How about linear guideways selection?

How to do linear guideways selection – preload?

How to do LIMON linear guideways selection?

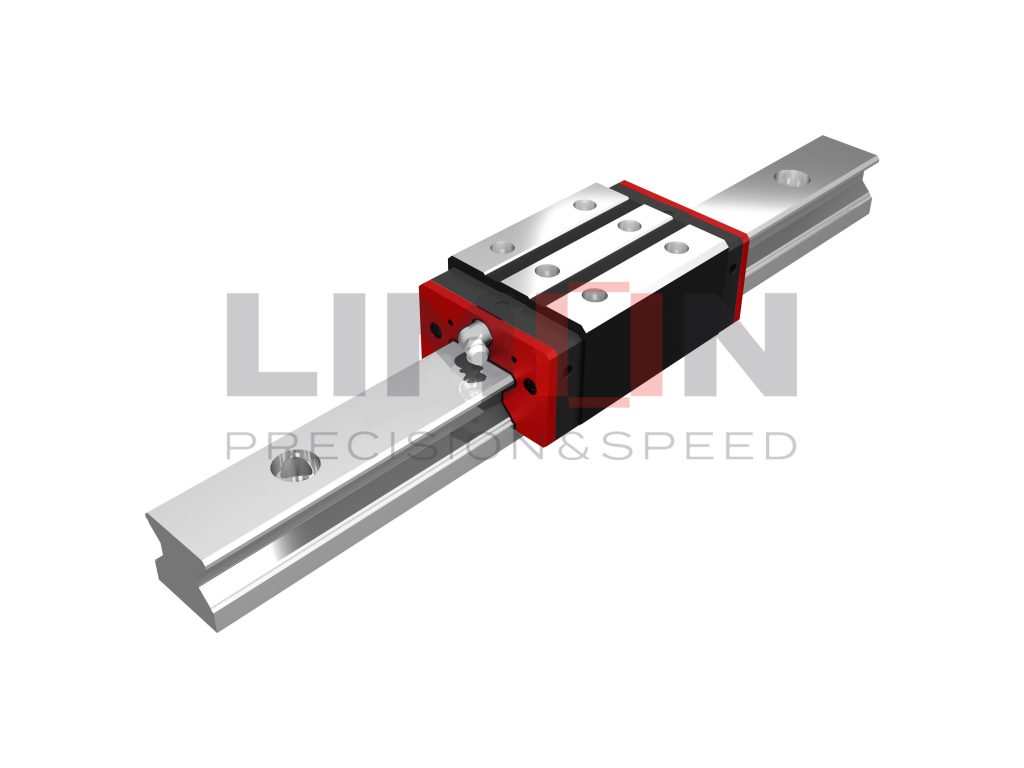

What is linear motion guides and how linear guideways selection?Linear Guides are a block and rail system that helps support the motion of an application.There are two parts to the Linear Guide System: the Linear Block and the Linear Rail. The linear block moves along the linear rail along the plane the rail is positioned for. The block moves forward and backward along the straight linear rail. Linear blocks connect to the moving components by mounting to the block to support the motion for the specified component. The motion is created along the rail through recirculating ball bearings within the block that is contacted on the rail.

How about linear guideways selection?

When choosing a recirculating linear guide, there are several criteria that need to be specified, including size, preload and accuracy. And although the term “accuracy” is often used in a generic sense, when referring to recirculating ball or roller guides, it designates five characteristics:

1.Height tolerance of the rail and block assembly

2.Permissible difference in height between multiple blocks on the same rail

3.Width tolerance of the rail and block assembly

4.Permissible difference in width between multiple blocks on same rail

5.Parallelism between reference edges of the rail and the block

How to do linear guideways selection – preload?

