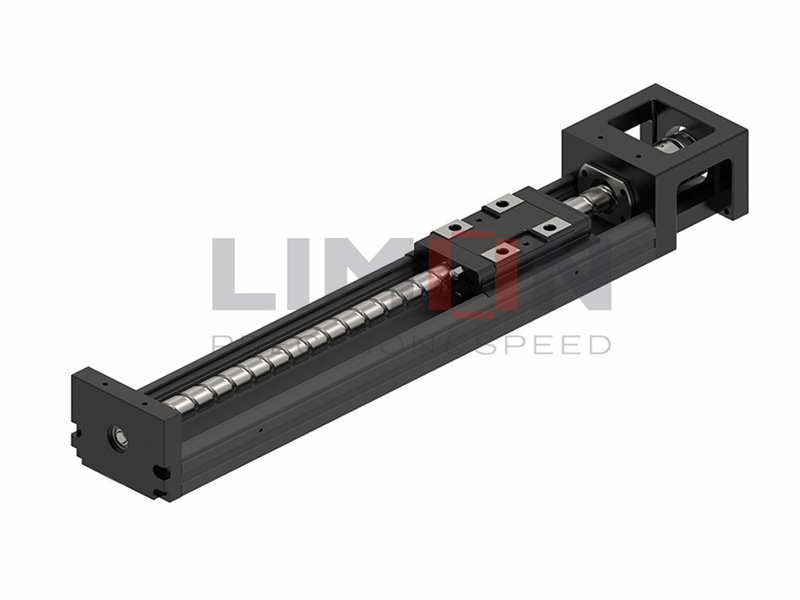

Components of Ball Screws:

1. Screw Shaft: The central component of a ball screw is the screw shaft, which features a helical groove along its length. This groove serves as a track for the movement of ball bearings, allowing them to circulate smoothly during operation.

2. Ball Nut: The ball nut is threaded onto the screw shaft and contains recirculating ball bearings. This nut is responsible for transforming the rotational motion of the screw shaft into linear motion by guiding the ball bearings along the helical path.

3. Ball Bearings: Small ball bearings within the ball nut are the key to the ball screw’s functionality. These bearings move within the helical groove, effectively reducing friction and ensuring a seamless transformation of motion.

Working Mechanism of Ball Screws:

1. Rotational Input: The process begins with the application of rotational input to the screw shaft. This rotational force causes the screw shaft to turn, and the helical groove guides the ball bearings along its path.

2. Circulating Ball Bearings: As the screw shaft rotates, the ball bearings circulate within the helical groove. This circulating motion minimizes friction and distributes the load evenly along the length of the screw.

3. Linear Motion Output: The movement of the ball bearings within the ball nut translates the rotational motion of the screw shaft into linear motion. This linear motion is harnessed for various applications, providing precise and controlled movement.

Advantages of Ball Screw Mechanism:

1. Efficiency: The rolling motion of ball bearings significantly reduces friction, leading to higher mechanical efficiency. This efficiency not only enhances performance but also contributes to energy savings.

2. Precision and Repeatability: Ball screws are renowned for their ability to provide precise and repeatable linear motion. This characteristic is crucial in applications where accuracy is paramount, such as in manufacturing and robotics.

3. Backlash Reduction: The design of ball screws minimizes backlash, ensuring that there is minimal clearance between the screw and nut. This reduction in backlash contributes to improved positioning accuracy.

Applications of Ball Screws:

Ball screws find widespread use in industries requiring precise linear motion, including:

CNC Machinery

Robotics

Aerospace Applications

Medical Devices

Semiconductor Manufacturing

In summary, the operation of ball screws is a testament to the ingenuity of mechanical engineering. By harnessing the principles of circulating ball bearings and helical grooves, these devices offer unparalleled efficiency and precision in converting rotational motion into controlled linear movement. A fundamental understanding of how ball screws work is essential for engineers and designers seeking optimal solutions for their mechanical systems.