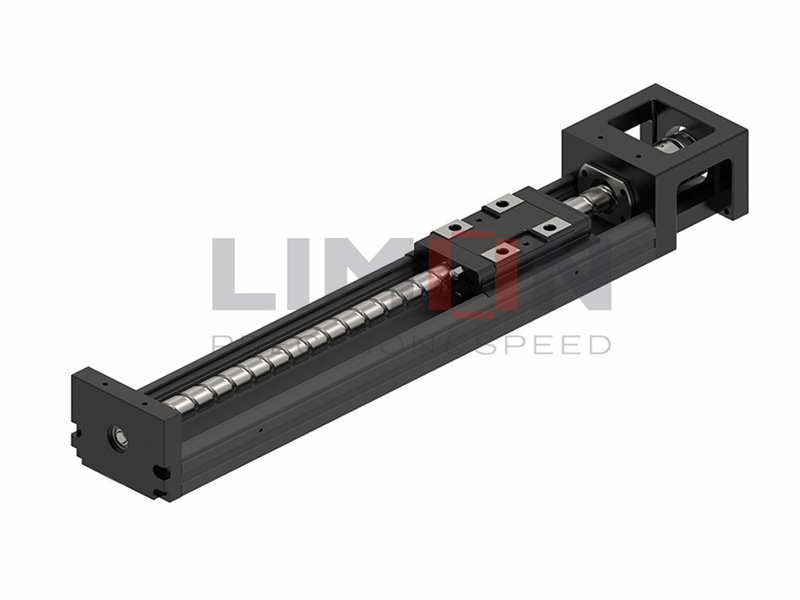

Roller rail guides, which use cylindrical or barrel-shaped rollers instead of spherical balls for the load–bearing elements, are typically associated with machine tool applications. But the performance benefits that rollers bring to machining centers can be worthwhile in other applications as well. If you’re designing a machine or system that requires linear motion, consider these three advantages that roller rail guides offer.

1. Higher load capacity

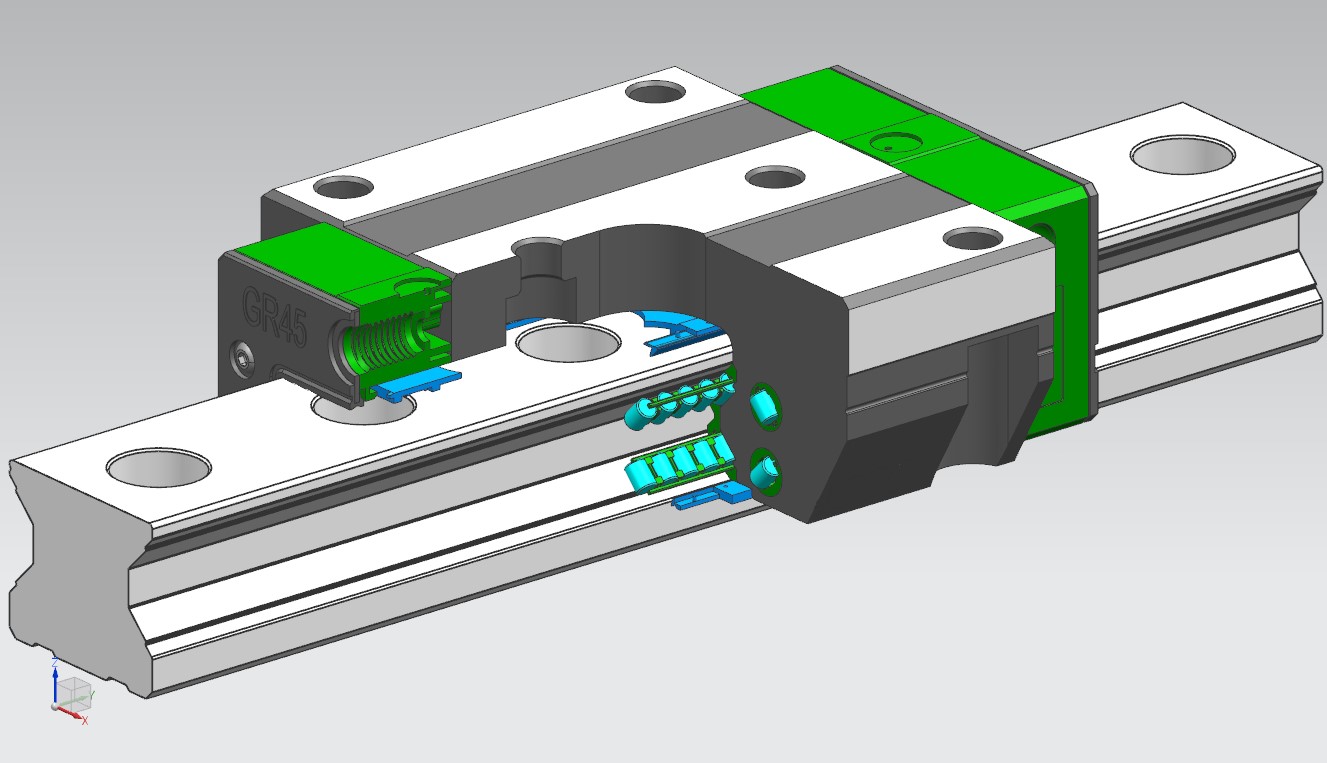

When subjected to a load, rollers form line contact with the guide surface, which is much larger than the point contact that is formed when balls are subjected to a load. This gives roller rail guides higher load capacities than ball rail guides of the same size.

