What is linear rails and how linear rail dimension selection?

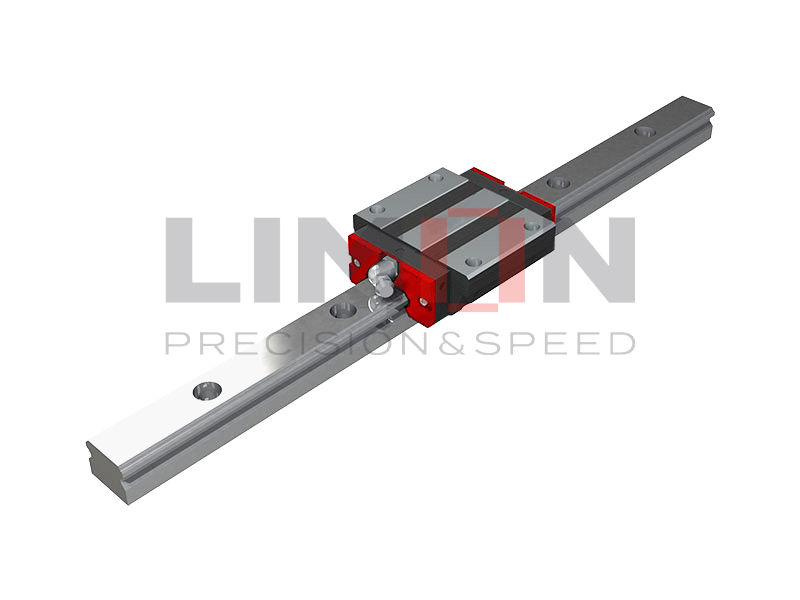

Linear rails are a block and rail system that helps support the motion of an application.There are two parts to the Linear rail System: the Linear Block and the Linear Rail. The linear block moves along the linear rail along the plane the rail is positioned for. The block moves forward and backward along the straight linear rail. Linear blocks connect to the moving components by mounting to the block to support the motion for the specified component. The motion is created along the rail through recirculating ball bearings within the block that is contacted on the rail.

How about the linear rails application?

Linear rails are used in a wide range of industrial and manufacturing applications. You will commonly see linear guides of all sizes and styles used in CNC machines and 3D printers, including in smaller home printers and larger industrial printers. In these applications, linear slides are often used to position a tool or base plate inside of the machine. While actuating is done by another component, the linear guide carries the weight of the tool or base plate and protects the actuating component from improper loading. Linear rails are also used in robotic applications and designs like with the Gantry (also called Cartesian) robots and with overhead transport systems. There are tons of applications where linear guides are used to support heavy loads and ensure smooth linear motion.

LIMON linear rail have several size from 15~65 to meet different applications.

How about linear rail dimension selection?

When choosing linear rail dimension, firstly, determine the width of the rail, that is the width of the slide rail.Rail width is one of the important key factors to determine the load size.

- Check how about the length of linear rails.

The end user should pay attention on the linear rail dimension selection.

Total length = effective stroke + spacing of block (more than 2 blocks) + length of block × number of block+ safe stroke of both ends.If a protective cover is added, increase the compression length of the protective cover at both ends.It should be noted that before asking the brand of the whole length of the guide rail, more than this length needs docking.

- The spacing of mounting holes on the linear guide is fixed.

The end users should pay attention on location when determining track length.If they don’t tell the supplier the size of the end they need.In general, the arriving state is 10 mounting holes.The distance between the two ends of the guide rail and the center of the respective mounting hole is 30.30, but it may be of other sizes.Each brand has slightly different shipping specifications for end sizes, with most brands having equal ends by default.

- Confirmed the type and quantity of block.

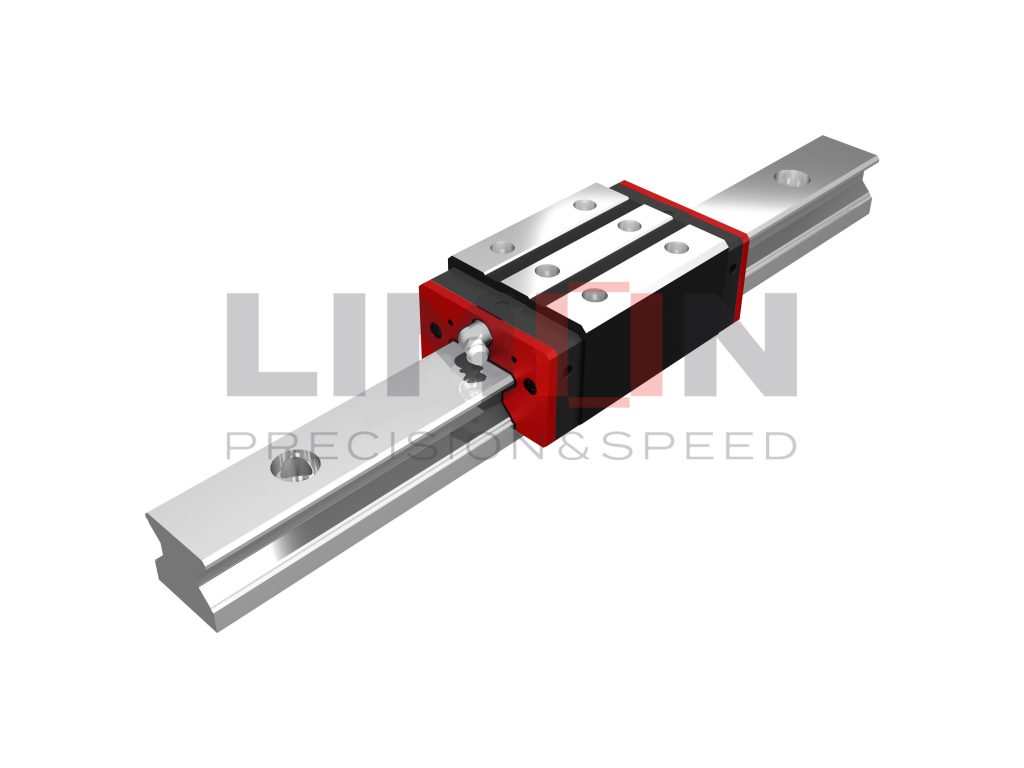

There are two kinds of block commonly used in linear guide, namely flange type and square.The former is lower but wider.The mounting hole is threaded through the threaded hole, which is higher and narrower.The mounting holes are threaded blind.Both are available in short and standard and extended forms.The main difference lies in the length of the slider body;Of course, the spacing between mounting holes may vary.

Above is the introduce of linear rail dimension selection.

_1.jpg)