Unexpected bearing failures disrupt operations, delay production, and lead to costly repairs. Without proper maintenance, even high-quality linear bearings degrade prematurely. Implementing these 5 essential tips ensures uptime and reliability.

Regular linear bearing maintenance prevents failures, extends lifespan, and ensures precision in motion systems. By following best practices like routine inspection, training, and proper installation, downtime can be minimized.

Maintenance is not just a checklist—it’s a strategy. Let’s explore how you can act before breakdowns happen.

Implement A Strict & Regular Linear Bearing Maintenance Schedule

A proactive maintenance schedule is the first line of defense against unexpected bearing failures. Linear bearings are precision components that rely on a clean, lubricated surface to function efficiently. Without a structured plan, wear and contamination quickly set in.

Establish daily, weekly, and monthly inspection protocols. Daily checks might include visual inspection for debris or signs of overheating. Weekly tasks could involve re-lubrication or cleaning of guide rails. Monthly reviews may cover measuring clearances or vibration patterns that indicate internal damage.

Use a checklist system to ensure no step is skipped. Maintenance software can help automate reminders and documentation. Keep a logbook for every linear bearing system to track wear patterns and predict replacement intervals.

Failing to implement a maintenance schedule often leads to unnoticed deterioration, which accelerates wear, decreases machine accuracy, and ultimately causes complete system shutdown.

Preventive Maintenance Of Your Linear Bearings

Preventive maintenance goes beyond reactive repair—it’s about anticipating issues before they occur. This approach reduces unexpected downtime and preserves the lifespan of your linear bearing system.

Start by selecting the correct lubricant based on the manufacturer’s specifications and environmental factors (temperature, dust, humidity). Consistently apply it at recommended intervals, and consider using automatic lubricators for hard-to-reach components.

Inspect linear bearings for signs of wear, including unusual noise, increased friction, or vibration. Clean the shaft or rail thoroughly before each lubrication to avoid grinding particles into the raceways.

Preventive measures also include replacing worn seals, checking alignment, and ensuring that preload settings have not changed. These tasks maintain smooth motion and reduce internal stress on the bearing structure.

By treating linear bearing systems as critical components requiring active management, you build a culture of reliability throughout your operation.

Training Your Operators To Identify Early Causes Of Linear Bearing Failure

Even the best maintenance protocols can fail if your operators don’t recognize early warning signs. A well-trained team becomes your first alert system for potential linear bearing issues.

Train personnel to listen for abnormal noises like grinding or squealing, which often indicate lubrication failure or misalignment. Teach them to observe motion inconsistencies or increased resistance when moving along the axis.

Provide visual charts or samples of bearing wear for reference. Include education on how operating conditions like excessive loads, uneven forces, or environmental contaminants can contribute to premature failure.

Establish a reporting process so observations are logged and investigated promptly. Simple operator checklists at the beginning and end of shifts can lead to early detection and quick fixes, avoiding major repairs.

With training, operators become not just users—but active participants in bearing preservation.

Conduct Regular Linear Bearing Inspections

Inspections are essential for catching mechanical problems before they develop into performance-critical failures. These assessments should be scheduled regularly and follow a structured methodology.

Begin with visual inspection: look for rust, grease leakage, debris accumulation, or surface wear. Follow this with manual inspection, checking smoothness of travel and any unusual vibration or noise. Use feeler gauges or dial indicators to measure clearance or misalignment.

Pay attention to the guide rails and shafts, as they often suffer from the same wear and contamination issues as the bearing itself. Clean them with lint-free cloths and appropriate solvents.

Some modern linear bearing systems come with condition monitoring sensors, which track temperature, vibration, or travel speed. These provide data-driven insights and alert operators before performance drops.

Ultimately, a well-documented inspection routine helps anticipate when replacement is needed and prevents total system breakdowns.

