In the world of precision motion control, selecting the right motor hinges on understanding the control method behind it. Let’s compare the LIMON stepper motor and the servo motor in terms of control strategies and operating principles.

What’s the Main Difference in Control Method?

LIMON Stepper Motor – Open-Loop Control

-

Operates via open-loop control — no feedback mechanism.

-

Receives electrical pulses, and for each pulse, it moves a fixed step (angular increment).

-

Ideal for applications requiring repeatable, low-speed motion without real-time adjustment.

-

Cost-effective, simple setup, but limited in handling dynamic loads or high-speed variations.

Servo Motor – Closed-Loop Control

-

Uses a closed-loop system with feedback from an encoder or resolver.

-

Continuously adjusts position, speed, and torque in real-time.

-

Delivers superior accuracy and load adaptability.

-

Common in high-performance systems such as robotics, CNCs, and automation lines.

The Principle of the LIMON Stepper Motor

Based on Electromagnetic Induction and Stepwise Motion

The LIMON stepper motor converts electrical pulses into discrete mechanical steps, making it ideal for applications that require accurate positioning without complex feedback systems.

Basic Construction of a LIMON Stepper Motor

Stator

-

The stationary component with multiple electromagnetic coils arranged in phases.

-

These coils are energized in a sequence to generate a rotating magnetic field.

Rotor

-

The moving part of the motor, made of permanent magnets or a toothed soft iron core.

-

It aligns with the stator’s magnetic field to produce precise step-by-step rotation.

How It Works:

-

Pulses are sent to the stator windings in a specific phase sequence.

-

The rotor aligns with the resulting magnetic field.

-

Each pulse results in a fixed angular displacement—a “step.”

Conclusion: Why Choose a LIMON Stepper Motor?

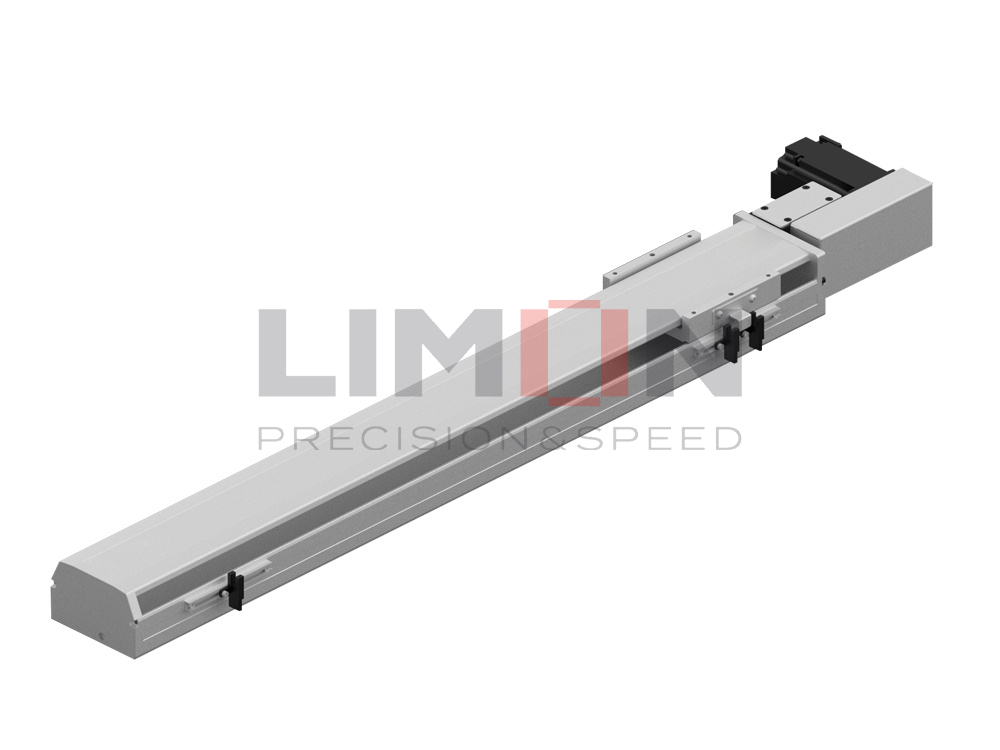

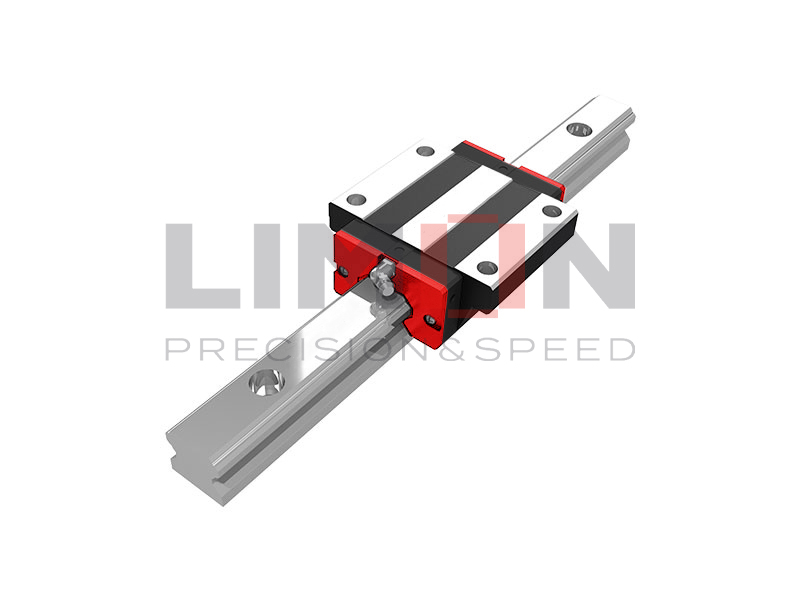

If your application demands cost-effective, open-loop precision motion without the complexity of feedback systems, the LIMON stepper motor is a smart choice. While it lacks real-time adaptability like a servo motor, it shines in low-speed, high-repeatability tasks such as 3D printers, pick-and-place machines, and linear stages.