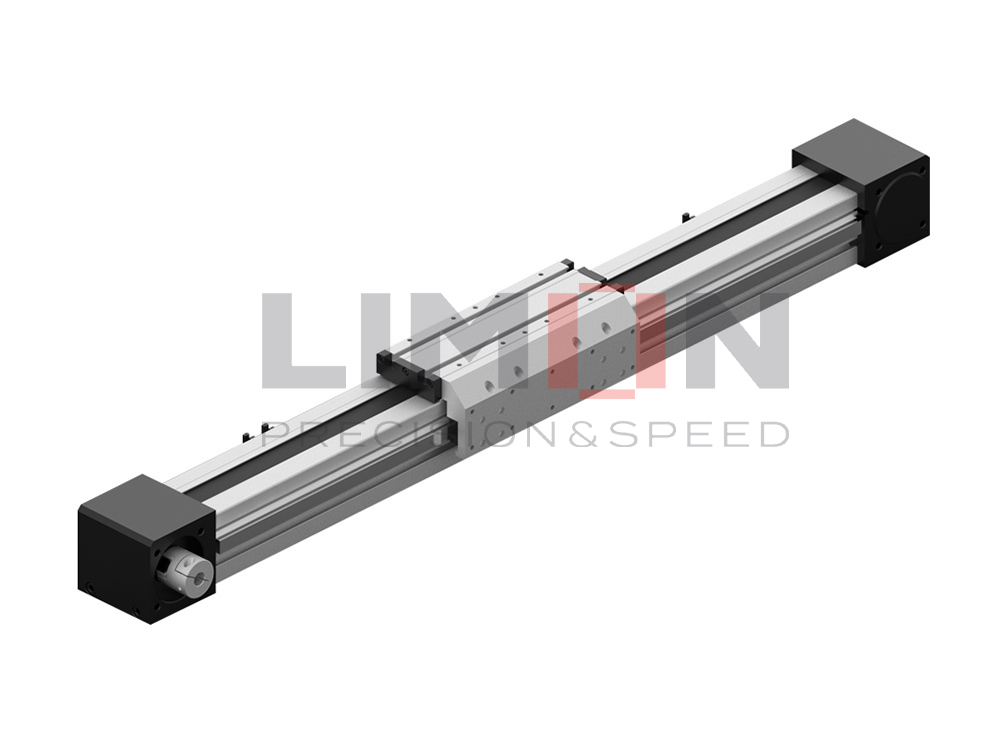

GTC Belt-Driven Linear Actuators

Overview

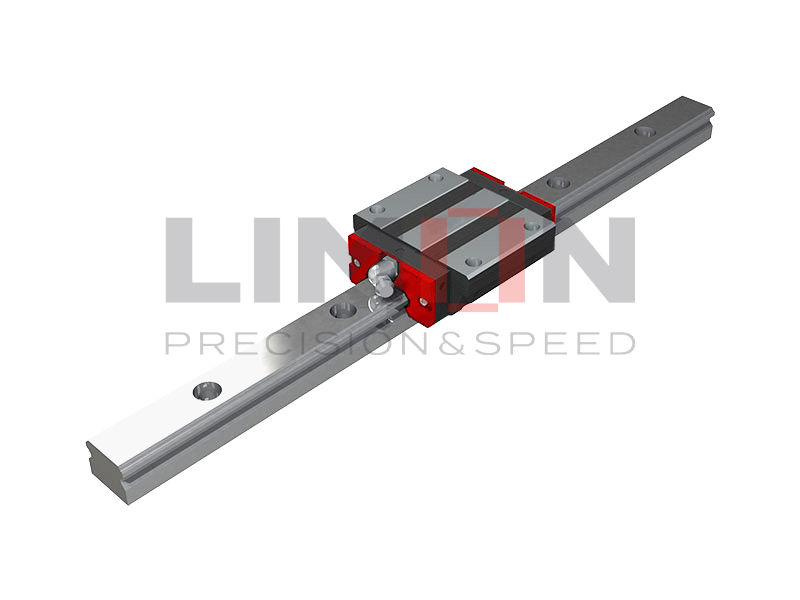

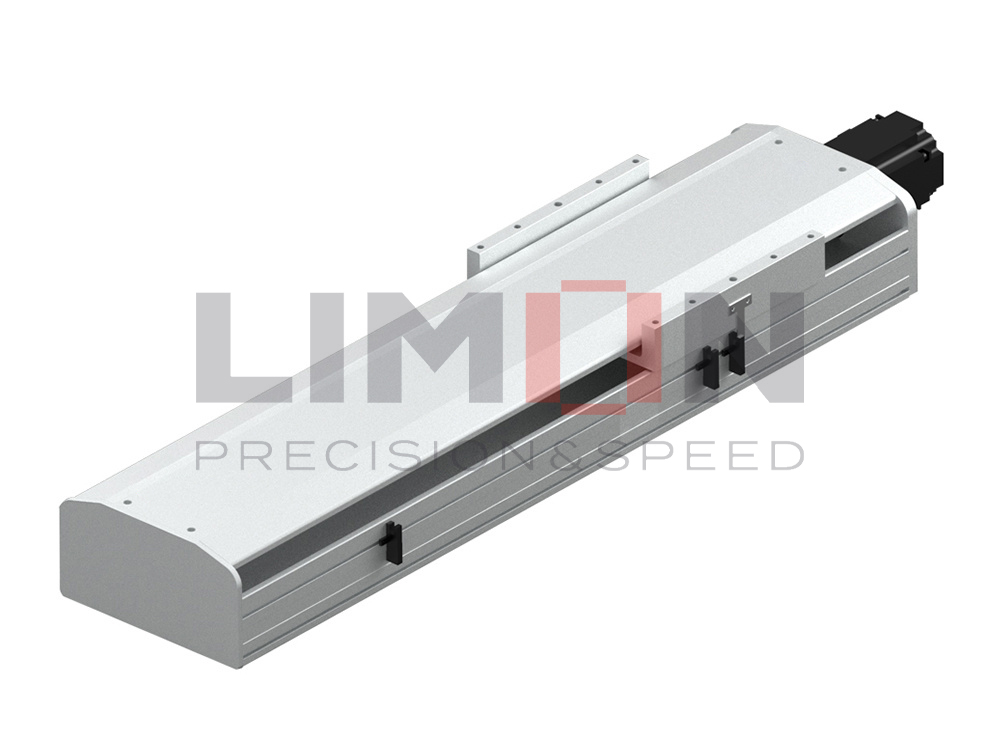

The GTC series are belt-driven linear actuators specialized in long-stroke and high-speed automation scenarios, featuring an embedded guideway fully-closed structure. They break through traditional stroke limitations via innovative splicing technology, combining high cost-effectiveness to become an ideal choice for industrial automation.

Basic Info

- Type: Belt-driven (open/fully-closed type)

- Repetitive Accuracy: ±0.05mm

- Single Unit Max Stroke: 4,000mm; up to 12,000mm with splicing

- Maximum Speed: 5,000mm/s

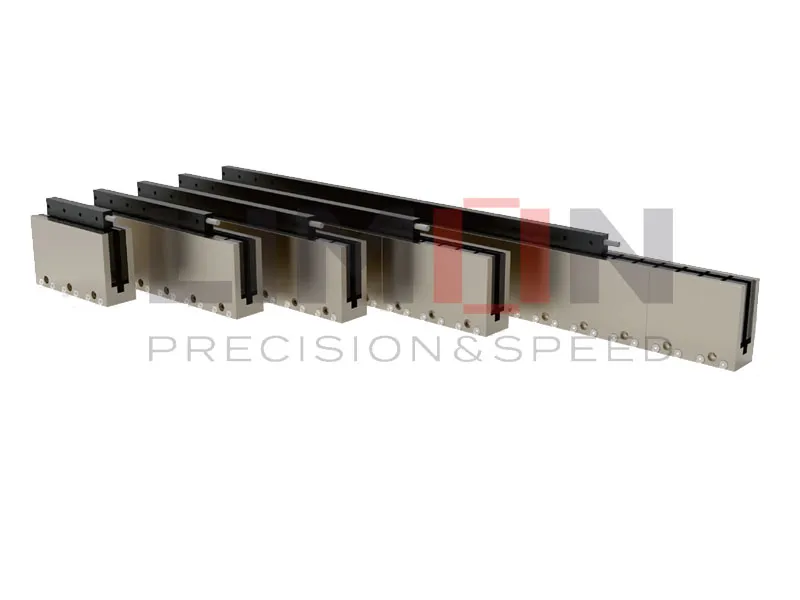

- Main Material: Lightweight aluminum alloy, supporting multi-axis combined applications

- Belt Types: PU belts (low-dust, suitable for cleanrooms) / rubber belts (low-noise, suitable for general environments)

Characteristics

- Long Stroke & High Speed: Designed with a single-unit 4m stroke, splicing technology solves straightness issues for ultra-long strokes; 5,000mm/s high-speed operation adapts to fast sorting and handling scenarios.

- Low Maintenance: High-tension steel belts require only initial adjustment; external oil injection holes support maintenance-free lubrication, and pulleys use maintenance-free ball bearings.

- Space-Optimized Design: Integrated pulley and coupling shorten lateral motor installation length; multi-directional motor mounting (left/right/up/down folding) adapts to complex mechanical layouts.

- Environmental Compatibility: PU belt versions meet cleanroom standards, while rubber belt versions suit high-dust or general industrial environments.

Industry Applications

- Photovoltaic Industry: Wafer sorting, photovoltaic module inspection equipment

- Lithium Battery Manufacturing: Cell assembly lines, electrode coating transmission systems

- White Goods Production: Large-component automated assembly lines

- LCD Panels: Roll-to-roll panel transportation and positioning

- General Automation: Packaging machinery, logistics sorting systems

.jpg)