Precision motion systems often suffer from high friction, backlash, and wear—leading to reduced accuracy, frequent downtime, and costly replacements. Ball screws can solve these issues and enhance performance.

Ball screws deliver high-efficiency, low-backlash linear motion with excellent load capacity, but they require careful maintenance and alignment to maximize their benefits.

Continue reading to weigh the advantages and disadvantages of ball screw systems.

Ball Screws Vs Lead Screws: What’s The Difference?

Ball screws and lead screws both transform rotary to linear motion, but they function differently.

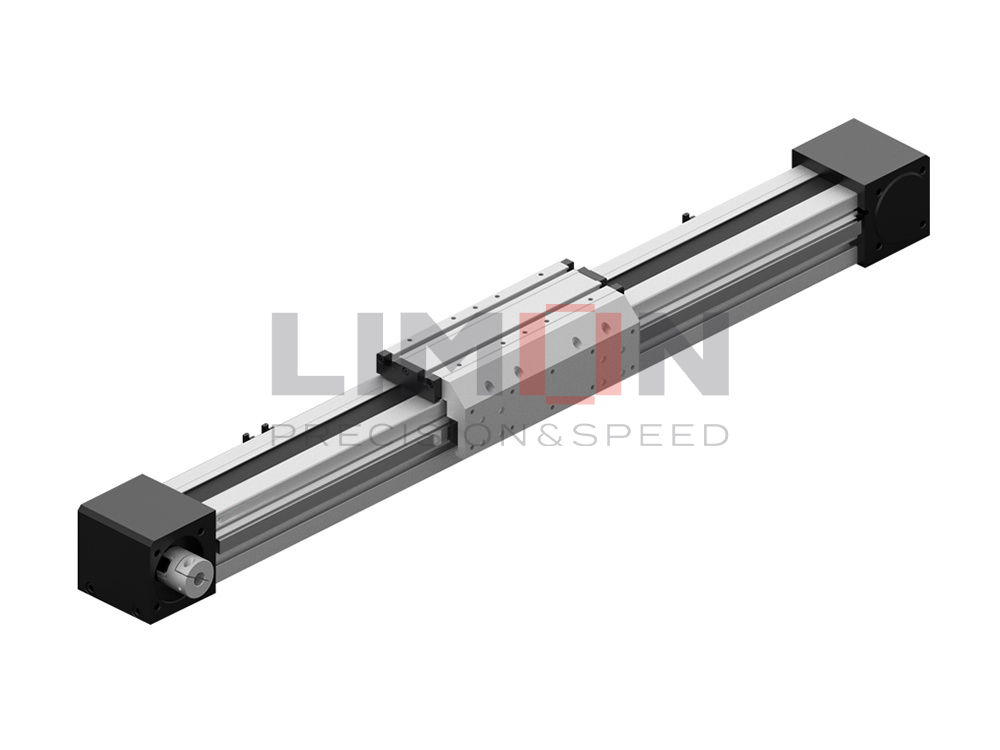

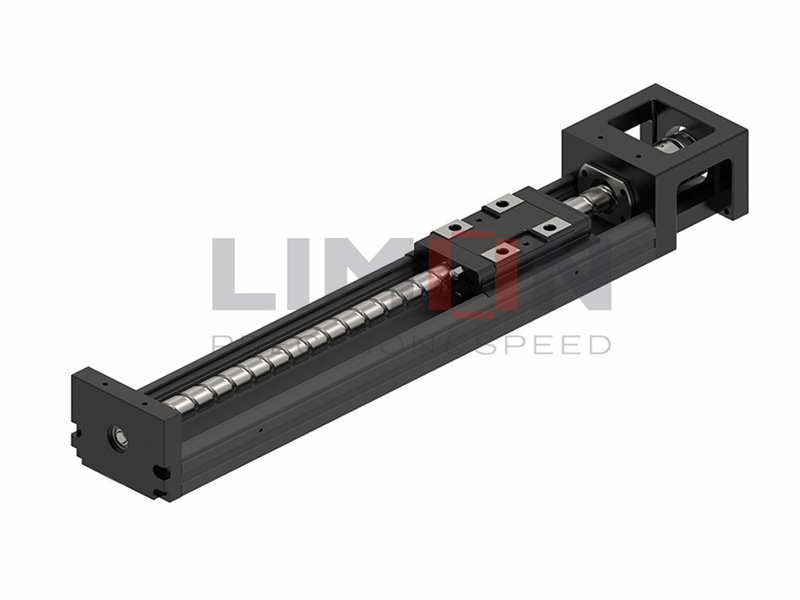

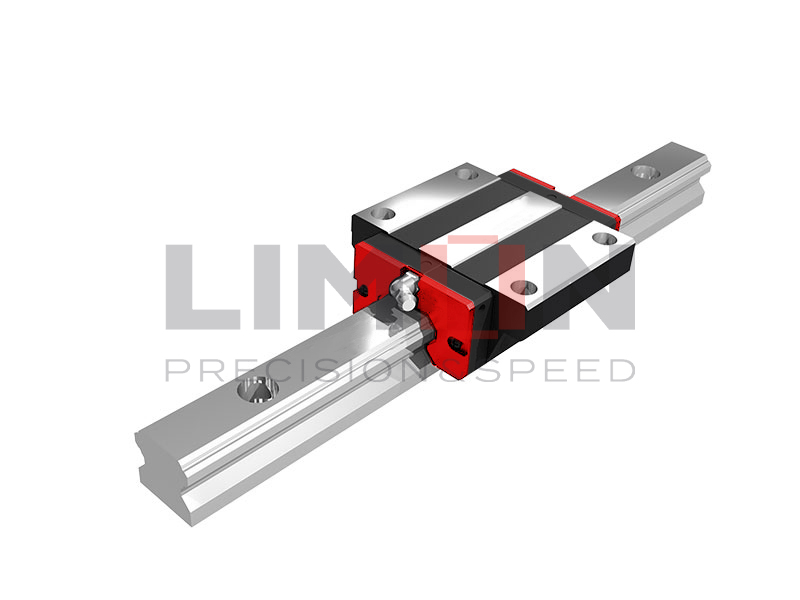

Ball Screw: Incorporates recirculating steel balls between the screw and nut, creating rolling contact. This design offers high efficiency (90–98%), low friction, high repeatability, and low backlash—ideal for high-speed, high-precision systems.

Lead Screw: Uses sliding contact between the nut and screw threads, resulting in lower efficiency (30–50%), higher friction, and inherent self-locking—advantageous in vertical loads but limited in speed and lifespan.

Ball screws outperform in accuracy, speed, and energy efficiency but without self-locking ability—lead screws excel when simplicity and downtime are acceptable. Proper system analysis helps determine which is best for your application.

Advantages Of Ball Screws

High Mechanical Efficiency

Rolling bearings reduce friction significantly, allowing high-speed motion while minimizing heat buildup and energy losses.High-Precision and Low Backlash

Preloaded nuts enable tight control, micrometer-level positioning, and consistent repeatability.Excellent Load Capacity

