Ball screws are integral to achieving precision and efficiency in mechanical systems. The correct installation and assembly of ball screws is essential for ensuring their peak performance and longevity, particularly in sophisticated applications like CNC machines and linear actuators.

Installation Steps

Preparing Components:It’s crucial to thoroughly inspect all components, including ball screws, their nuts, and bearings. This initial step guarantees that each part is in pristine condition, free from damage, and ready for optimal functionality.

Aligning Screw and Nut:Precise alignment of ball screws with their nuts is fundamental. Any misalignment can cause premature wear and diminish efficiency, a critical factor in the comparison of ball screws vs lead screws.

Securing Ball Screws:Properly securing ball screws within the assembly is vital. They must be well-supported and precisely aligned with the drive system to ensure smooth and efficient operation.

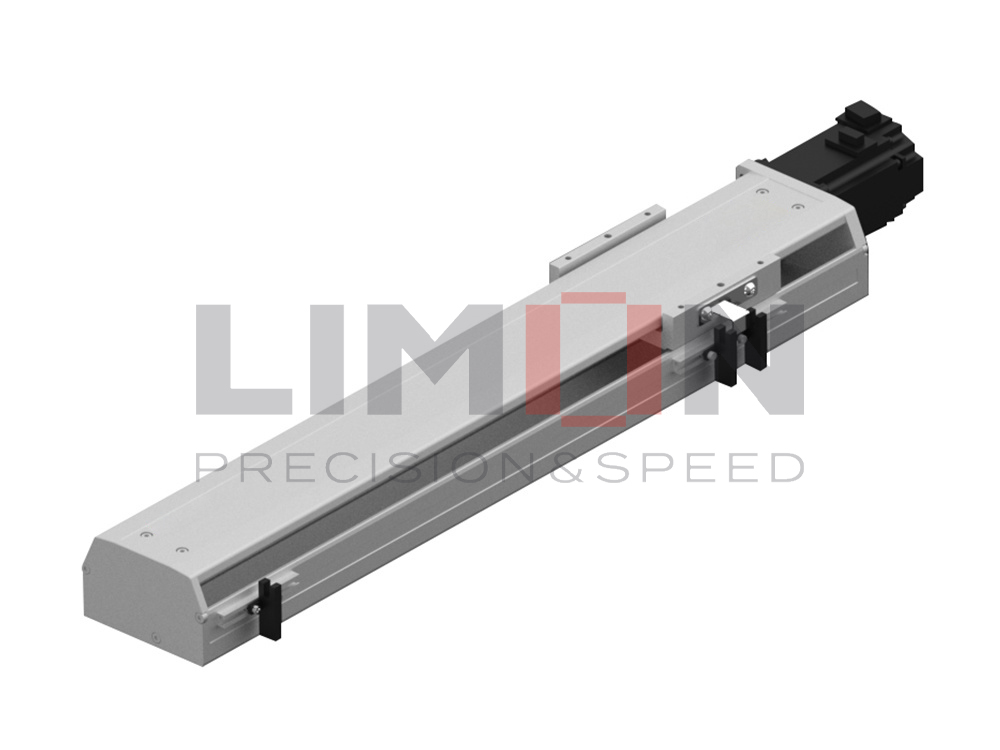

_15.jpg)

Assembly Considerations

Lubrication:Effective lubrication of ball screws and their bearings is essential. Proper lubrication minimizes friction and wear, enhancing both the performance and the lifespan of the ball screw system.

Backlash Adjustment:For high-precision applications, such as those involving ball screw linear actuators, adjusting backlash is critical. This fine-tuning ensures accurate and smooth motion.

Proper installation and assembly are more than just mechanical tasks; they are critical for the efficiency, precision, and durability of ball screws. Whether used in ball screw CNC systems, linear actuators, or other applications, attention to detail in alignment, lubrication, and adjustments significantly impacts the performance and longevity of ball screws. While ball screw repair services exist, preventative maintenance through correct installation and assembly is always preferable.