Linear guides are indispensable components in machinery, orchestrating the seamless linear motion that underpins precision in countless applications. Understanding how linear guides work involves delving into their intricate structure and the synergy of key elements.

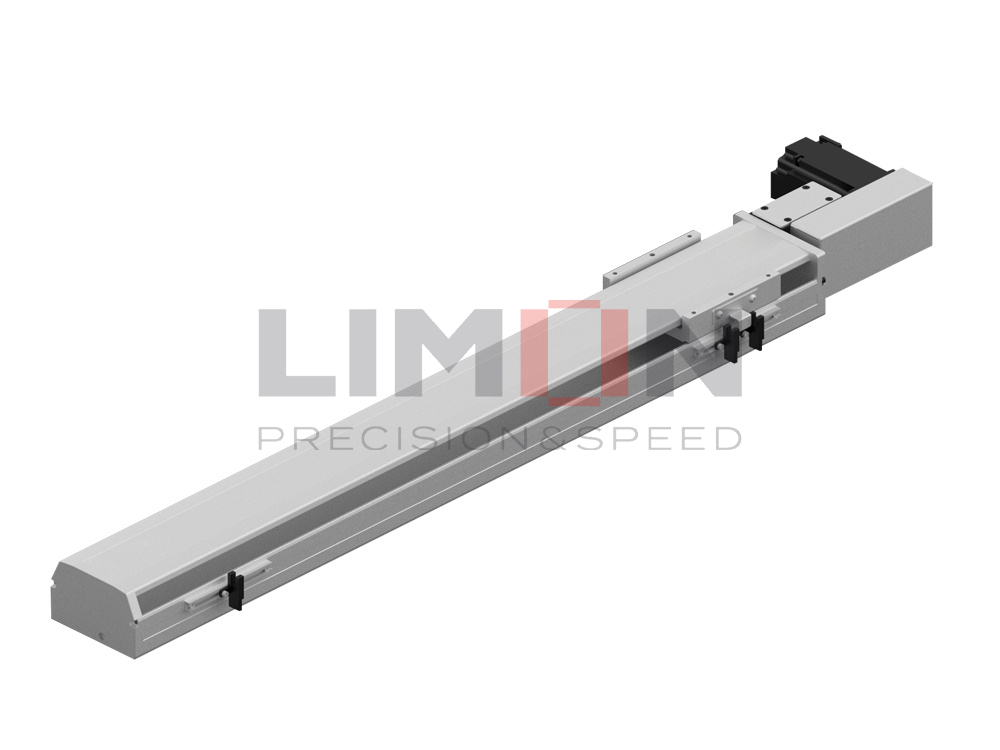

The Core Mechanics: At the heart of linear guides is the aluminum linear guide rail, forming the sturdy foundation upon which the system operates. A CNC linear guide rail enhances the precision of the motion, making it ideal for applications demanding utmost accuracy. In heavy-duty scenarios, heavy-duty linear guide rails step in to bear substantial loads without compromising on performance.

