Linear rail and ball screw are very common products in linear motion systems, so how does linear rails and ball screw work? What are the difference between them? Let’s unveil Linear rail and ball screw together!

Linear rails and ball screw – Application:

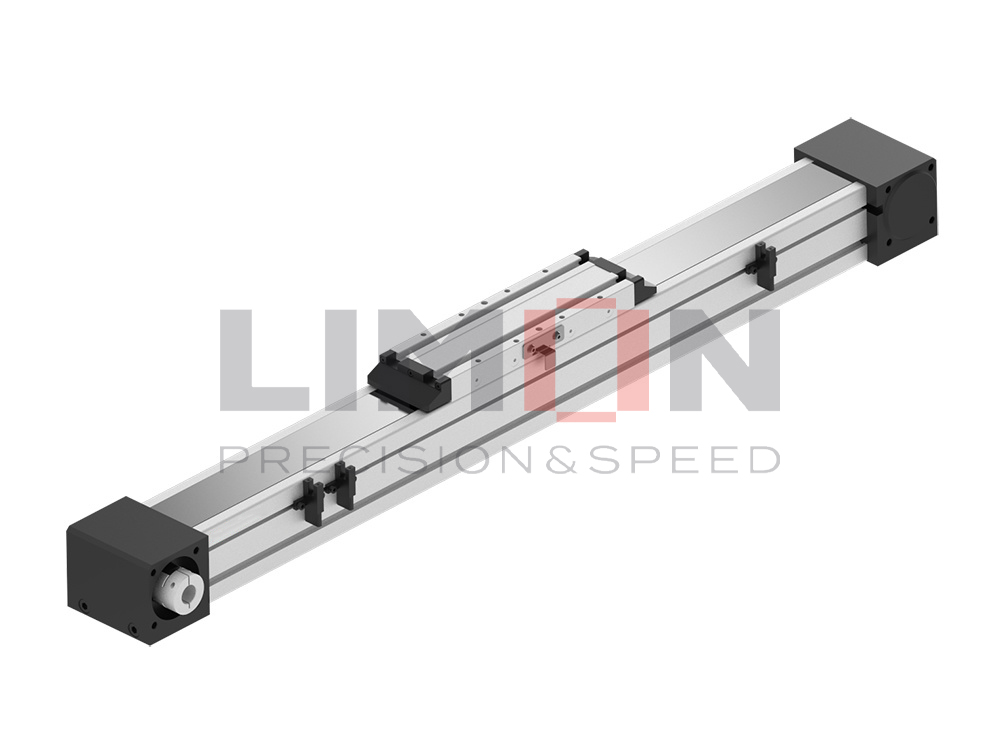

- Linear rail:

Also known as line rail, slide rail, linear guide rail and linear slide rail, is used for linear reciprocating motion, and can bear a certain torque, and can realize high-precision linear motion under high load.

Linear rails are widely used, but there are many kinds. Square four row high ball guideways are used for some large machine tools and equipment, such as surface grinder, slicer, wire cutting, etc; Because of different working conditions, the linear guide rail is also different.

It is most suitable for precision measuring instruments, semiconductor manufacturing and inspection equipment, non-standard automatic mechanical equipment and other important applications of precision linear motion. It is also very important to select the correct guide rail for different equipment needs.

