-

What exactly is the ball screws used for?

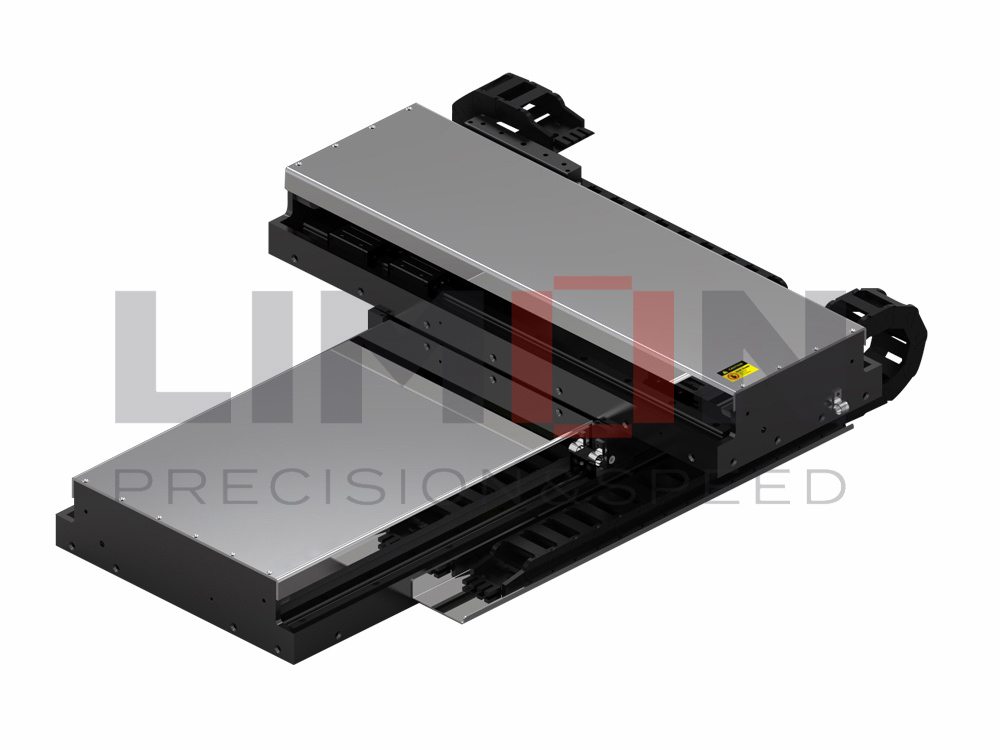

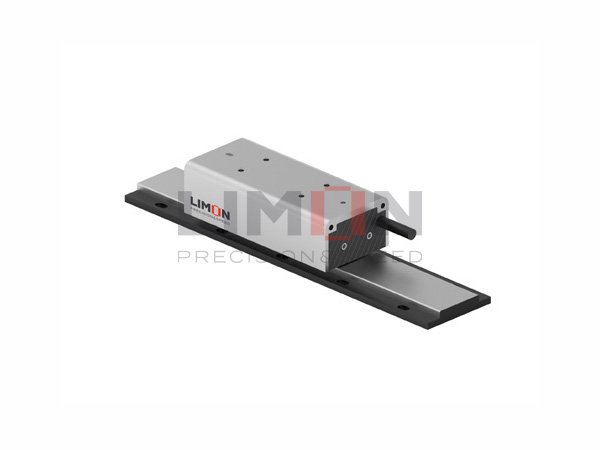

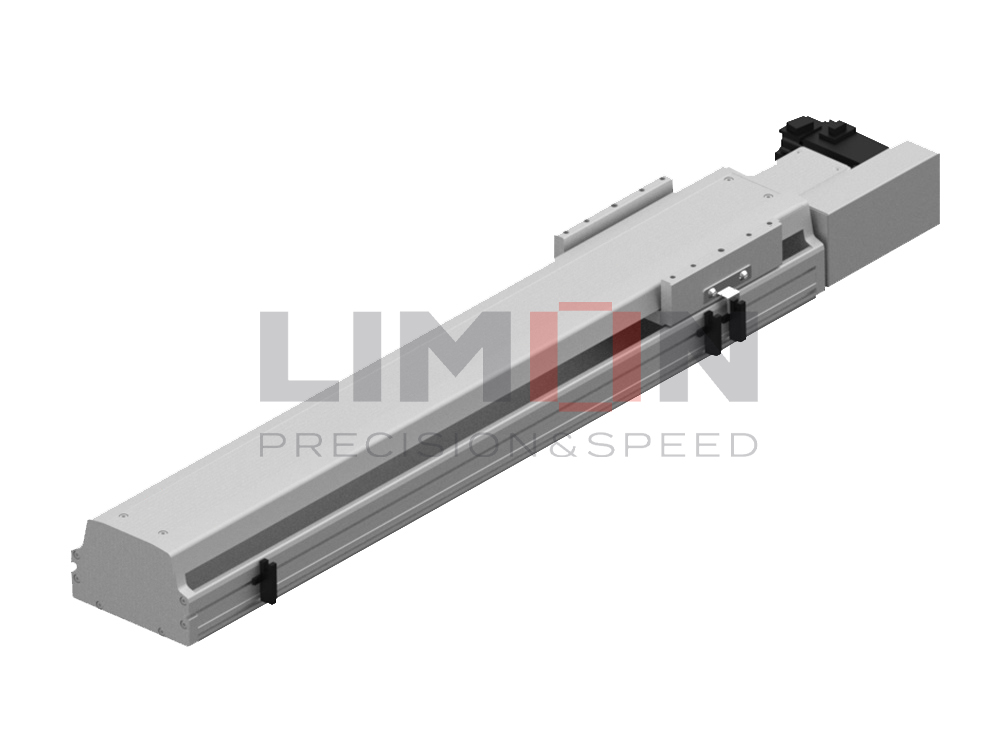

The main function of screw rod is to convert rotary motion into linear motion, or convert linear motion into rotary motion. The ball screw consists of three parts: screw, nut and ball. We can see its exquisite structure in the ball screw 3d model drawings. It can convert rotary motion into linear motion, which is the further development of ball screw. Because it has very small friction resistance, ball screw is now widely used in various precision instruments, so we often have to face the problem of screw selection. In addition to analyzing its application through ball screw 3d model drawings, what knowledge do we need to know?

- The use of ball screw:

In order to adapt to various uses, screw rod provides many standardized products, which are now widely used in machine tools. We can often see many ball screw 3d model, which are based on the technology accumulated for many years. The materials, heat treatment, manufacturing and inspection processes are managed through strict quality inspection. Therefore, the ball screw in the screw rod has high reliability to some extent. Among them, the end cap type ball screw is used in precision tool machines, electronic machinery and high-speed machinery, while the high-speed ball screw is used in aerospace industry and other antenna actuators. The use of screw rod is becoming more and more extensive.

- The characteristics of ball screw:

First, its high precision is guaranteed. Ball screw rod is generally produced by multiple processes with the highest level of mechanical equipment in the world. We can see its ingenious design from the ball screw 3d model. Especially in the process of assembly and inspection, it is made through strict control, and the temperature and humidity are strictly controlled. In the production process, its perfect quality management system makes it deeply loved by consumers. In addition, it is designed without side clearance and has very high rigidity, so the torque is very small when starting, and there will be no sliding and other phenomena. In this way, it can ensure the possibility of accurate micro feeding.

