What is a Ball Chain Type Linear Guide?

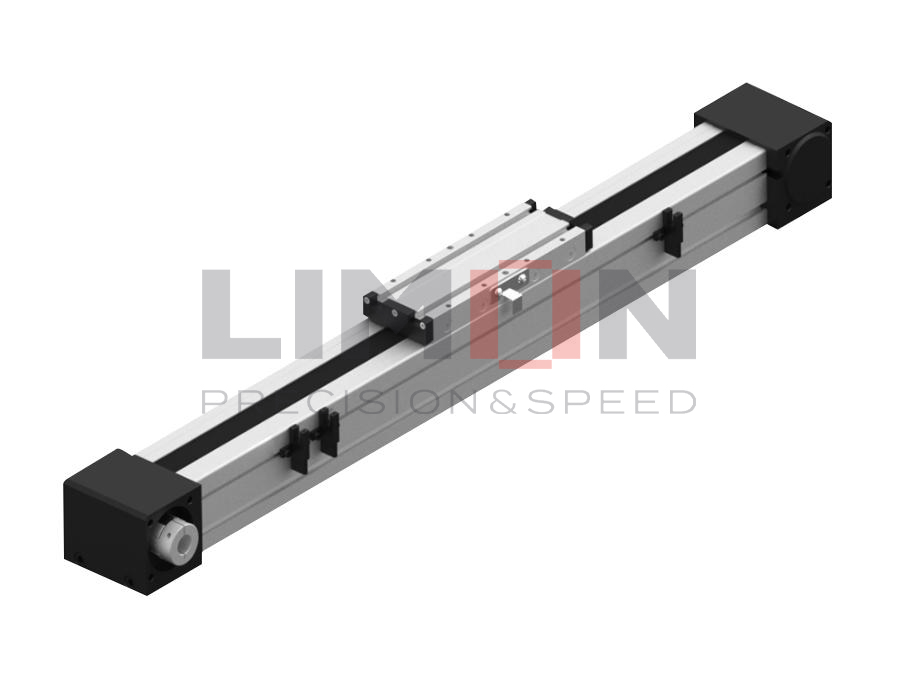

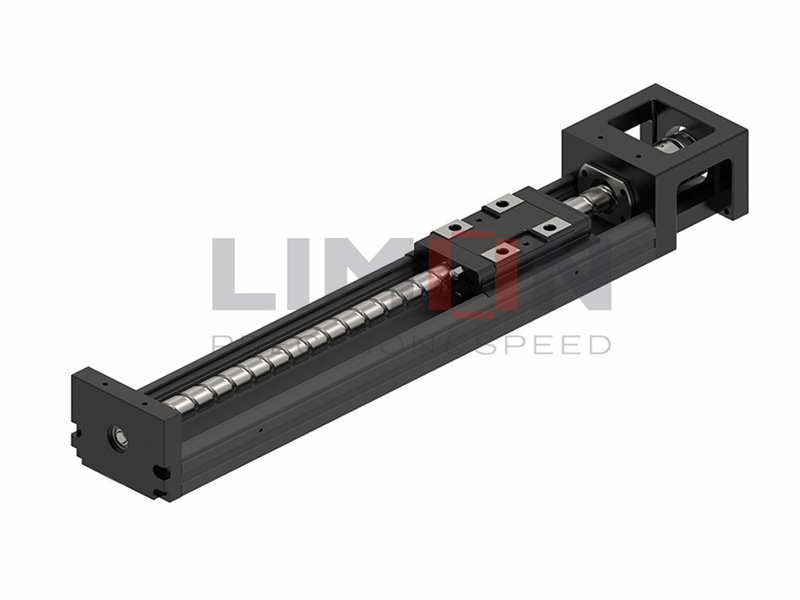

A ball chain type linear guide is a precision motion component designed to enable smooth, stable, and high-speed linear movement in industrial applications. It features a patented ball chain mechanism that ensures consistent contact between the carriage and rail, minimizing friction and enhancing load distribution. Unlike traditional linear guides, this design incorporates a self-aligning capability, which adapts to minor misalignments during installation or operation, making it ideal for high-accuracy automation systems. Its compact structure and optimized four-directional load capacity allow it to withstand heavy forces while maintaining rigidity—critical for applications like CNC machinery, robotics, and semiconductor manufacturing.

Why Use Ball Chain Type Linear Guide?

Ball chain type linear guides excel in high-speed, high-precision automation industries. Their unique ball chain design reduces noise, ensures smooth motion, and offers superior lubrication efficiency. With self-alignment capabilities and flexible installation options (top/bottom mounting), they outperform conventional guides in demanding environments.

Which Is Better: Regular Type or Ball Chain Type?

Continue reading to uncover why LIMON’s innovation redefines linear motion.

Why LIMON Ball Chain Type Linear Guide?

- How Does the Patented Ball Chain Design Enhance Performance?

LIMON’s ball chain mechanism links individual recirculating balls into a continuous chain, eliminating uneven load distribution common in standard designs. This configuration reduces vibration and noise by up to 30%, crucial for noise-sensitive environments like medical equipment. The chain’s synchronized movement also minimizes heat generation, extending service life in high-speed applications such as packaging machinery.

- What Makes Installation Flexibility a Game-Changer?

LIMON guides support both top- and bottom-side carriage mounting, accommodating space-constrained setups without compromising rigidity. For instance, in robotic arms with limited vertical clearance, bottom mounting simplifies integration. This adaptability reduces design overhaul costs and accelerates deployment in modular automation systems.

- How Does Structural Optimization Improve Rigidity?

By extending carriage length while maintaining compact dimensions, LIMON enhances rigidity without increasing height. This is vital for CNC machines where cutting forces demand anti-deflection properties. The extended contact area distributes loads evenly, sustaining accuracy even under prolonged stress.

- Why Is Lubrication Efficiency Critical for Longevity?

The ball chain’s closed-loop design retains lubricant more effectively than open-track systems, reducing maintenance frequency. In dusty environments like woodworking plants, this feature prevents particulate ingress, ensuring consistent motion and lowering downtime.

- How Does LIMON Cater to Diverse Automation Industry Needs?

From semiconductor lithography (requiring micron-level precision) to automotive assembly lines (demanding high load capacity), LIMON’s guides adapt seamlessly. Their compatibility with modular linear motion products allows manufacturers to standardize components across machinery, streamlining supply chains.

- What Cost Advantages Do LIMON Guides Offer?

Despite advanced features, LIMON maintains cost efficiency through standardized dimensions. Users avoid custom tooling expenses, while the extended lifespan and reduced maintenance lower total ownership costs by ~20% over conventional models.

Conclusion

LIMON’s ball chain linear guides redefine precision, durability, and adaptability—essential for tomorrow’s automation challenges. Explore how this innovation elevates your motion systems.