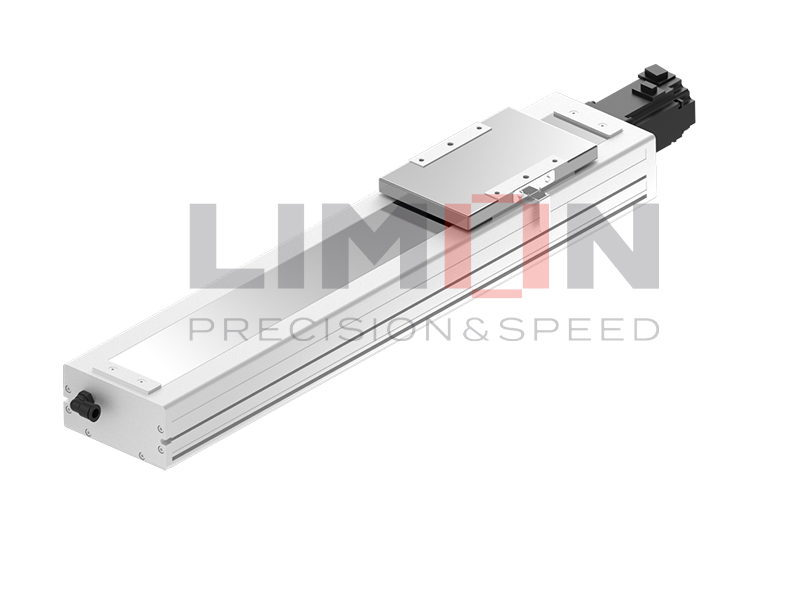

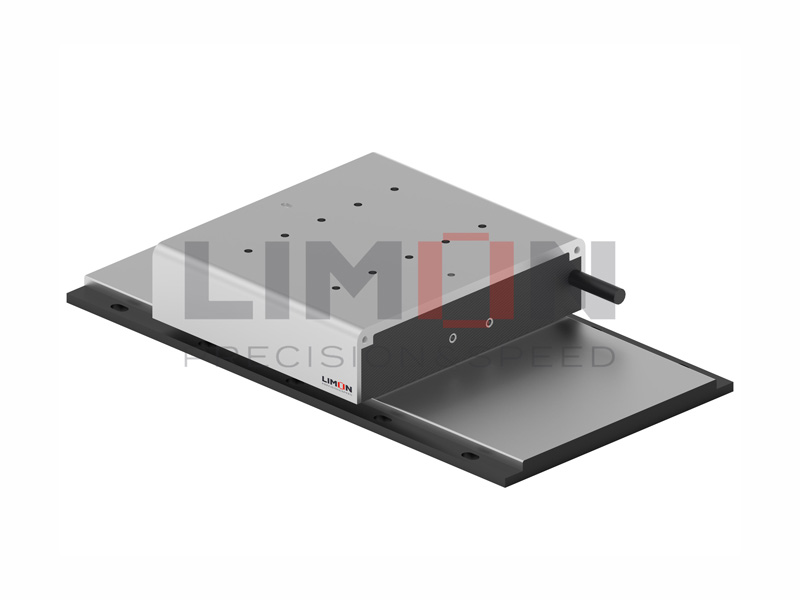

Proper Installation Of Your Linear Bearings

Correct installation is a foundational step in ensuring the longevity of your linear bearings. Misalignment, incorrect preload, or contamination during assembly can drastically shorten bearing life—even before the system goes operational.

Begin by thoroughly cleaning the mounting surfaces to remove any dust, debris, or machining residues. All surfaces must be flat and properly aligned to prevent unwanted stress during motion. Use torque wrenches to tighten fasteners according to specifications—over-tightening or under-tightening can create uneven loading.

When handling linear bearings, avoid touching raceways with bare hands to prevent corrosion from skin oils. Use clean gloves and handle components with care.

Check shaft or rail parallelism using precision measuring instruments. If the system includes two or more linear guides, misalignment between them can cause binding or stress concentration.

Document every installation step and verify results using alignment tools or calibration lasers. A precise installation ensures consistent load distribution, smooth motion, and maximum bearing lifespan.

Conclusion

Proper care and discipline in linear bearing maintenance prevent downtime and preserve productivity.For further questions please contact [email protected]