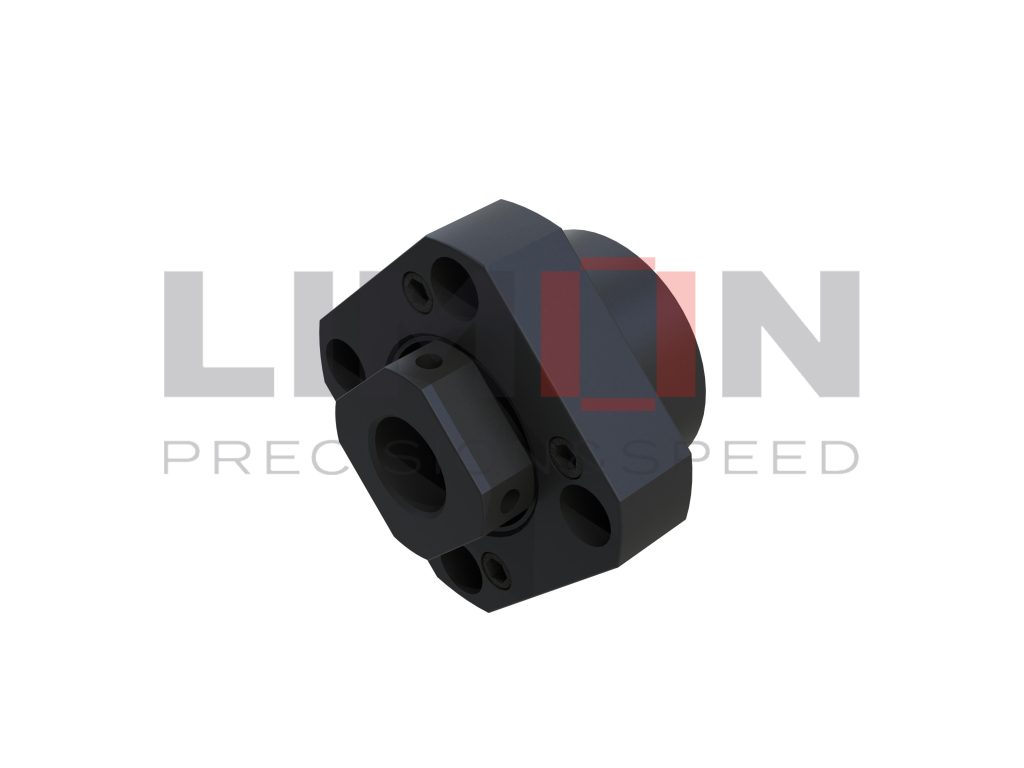

When choosing a recirculating linear guide, one of the key criteria in the specification is preload. Linear guide preload eliminates the clearance between the bearing block and the rail, which increases rigidity and reduces deflection when external loads are applied.

To achieve preload, manufacturers use balls (or rollers, in the case of roller bearings) whose diameter is slightly larger than the distance between the raceways of the block and the rail. The preload of a linear bearing block is given as the percentage of dynamic load capacity that is induced on the bearing, with common preload amounts being 2, 5, and 8 percent. For example, a bearing block with a dynamic load capacity of 30,000 N and a preload of 5 percent would experience a preload force of 1500 N. For roller bearing guides, which are typically used for extremely high loads and/or minimal deflection, preload amounts up to 13 percent are available.

How to do LIMON linear guideways selection?

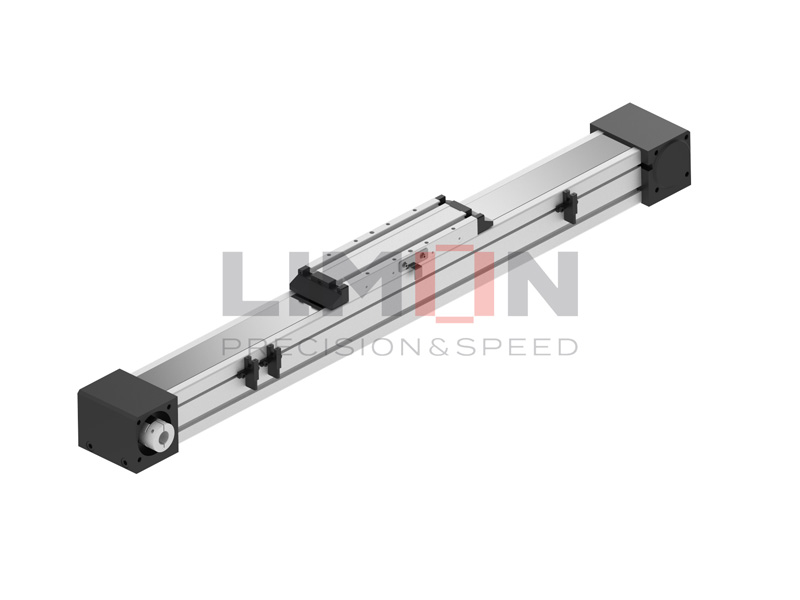

HH series-Grinding, milling and drilling machine, lathe, machine center.

EH series–Automatic equipment, high speed transfer device, semiconductor equipment, wood cutting machine, precision measure equipment.

QE/QH series-precision measure equipment, semiconductor equipment, Automatic equipment, laser marking machine, can be widely applied in high-tech industry required high speed, low noise, low dust generation.

RH series-CNC machining centres,heavy duty cutting machines, CNC grinding machines, injection moulding machines, electric discharge machines, wire cutting machines, plano millers.

These are the informations for linear guideways selection.The correct selection of linear motion products is essential for design longevity. It is important to consider all of the above aspects before choosing the type of rolling element (ball, roller or plain) and then specifying the final product. Whilst cost will always have a major influence, product suitability is key.