They support heavy axial and dynamic loads accurately over long travels without loss of stiffness.High Speed Capabilities

With low wear and precise machining, ball screws can sustain speeds exceeding 5,000 RPM on modern machines.Longevity and Predictability

Hardened components and standardized ratings allow engineers to predict life expectancy based on loads and lubrication schedules.Energy Efficiency

Less force is required to maintain desired motion, reducing motor size and power consumption.Integration with Feedback Systems

Their low backlash makes precise servo and encoder feedback loops more effective.

Disadvantages Of Ball Screws

High Initial Cost

Precision manufacturing, bearing-grade steel, and preloaded nuts contribute to significantly higher prices than lead screws.Lack Of Self-Locking

They back-drive under load; external brakes or holding mechanisms are necessary for vertical or static-load applications.Sensitivity To Contamination

Contaminants like dust or chips can enter the nut and damage recirculating elements, necessitating effective sealing.Maintenance Requirements

Require regular lubrication, seal inspection, and alignment checks to preserve performance and prevent premature wear.Alignment Precision Needed

Misalignment can cause uneven loading, noise, vibration, and reduced life—machined rails and precision assembly are essential.Complexity Of Installation

Preload selection, nut mounting, shaft support design, and coupling choices add design and installation complexity.

Summary

Ball screws offer unmatched precision, high efficiency, and load capacity, but they demand careful maintenance, alignment, and cost investment—ideal when accuracy outweighs complexity.For further questions please contact [email protected]