Then how to select ball screw? These several parameters must be known:

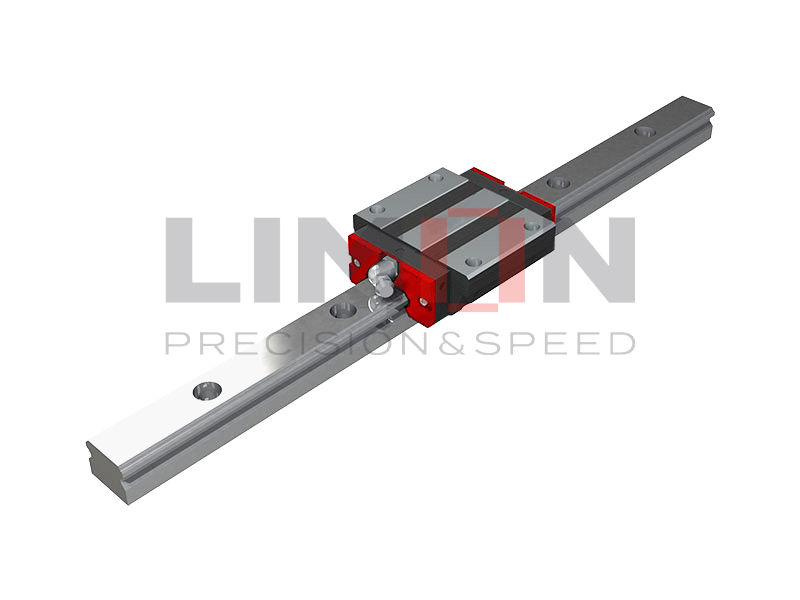

- Nominal diameter

That is, the outer diameter of the lead screw. The common standards are 12, 14, 16, 20, 25, 32, 40, 50, 63, 80 The nominal diameter is directly proportional to the load. The larger the diameter, the greater the load. For detailed values, please refer to the ball screw 3d model or sample of the screw rod of the manufacturer. Introduction: the diameter shall be 16~63 as far as possible

- Lead

It is also called pitch, that is, the interval of nut linear movement every time the screw rotates. The common leads are 2, 4, 6, 8, 10, 16 The lead is related to the linear speed. When the input speed is constant, the larger the lead, the faster the speed. Introduction: Lead shall be 5 and 10 as far as possible.

- Nut method

There are many nut methods on the product samples or ball screw 3d model of various manufacturers. The first few letters in the general type indicate the nut method. According to the flange method, there are about circular flange, single chamfered flange, double chamfered flange and no flange. There are single nut and double nut according to the length of nut. Introduction: double nuts shall be selected for frequent action and high-precision maintenance occasions.

- Accuracy

It is indicated by c0~c10 or detailed values that, generally speaking, C7 (arbitrary positioning error within 300 strokes ± 0.05) or below is selected for general-purpose machinery or common CNC machinery, C5 (± 0.018) or above and C3 (± 0.008) or below is selected for high-precision CNC machinery, and C3 or above is selected for optical or detection machinery.

- Preloading

For preloading, users do not need to know the detailed preloading force and preloading method, but only need to select the preloading grade according to the manufacturer’s sample or ball screw 3d model. The higher the level, the tighter the nut fits with the screw, and the lower the level, the looser. The principle to be followed is: under the conditions of large diameter, double nuts, high precision and large driving torque, the preloading grade can be selected higher, otherwise the preloading grade can be selected lower.