This higher load capacity is further amplified by the bearing life equation for rollers. Rather than being raised to the 1/3 power, as with ball rail guides, the life equation for roller rail guides is raised to the 10/3 power, which means that even a small premium in load capacity for a roller bearing versus a ball bearing translates to a much higher travel life for the roller version.

2. Ability to downsize

The higher load capacity and longer life of roller bearings mean that designers can often use roller bearings that are one or two sizes smaller (for example, size 25 rather than size 45) than the ball bearings that would be needed to achieve same travel life.

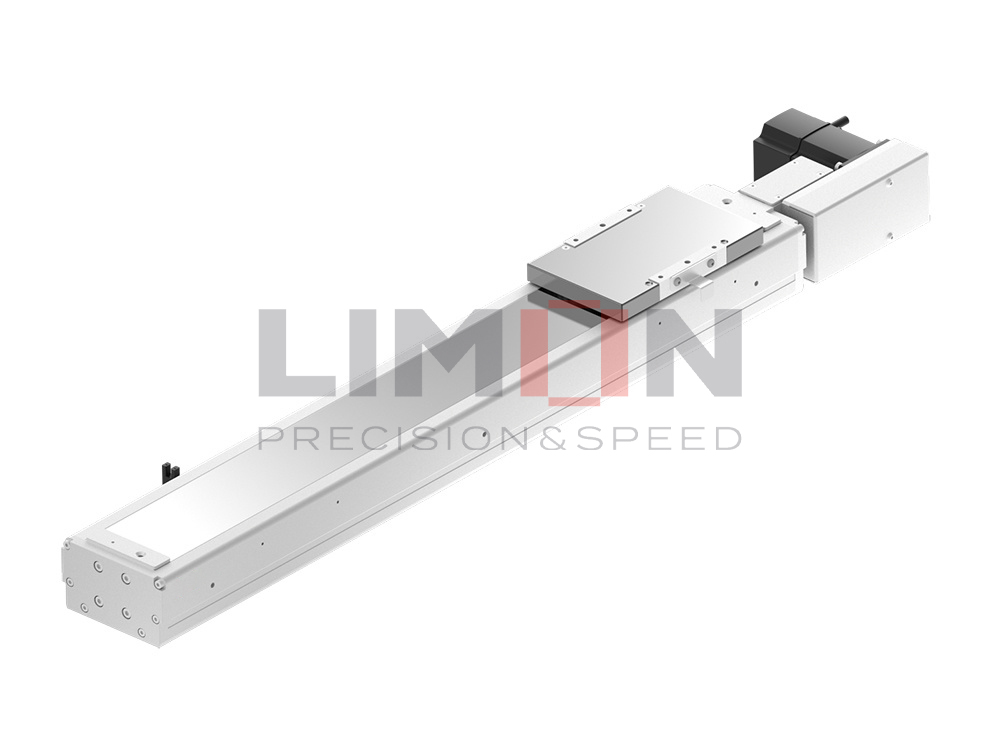

This downsizing of the linear bearings can be especially beneficial in multi-axis or gantry applications, where weight saved on one axis has a trickle-down effect on the supporting axes, potentially saving tens of thousands of dollars in component costs.

In a three-axis Cartesian or gantry system, reducing the mass of the Z axis reduces the static and dynamic forces on the Y axis, which means that the Y axis can potentially be downsized. Likewise with the X axis – by reducing the mass of the Y and Z axes, it may be possible to downsize the X axis, since the forces acting on it are reduced. And this downsizing applies not only to the linear guides, but also to the drive mechanism (linear motor, ball screw, etc.), motor, and other components such as couplings, gearboxes, and cable carriers. This provides savings in material cost, energy usage, and space.

3. Higher rigidity

The line contact formed by rollers also provides higher rigidity than the point contact formed by balls, which is the primary reason that roller rail guides are so widely adopted in machine tools. However, Jason Winburn, Application Engineer at Bosch Rexroth, points out that printing processes that involve pressing, such as flexographic printing and narrow web printing, also benefit from the rigidity of roller rail guides. Less deflection of the guide block means less deflection of the printing head, resulting in a higher quality print.

Spangler sees customers in the woodworking industry who use roller rail guides for their higher rigidity, especially in processes with high shock loads, such as veneering. He also points out that sealing is even more critical for roller rail guides than for ball rail guides. This is because in a ball rail guide, the balls can push debris to a location outside the contact zone, since the balls only have point contact with the raceway. But the line contact that rollers form with the raceway leaves nowhere for the debris to go that will be outside the load zone, so any amount of debris that makes its way into the bearing will affect life and performance.