Ignoring assembly requirements for ball screws can lead to misalignment, early wear, and costly failures. Understanding proper assembly ensures reliable performance and longer system life.

Ball screw assembly capabilities define the procedures, mounting requirements, and design considerations needed for durability and efficiency. Proper practices improve accuracy, minimize wear, and extend service life in demanding applications.

Let’s now explore the details of ball screw assembly and how to achieve optimal performance.

Selection Procedures

Selecting the right ball screw assembly begins with understanding the application’s load, speed, and accuracy requirements. Engineers need to evaluate several parameters, such as screw diameter, lead, stroke length, and preload type. Each choice affects performance, efficiency, and lifespan. For example, a higher lead offers faster linear travel but requires more torque, while smaller leads deliver better positional accuracy but slower speeds.

Another critical selection factor is environmental condition. Ball screws exposed to dust, moisture, or extreme temperatures require additional protective features such as seals, wipers, or specialized lubricants. Similarly, vertical applications need to consider back-driving forces, which may necessitate the use of a brake or self-locking nut.

Precision grades also guide selection. High-precision ground ball screws are common in CNC machines and semiconductor equipment, while rolled ball screws are sufficient for less demanding automation tasks. Matching the screw’s accuracy grade with the application prevents unnecessary costs and ensures efficiency. Proper selection lays the foundation for effective assembly and long-term reliability.

Mounting Requirements

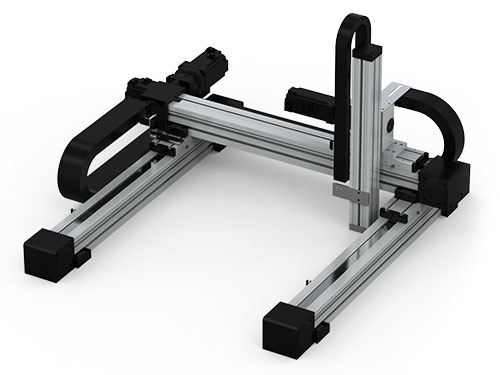

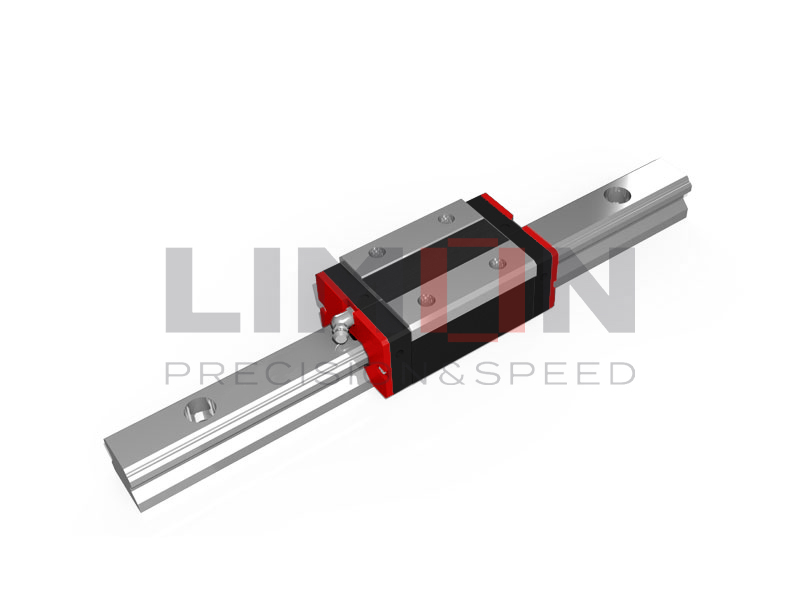

Mounting is one of the most crucial stages in a ball screw assembly. Even the best-designed ball screw will fail prematurely if incorrectly mounted. The mounting process involves aligning the screw shaft with the nut housing, securing support bearings, and ensuring proper preload without introducing stress.

End supports play a vital role in stability. Depending on the design, ball screws can be mounted with fixed–floating, fixed–supported, or double-fixed configurations. A fixed–floating setup allows for thermal expansion and is common in medium-load applications, while double-fixed setups are ideal for high-precision systems where rigidity is essential.

Tolerances in mounting surfaces must also be carefully observed. Any angular or parallel misalignment creates uneven loading, leading to localized stress, excessive heat, and rapid wear. To avoid this, surfaces should be machined to precise flatness, and bearing housings must be concentric. Proper tightening torque for bolts is equally important to prevent distortion of the support units. Mounting, when done correctly, guarantees smoother operation and minimizes vibration.

Design Considerations

Designing with ball screws requires balancing efficiency, accuracy, and durability. One of the most important considerations is load distribution. Engineers must calculate both static and dynamic load ratings to ensure the assembly can withstand forces throughout its operating life. Selecting a screw with insufficient capacity leads to premature fatigue and failure.

Lubrication is another critical design factor. Since ball screws operate with rolling contact, they demand a consistent lubricant supply to reduce friction and wear. Designers must include provisions for grease ports or centralized oiling systems. In high-speed applications, advanced lubrication systems with circulation or cooling functions may be required.

Thermal expansion is often overlooked but significantly impacts accuracy. Long ball screws expand when heated, potentially causing misalignment or jamming. To mitigate this, engineers can use floating supports, thermal compensation methods, or choose materials with lower thermal expansion coefficients.

Noise and vibration control also matter. Selecting appropriate preload methods, such as double-nut preload or offset preload, enhances stiffness and minimizes backlash. These considerations ensure that the ball screw assembly performs optimally under real-world conditions.

Comparative Table of Ball Screw Assembly Considerations

| Aspect | Key Factors | Common Issues if Ignored | Recommended Practices |

|---|---|---|---|

| Selection | Load, speed, accuracy, environment, screw grade | Premature wear, inefficiency, high cost | Match application with correct grade and lead; consider environment |

| Mounting | Alignment, end support type, preload, torque | Misalignment, vibration, heat, early failure | Use precise tolerances, correct support configuration, proper torque |

| Design Considerations | Load distribution, lubrication, thermal expansion, preload | Fatigue, lubrication failure, jamming, backlash | Calculate ratings, provide lubrication, compensate expansion, minimize noise |

Conclusion

Ball screw assembly requires proper selection, precise mounting, and thoughtful design. Mastering these ensures durability, accuracy, and long-lasting performance.For further questions please contact [email protected]

_1.jpg)