High-friction, imprecise transmission systems can ruin high-performance machinery. Left unchecked, this leads to inefficiency, wear, and costly downtime. The solution? Choose the right ball screw design for your needs.

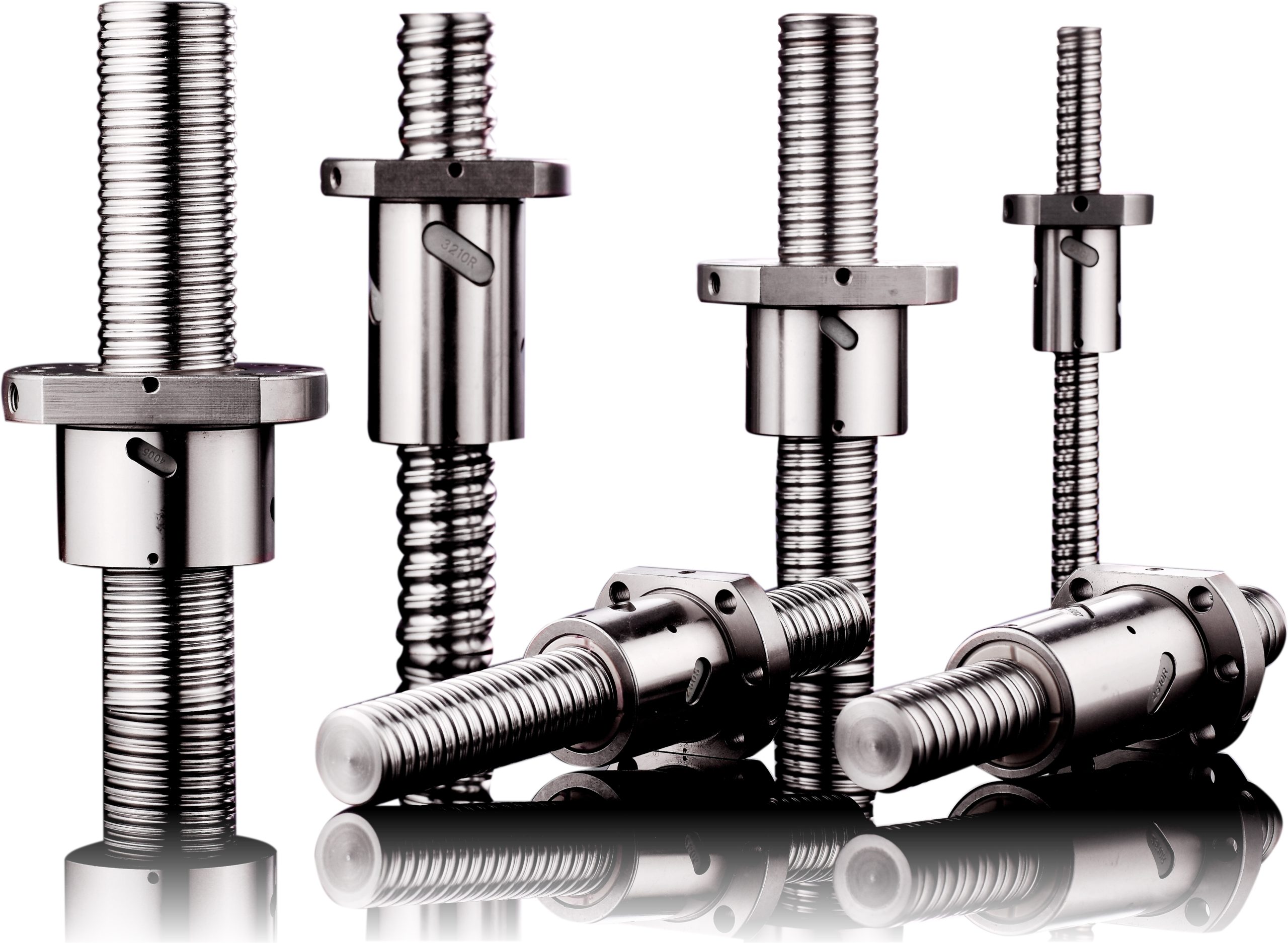

Ball screws come in various specialized types—each offering unique features like high speed, silent operation, or self-lubrication—to meet specific demands in industrial automation and precision control.