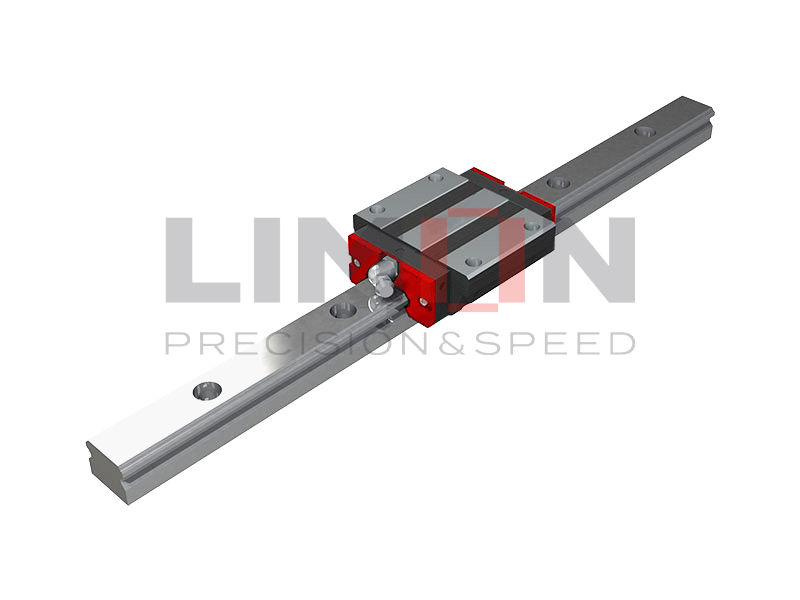

Bearing the Load: Linear guide bearings are pivotal in the operation, strategically positioned along the guide rail. These bearings facilitate frictionless movement, ensuring a smooth glide. The linear guide block, or carriage, encapsulates these bearings and connects to the moving element, a crucial link that dictates the controlled trajectory of the motion.

Synergy of Rails and Carriages: Linear guide rail and carriage configurations vary based on application needs. Linear guide rail systems, consisting of precisely matched rails and carriages, ensure optimal performance. The interplay of linear guide rails and bearings is key to supporting and guiding the linear motion seamlessly.

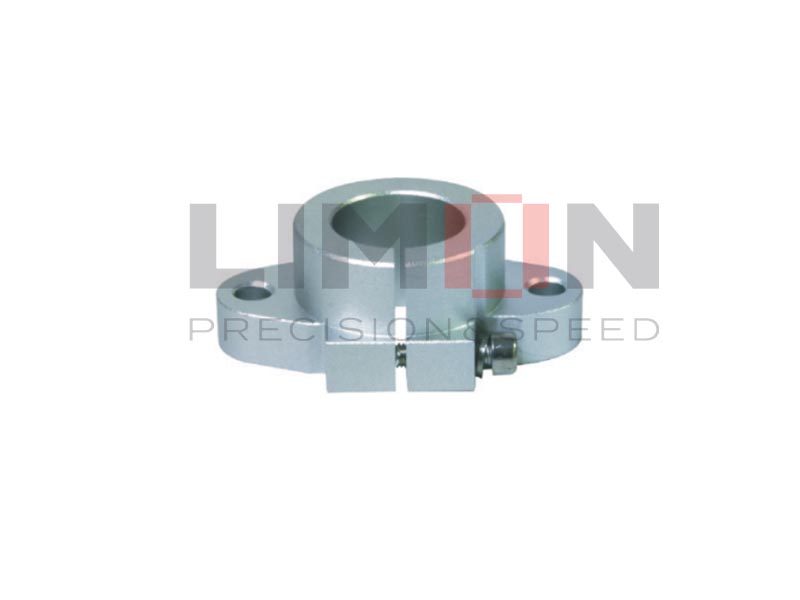

Critical Components: The linear guide shaft contributes to the system’s stability, enhancing the overall rigidity. Linear guide sliders, integral for smooth motion, complement the system, ensuring precision in diverse applications. These components collectively form intricate linear guide systems, playing a pivotal role in achieving consistent and reliable motion.

Precision in Practice: In comparing linear guide vs. box way systems, the former stands out for applications demanding precision and dynamic performance. Linear guides and rails, be they square linear guides or slide linear guides, are designed to deliver accuracy, making them indispensable in applications where precision is paramount.

Customization and Adaptability: Linear guideways, with their diverse configurations, allow for customization to suit specific requirements. Whether it’s a linear guideway carriage, a roller-type linear guideway, or a square linear guide, the adaptability of these systems makes them versatile for a multitude of applications.

Navigating Choices: Understanding the nuances of linear guideways 3D models aids in visualizing their application in real-world scenarios. When seeking optimal performance, discerning linear guideway manufacturers and exploring linear guideway rail options become crucial considerations.

In essence, the orchestration of motion by linear guides is a symphony of meticulously designed components. From the precision linear guide to the adaptability of slide linear guides, these systems underscore the importance of engineering excellence. Embracing the intricacies of linear guides ensures that your machinery moves with the precision and reliability demanded by modern industries.

s.jpg)