Ball screws are indispensable in precision applications, from CNC systems to linear actuators. Understanding ball screws, particularly in comparison to lead screws, is vital for maintaining their performance and longevity. This guide offers an in-depth look at troubleshooting ball screws, highlighting their differences with lead screws, and emphasizing the importance of ball screw actuators in CNC applications.

Common Issues and Solutions

Noise and Vibration: Addressing Misalignment and Bearing Concerns

Unusual noise or vibration in ball screws often signals misalignment or issues with ball screw bearings. Proper realignment and careful inspection of these bearings are crucial for resolution.

Backlash and Accuracy Loss: Confronting Wear and Tear

Experiencing backlash or reduced accuracy in ball screws typically indicates wear in the ball screw nut or bearings. Ball screw repair, involving adjustment or replacement of these components, is necessary to restore precision.

Stiffness in Movement: The Importance of Lubrication and Cleanliness

Stiff movement in ball screws can result from inadequate lubrication or contamination. Regular cleaning and appropriate lubrication of both ball screws and the ball screw nut are essential

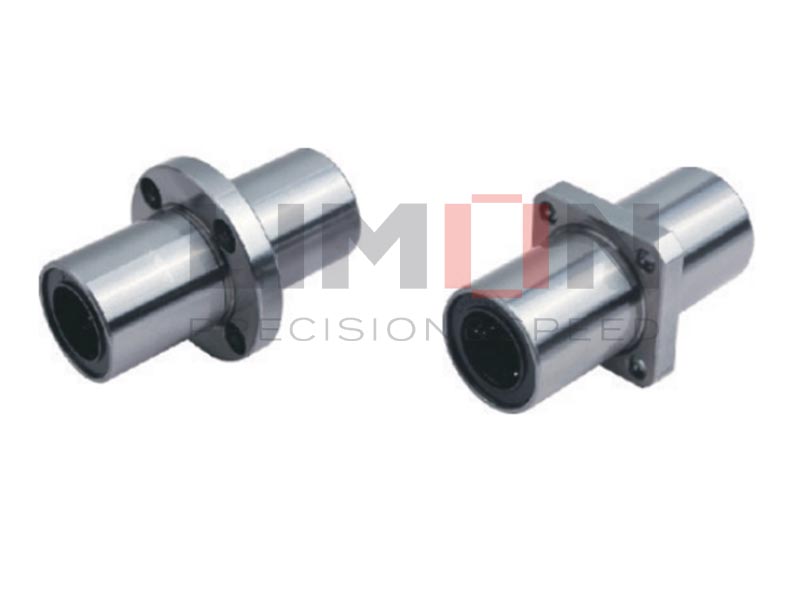

_1.jpg)

Ball Screws vs Lead Screws: Making the Right Choice

Discerning the differences between ball screws and lead screws is crucial for selecting the appropriate component for specific applications. Ball screws are preferred for high-precision and high-speed tasks, like in ball screw CNC machinery and ball screw linear actuators, owing to their superior efficiency and accuracy. Lead screws, however, are more suited for less demanding precision and speed requirements.

The Critical Role of Ball Screw Actuators

Ball screw actuators, especially those used in ball screw linear actuator setups, play a key role in precise motion control across various applications, including robotics and aerospace.

Preventive Measures

Implementing a preventive maintenance schedule, focusing on regular inspections, lubrication, and timely ball screw repair, can prevent many common issues. This approach not only prolongs the lifespan of ball screws but also ensures their reliability and efficiency, especially in demanding environments like ball screw CNC systems.

Ball screws, when contrasted with lead screws, offer unmatched precision and efficiency in demanding settings such as CNC machinery and linear actuators. Regular maintenance, understanding the nuances of ball screws versus lead screws, and the significance of ball screw actuators, bearings, and nuts are key to sustaining these high-performance components. Effective troubleshooting and diligent maintenance ensure that ball screws continue to function optimally, playing a crucial role in various industrial applications.