage Drive: Simplest method but limited by winding inductance.

-

Constant Current Chopper Drive: Widely used, maintains constant current to optimize torque and efficiency.

-

L/R Drive: Basic resistor-capacitor networks to control current decay.

-

Bipolar vs Unipolar Drive:

-

Unipolar motors are easier to control but less powerful.

-

Bipolar motors deliver higher torque but require more complex driver circuits.

-

Advanced drivers also employ features like current decay modes (slow, fast, mixed) to enhance speed, precision, and torque. This makes stepper motors adaptable to a wide range of applications, from small electronics to industrial automation.

Stepper Motors Advantages and Disadvantages

Advantages:

-

High precision and repeatability.

-

Simple open-loop control (no feedback required).

-

Good low-speed torque.

-

Affordable and robust.

Disadvantages:

-

Limited high-speed capability.

-

Resonance and vibration at certain speeds.

-

Lower efficiency compared to servo motors.

-

Possible step loss in open-loop mode under heavy load.

These pros and cons must be carefully considered when selecting stepper motors for applications requiring precision versus high speed and torque.

Stepper Motor Uses and Applications

Stepper motors are used in a wide variety of industries due to their accuracy, cost-effectiveness, and versatility. Some examples include:

-

Printers and Scanners: Accurate paper feed and printhead positioning.

-

CNC Machines: Precise cutting and milling operations.

-

3D Printers: Smooth layer-by-layer movement of print heads.

-

Robotics: Position control in robotic arms and actuators.

-

Medical Equipment: Imaging systems and fluid pumps.

-

Textile Machinery: Precise fabric feed mechanisms.

-

Aerospace: Satellite positioning and instrumentation.

In modern automation, stepper motors remain the preferred choice for tasks requiring moderate torque, precision positioning, and cost-efficiency.

Conclusion

Stepper motors deliver reliable precision and flexibility, powering industries from robotics to medical devices effectively.For further questions please contact [email protected]