Explore each type in depth and discover which ball screw configuration fits your system best.

Heavy-Duty Ball Screw

Heavy-duty ball screws are designed for high-load industrial applications, offering enhanced strength, durability, and efficiency. They are typically made with larger diameters and reinforced materials, allowing them to withstand substantial axial loads without deformation or loss of precision.

These ball screws are commonly used in injection molding machines, pressing equipment, and heavy-duty CNC machinery, where repeated high-force motion is required. Their preload capacity ensures minimal backlash, and the thick-walled nut designs provide excellent rigidity. Some models incorporate double nuts or oversized balls to increase load capacity and reduce deflection.

Thanks to robust construction and optimized ball circulation paths, heavy-duty ball screws also offer long service life and consistent performance even under extreme conditions. The trade-off, however, is slower rotational speed and greater inertia.

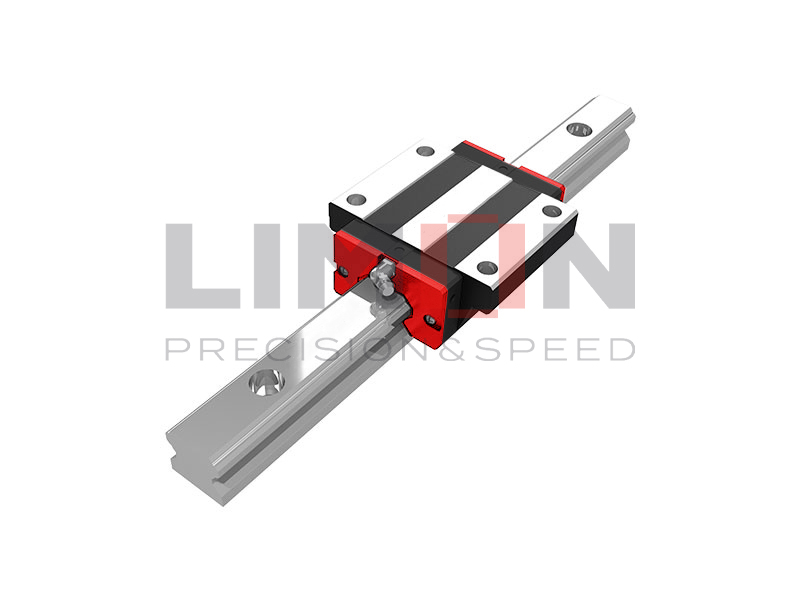

High-Speed Ball Screw

For applications where speed is critical, high-speed ball screws offer reduced friction and enhanced dynamic performance. These screws feature optimized ball return paths and are designed with smaller pitch angles to enable high rotational velocities with minimal vibration.

Common in semiconductor manufacturing, pick-and-place equipment, and high-speed CNC routers, these ball screws can operate at speeds exceeding 10,000 rpm while maintaining high precision. The use of low-friction seals and advanced lubrication systems ensures temperature stability and extended operating life.

Key engineering considerations for high-speed ball screws include critical speed, dN value (bearing diameter x speed), and vibration damping. Designs often include hollow shafts or balanced flanges to support better dynamic performance.

The Cooled Ball Screw

Cooled ball screws incorporate internal or external cooling channels that help regulate the temperature of the system during high-duty operations. Heat buildup in standard ball screws can lead to thermal expansion, affecting accuracy and causing premature wear.

Cooled ball screws solve this by circulating a coolant (typically oil or water-glycol mixture) either through the shaft bore or via external jackets surrounding the nut or screw shaft. This maintains dimensional stability, minimizes thermal drift, and ensures consistent performance during prolonged or high-load cycles.

Used extensively in injection molding, machine tools, and die-casting systems, cooled ball screws are ideal for environments where thermal management is essential. These systems often require specialized plumbing and additional maintenance but provide unmatched thermal stability.