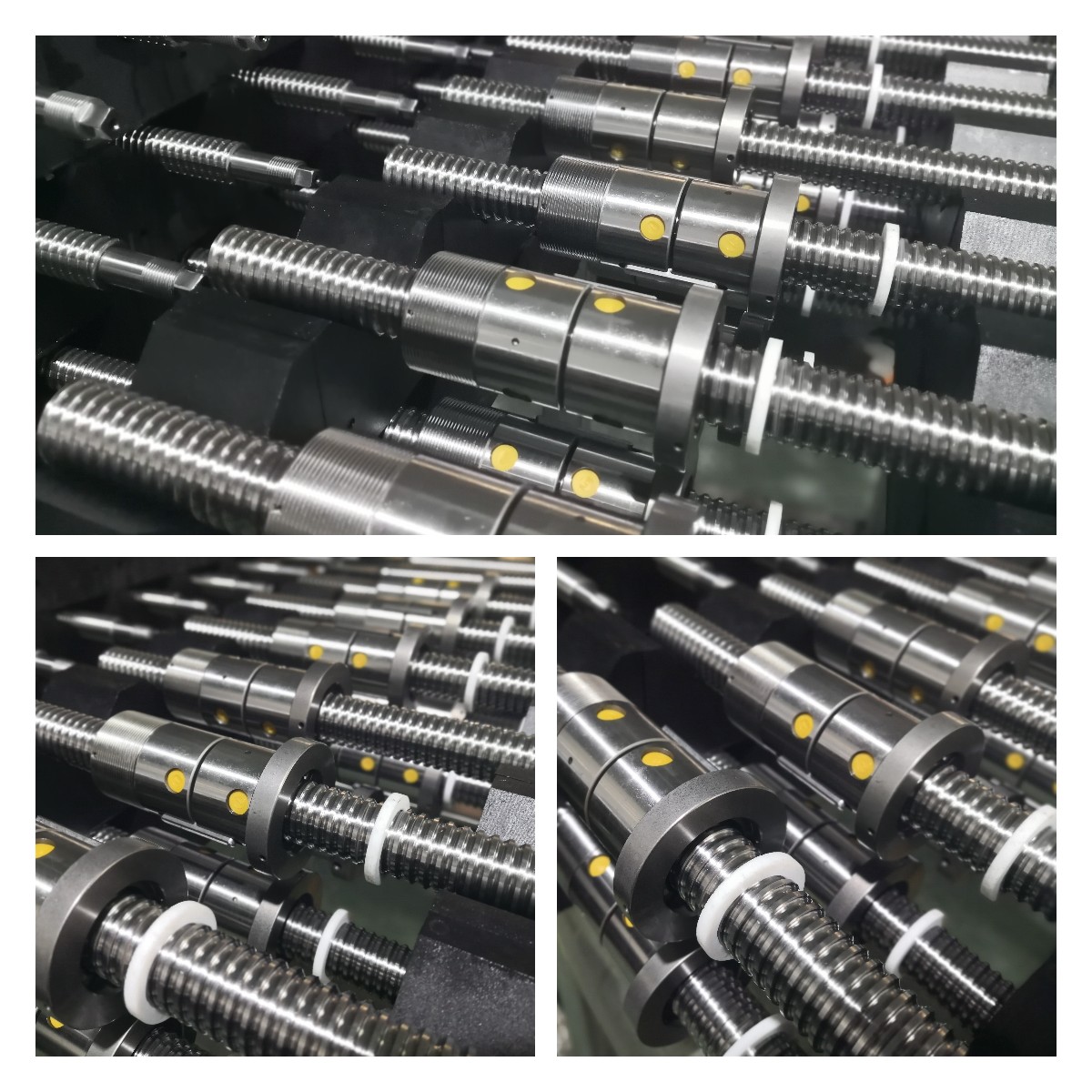

- Ball screw:

As a kind of high-precision transmission component, is widely used in CNC machine tools, electronic precision mechanical feeding mechanism of automatic machining centers, servo manipulators, industrial assembly robots, semiconductor production equipment, food processing and packaging, medical equipment and other fields.

Ball screw is the most commonly used transmission element in tool machinery and precision machinery. It is composed of screw, nut, steel ball, prepress, reverser and dustproof device. Its main function is to convert rotary motion into linear motion or torque into axial repeated force. At the same time, it has the characteristics of high precision, reversibility and high efficiency.

It is mainly used for some machine tools, large equipment, engraving machinery, etc. it is very convenient to convert rotating motion into linear motion, which is very convenient to use, so as to reduce the wear of the whole equipment in terms of rotation.

Linear guide rail and ball screw are both linear transmission equipment, but their working principle, requirements and application range are different, but their performance in linear transmission is very excellent.

Linear rails and ball screw – Characteristics:

- Linear rails:

1. High positioning accuracy

When the linear guide is used as the linear guide, because the friction mode of the linear guide is rolling friction, not only the friction coefficient is reduced to 1/50 of the sliding guide, but also the difference between the dynamic friction and the static friction becomes very small. Therefore, when the table moves, there will be no sliding phenomenon, and the ultra-high precision (UM) level can be reached.

2. Less abrasion can maintain accuracy for a long time

The traditional sliding guide inevitably causes poor motion accuracy of the platform due to the oil film countercurrent effect, and the insufficient lubrication during the movement leads to the wear of the contact surface of the running track, which seriously affects the accuracy. However, the wear of the rolling guide is very small, so the machine can maintain the accuracy for a long time.

3. Use high-speed movement and greatly reduce the driving horsepower required by the machine

Because the friction force of the linear guide rail is very small when it moves, it only needs a small power to make the bed table run. Especially when the working mode of the bed table is regular round-trip movement, it can significantly reduce the point force loss of the machine table, and the heat generated by its friction is small, so it is suitable for high-speed operation.

4. It can bear up, down, left and right loads at the same time

Due to the special bundle structure design of the linear guide rail, it can bear the load in the up, down, left and right directions at the same time. The lateral load that the sliding guide can bear in the direction parallel to the contact surface is light, which is easy to cause poor operation accuracy of the machine.

5. Easy assembly and interchangeability

During assembly, as long as the assembly surface of the guide rail on the machine table is milled or ground, and the guide rail and sliding block are fixed on the machine table according to the recommended steps, which can not only pay attention to the high precision during processing, but also the traditional sliding guidance, the running track must be chipped, which is both time-consuming and time-consuming. Once the machine table precision is poor, it must be chipped once. The linear guide rail is interchangeable, and the slider cargo guide rail can be replaced to the linear guide rail group, The machine can regain high-precision guidance.

6. Simple lubrication structure

If the sliding guide is not lubricated enough, it will cause direct friction loss of the contact surface metal. However, it is not easy for the sliding guide to be lubricated enough. It is necessary to drill a hole at the appropriate position of the bed for oil supply. The linear guide rail has been installed at the oil nozzle, so it can directly inject grease with an oil gun. It can also be replaced with a special oil pipe joint to link the oil supply pipe for automatic oil supply machine lubrication.

- Ball screw:

1. Guarantee of high precision

Ball screw pairs are continuously produced with the world’s highest level mechanical equipment made in Japan. In particular, in terms of the factory environment for grinding, assembly and inspection processes, the temperature and humidity are strictly controlled. Due to the perfect quality management system, the accuracy is fully guaranteed

2. No side clearance, high rigidity

The ball screw pair can be pre pressed, because the pre pressure can make the axial clearance reach a negative value, and then get a higher rigidity (the ball screw can increase the rigidity of the screw mother part due to the repulsion of the ball when it is actually used in mechanical devices)

3. High speed feed possible

The ball screw can realize high-speed feed (movement) because of its high movement efficiency and low heating.

s.jpg)