Want to know how does a Linear Actuator work?

So before we get to how does a linear actuator work, let’s start with what is the linear actuator? What is it made of and which industry is used for? After you understand how does a linear actuator work and the basics, it makes it easier for us to know what’s the point when choosing a linear actuator.

So what is a linear actuator?

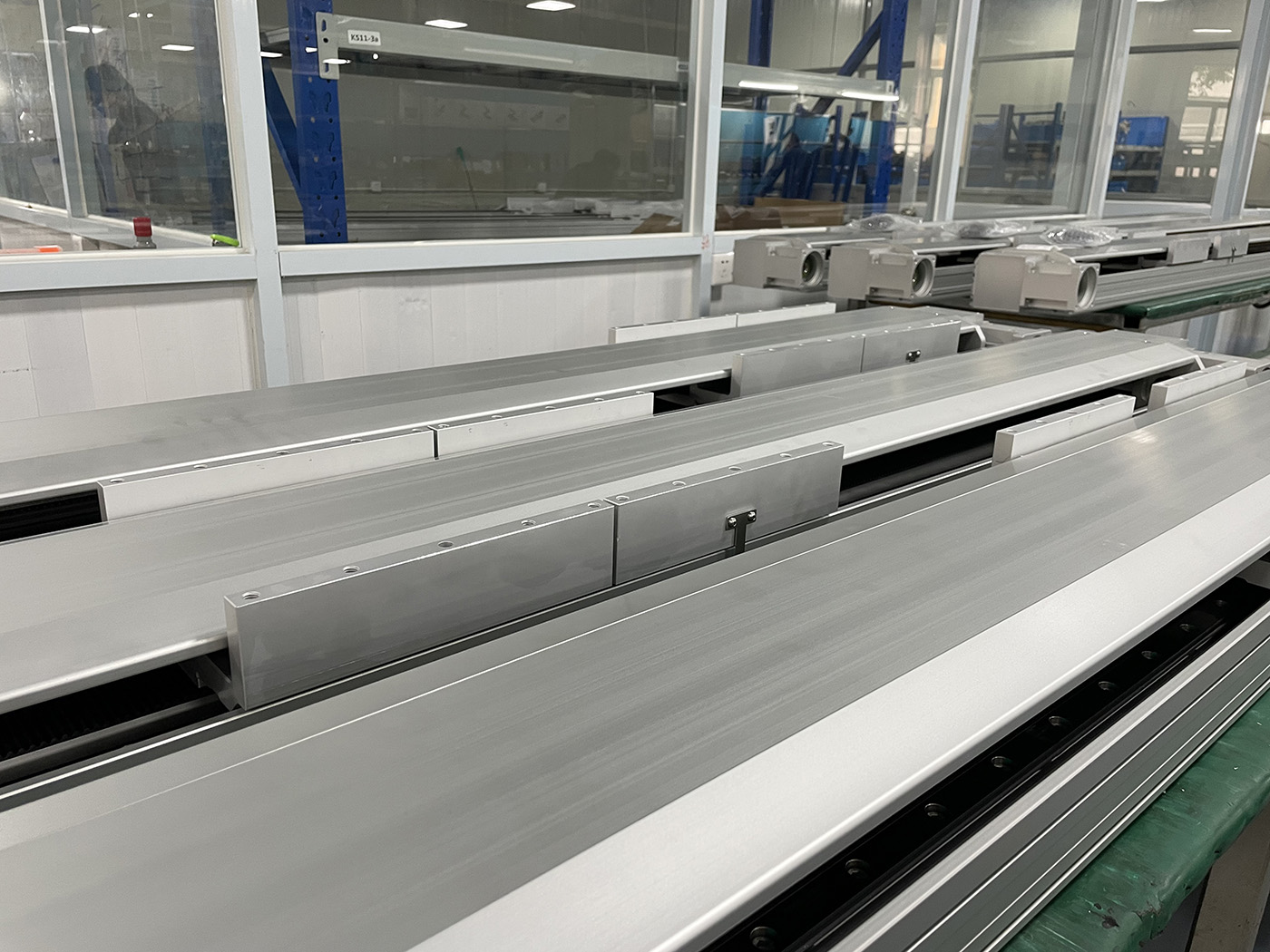

A linear actuator is a device that moves between two points in a linear motion, which is a set of equipment widely used in automation industry, like LED and semiconductor, even varied medical purposes, etc.

Linear actuator is a product composed of ball screw, linear guide, and timing belt. The Linear motion is created by using ball screw as they are more correctly called. The screw turns either clockwise or counter-clock-wise, and this causes the shaft, which is basically a nut on the screw to move up and down the screw as the screw turns. This is what convert rotary motion from the electric motor to linear motion.

Now lets get into how does a Linear Actuator work:

The name of linear actuator is also varied, including linear unit, electric cylinder, slide table and mechanical arm. Although the name is different, its working principle is the same.

It can be divided into belt driven and ball screw driven type, but the working principle of them are the same.Linear actuator is a modular product which integrates servo motor, screw and timing belt, which convert the servo motor rotation movement into linear motion, at the same time, convert the best advantage of servo motor: speed control precision, precise control of speed,revolution and torque into precise speed, position and thrust control of the actuator, and finally achieve high-precision linear motion, the working principle of belt and ball screw is described in detail below.

Working principle of Belt driven linear actuator:

Belt driven linear actuator is mainly composed of belt, linear guide, aluminum profile, coupling, motor, sensor and so on. The belt is mounted on the pulley block on either side of the linear actuator, and servo motor is mounted with the pulley block. When the input is in use, main carriage is driven by the belt. The belt linear actuator is usually designed specifically to control the tightness of the belt on one side, which facilitates the debugging of the equipment during production.The precision of the belt driven linear actuator depends on the belt quality and the combination of the assembly process. Control of power input can affect belt accuracy.

Working principle of Ball screw driven linear actuator:

It is mainly composed of ball screw, linear guide rail, aluminum profile, coupling, motor, sensor, etc. Ball screw is the ideal product for converting rotary motion into linear motion or linear motion into rotary motion. Ball screw is widely used in various industrial equipment and precision instruments because of its small friction resistance.

These are linear actuator operating principle, after you know how does a linear actuator work,you will according the application to choose the best match type.

For the linear actuator the most important thing is high precision.LIMON precision grasp is very high,We are not only can provide multi-axis combined project and also can offer customized service.This is why we get good reputation from the market.

_1.jpg)