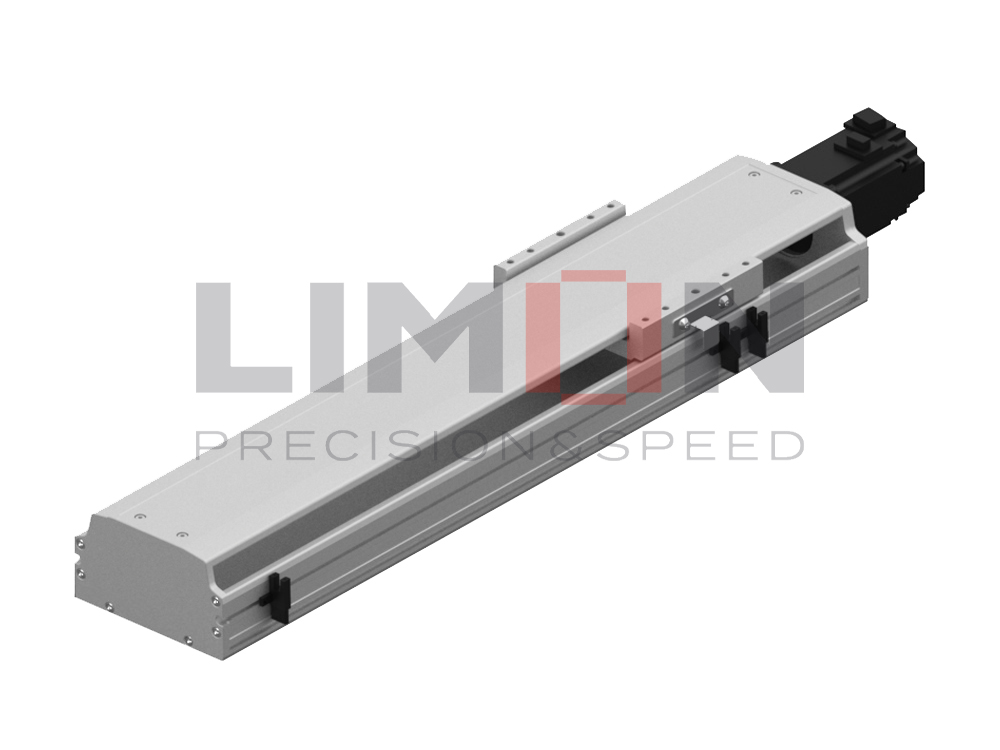

Nut-Rotating Ball Screw

In nut-rotating ball screw systems, the screw shaft remains stationary while the ball nut itself rotates. This configuration is particularly beneficial when space constraints exist, or when it’s advantageous to fix the screw and move only the load via the rotating nut.

These systems are common in robotics, medical devices, and automated optical machinery, where the reduced inertia and compact form factor improve performance. A rotating nut setup can also simplify linear module integration and enable direct-drive motor coupling.

Precision alignment and high-quality bearings are critical in these systems to maintain load symmetry and avoid radial imbalance. Nut-rotating ball screws also reduce the effects of shaft whipping at high speeds.

Self-Lubricating Ball Screw

Self-lubricating ball screws reduce maintenance by incorporating built-in lubrication elements. These typically include oil-impregnated felt liners, lubrication cartridges, or polymer reservoirs that automatically deliver lubricant to the ball screw contact areas.

Ideal for environments where manual lubrication is impractical—like in sealed machines or cleanrooms—these ball screws significantly extend maintenance intervals while maintaining optimal performance. The integrated lubrication system helps to reduce wear, eliminate dry starts, and prolong the overall lifespan of the assembly.

Applications include medical devices, semiconductor equipment, and food-grade machinery. Most self-lubricating ball screws are paired with seals or wipers to prevent contamination and retain lubrication over long cycles.

Silent Ball Screw

Silent ball screws are engineered to minimize noise and vibration during operation. They employ design improvements such as helical grooves, optimized ball circulation paths, and dampening inserts to reduce acoustic emissions.

These ball screws are ideal for applications where low noise is critical—such as in hospital equipment, office automation, or laboratory robotics. In many cases, noise levels can be reduced by up to 5–10 dB compared to standard ball screw systems.

They often come with a special polymer return circuit and low-friction coatings to reduce resonance. While silent ball screws may cost slightly more, they are essential in noise-sensitive environments and offer long-term user comfort and system reliability.

Summary

Choosing the right type of ball screw ensures optimal performance, whether it’s strength, speed, cooling, silence, or minimal maintenance you’re after.For further questions please contact [email protected]