Understanding Ball Screws in Automation

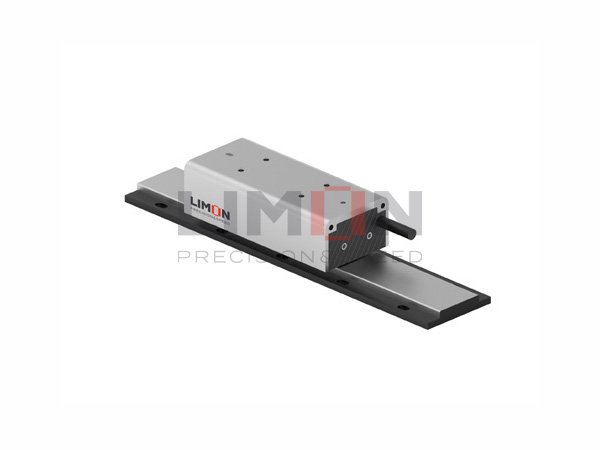

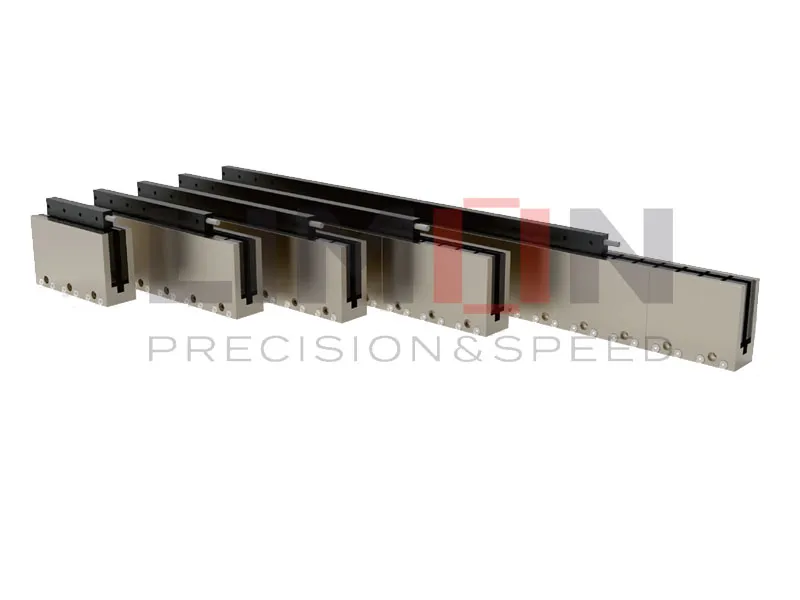

Ball screws convert rotational motion into linear motion with minimal friction, vital in CNC machinery and robotics. Unlike lead screws, they use ball bearings for smoother operation.

Why Ball Screws Matter

High Precision: Ball screws offer micrometer-level accuracy, crucial in aerospace, automotive, and medical device manufacturing.

Reduced Friction: Their rolling action minimizes friction, extending lifespan and reducing maintenance.

Heavy-Duty Capability: Ball screws handle higher loads and provide greater rigidity, perfect for demanding applications.

Quiet Operation: Smooth rolling leads to quieter environments, ideal for noise-sensitive settings.

Integration Tips

Design Considerations: Collaborate with engineers to match ball screws to specific needs.

Material Selection: Choose materials based on operational demands and load requirements.

Lubrication and Maintenance: Implement automated lubrication systems and regular maintenance schedules.

Customization and Upgrades: Explore customized solutions for tailored performance improvements.

Real-World Success Stories

Automotive Enhancement: A 20% increase in production speed and 15% defect rate reduction achieved by integrating high-precision ball screws into assembly line robots.

CNC Machining: Improved accuracy and significant scrap material reduction after upgrading equipment with ball screws.

Ball screws are pivotal in modern industrial automation, offering unmatched efficiency, precision, and reliability. Whether upgrading existing systems or designing new solutions, they promise high returns in productivity and quality. Explore their potential to transform your operations by reaching out to experienced suppliers and engineers.