What is a Belt-Driven Linear Actuator?

A belt-driven linear actuator is a type of mechanical system that converts rotational motion into linear movement using a belt and pulley mechanism. This system is commonly used in industrial automation, robotics, and material handling applications where high-speed and long-stroke movement is required. Unlike ball screw actuators, which rely on a threaded screw mechanism, belt-driven actuators offer a cost-effective and efficient solution for applications needing rapid and smooth linear motion.

Why Use Belt-Driven Linear Actuators?

Belt-driven linear actuators provide high-speed operation, long travel lengths, and low maintenance requirements, making them ideal for automation applications that require rapid movement and smooth operation. They are lightweight, energy-efficient, and capable of handling high acceleration and deceleration rates while maintaining precision and reliability.

What is a Belt-Driven Linear Actuator Used For?

Belt-driven linear actuators are widely used in various industries, including packaging, automotive, and electronics manufacturing. They are commonly integrated into conveyor systems, pick-and-place machinery, and positioning applications where fast and continuous motion is required. Due to their long travel capabilities and high-speed performance, they are also used in CNC machining, printing, and semiconductor processing equipment.

Browse our Belt-driven Linear Actuators

To explore further, let’s compare belt-driven actuators with ball screw actuators and examine why LIMON’s belt-driven actuators stand out.

Which Is Better: Belt-Driven or Ball Screw Actuators?

The choice between belt-driven and ball screw actuators depends on the specific requirements of the application.

Belt-driven linear actuators excel in high-speed and long-travel applications, as they offer smooth and rapid motion with minimal noise. They are also more cost-effective and require less maintenance compared to ball screw actuators.

On the other hand, ball screw actuators provide higher precision and load-carrying capabilities, making them suitable for applications requiring high accuracy and force transmission. While they offer better positioning control, they are typically more expensive and have limitations in terms of travel length and speed.

For applications that prioritize speed, efficiency, and lower operational costs, belt-driven linear actuators are the preferred choice. However, for precision-oriented applications that demand minimal backlash and high rigidity, ball screw actuators may be the better option.

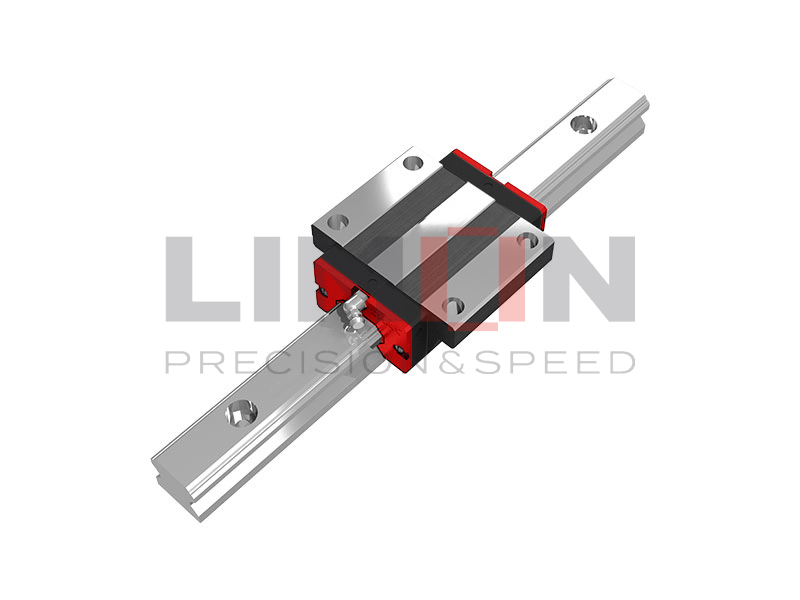

Why LIMON Belt-Driven Linear Actuators?

LIMON’s belt-driven linear actuators are designed with industry-leading quality and performance in mind. With advanced manufacturing processes and rigorous quality control, LIMON provides actuators that offer:

- High-Speed Performance:Capable of achieving rapid acceleration and deceleration with minimal noise.

- Long Travel Lengths:Suitable for extended linear motion applications without compromising efficiency, we used to offer 12 meters solution to LIMON partner.

- Robust and Durable Design:Engineered for industrial applications, ensuring longevity and reliability.

- Customizable Solutions:LIMON offers tailored actuator designs to meet specific application requirements, gantry system is available.

- Energy Efficiency:Reduced power consumption compared to traditional linear motion systems.

By choosing LIMON’s belt-driven linear actuators, industries can achieve optimal performance in automation and motion control applications.

Conclusion

Belt-driven linear actuators are ideal for high-speed and long-travel applications, providing efficiency, reliability, and cost-effectiveness in industrial automation.