1. Precision and Tolerance Requirements:

The level of precision and tight tolerances required for a specific application directly influences the cost of ball screws. High-precision ball screws, designed for applications demanding minimal backlash and exceptional accuracy, often come with a higher price tag due to the stringent manufacturing processes involved.

2. Material Selection:

The choice of materials used in the construction of ball screws plays a significant role in determining their cost. High-quality materials, such as hardened steel or stainless steel, can contribute to increased durability and performance but may also result in higher manufacturing costs.

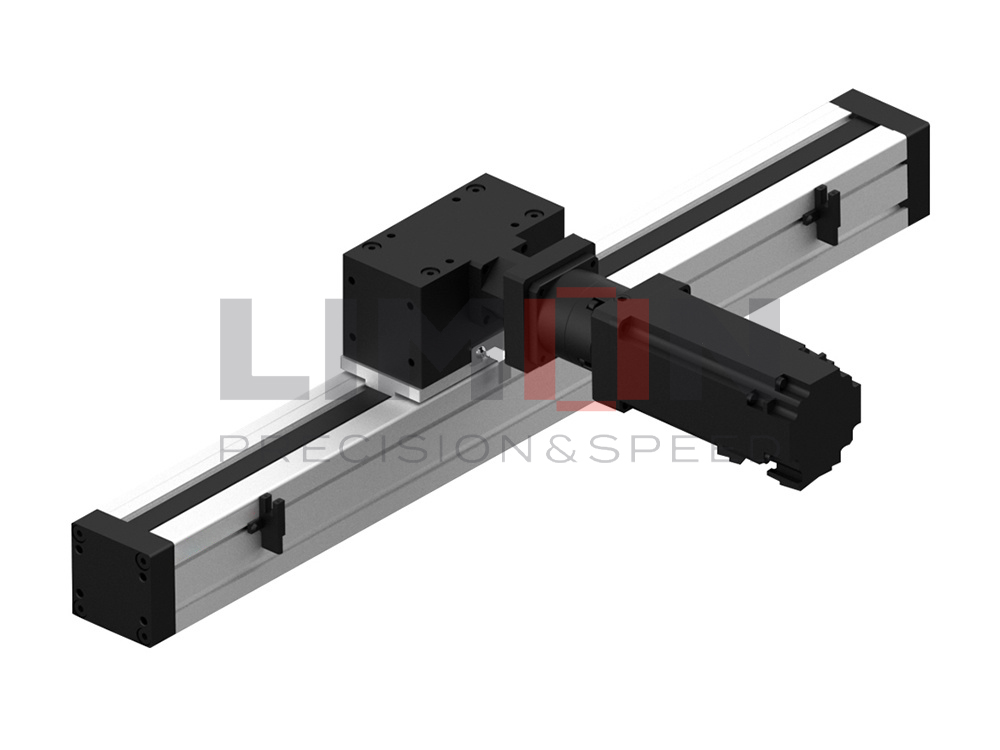

3. Manufacturing Complexity:

The complexity of the ball screw design and the manufacturing processes involved impact the overall cost. More intricate designs and advanced manufacturing techniques, such as precision grinding and heat treatment, can contribute to higher production expenses.

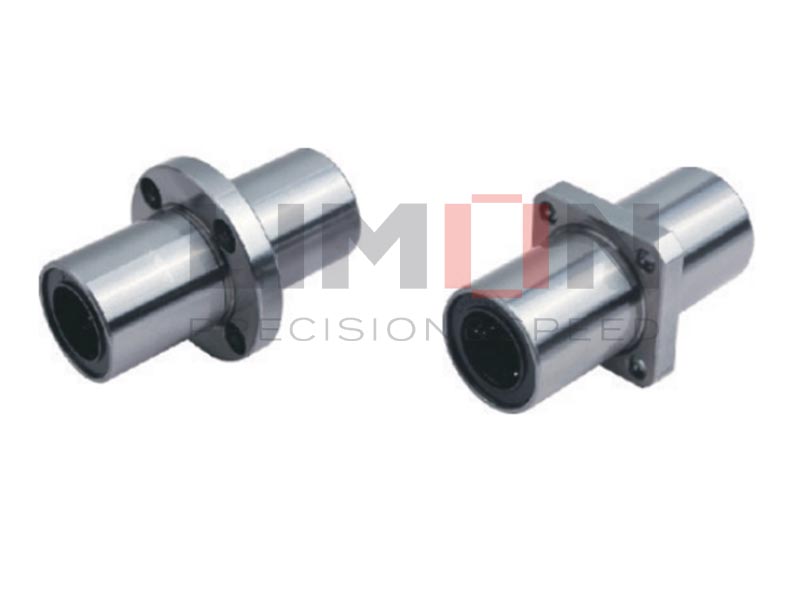

4. Lead Accuracy and Nut Style:

The lead accuracy of a ball screw, which relates to how precisely it can move over a specified distance, affects its cost. Additionally, the choice of nut style, whether it’s a standard nut or a more advanced design like a preloaded or flanged nut, can influence the overall price.

5. Coating and Surface Treatments:

Certain applications may require specialized coatings or surface treatments to enhance the performance and longevity of ball screws. These treatments, such as corrosion resistance coatings or special lubricants, can contribute to an increase in cost.

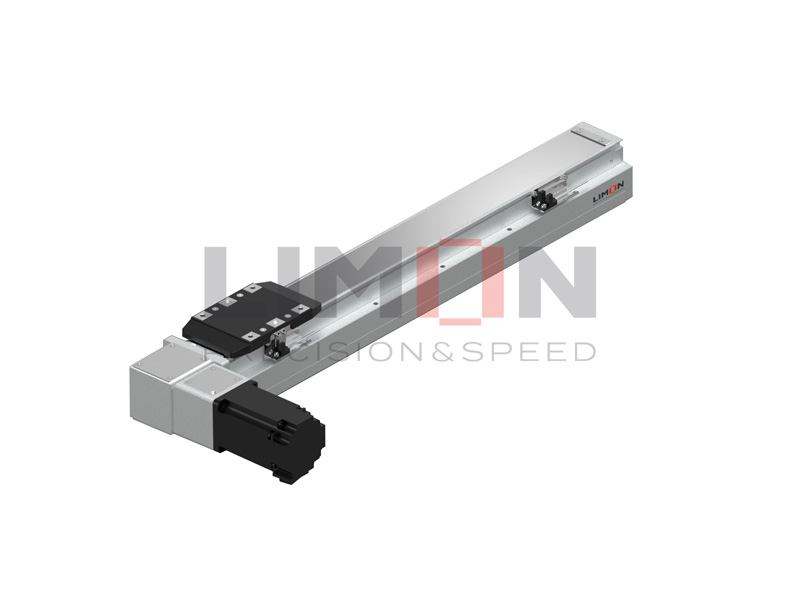

6. Size and Length:

The physical size and length of a ball screw impact the amount of material needed for its construction. Larger or longer ball screws may incur higher material and manufacturing costs, contributing to an elevated overall price.

7. Brand Reputation and Quality Assurance:

Established brands with a reputation for high-quality products and rigorous quality control processes may offer ball screws at a premium price. Customers often place value on reliability and consistency when selecting ball screws for critical applications.

8. Customization Requirements:

Customized ball screws tailored to specific application requirements may involve additional engineering and manufacturing efforts, contributing to a higher cost compared to off-the-shelf options.

In conclusion, the cost of ball screws is influenced by a combination of factors, including precision requirements, material selection, manufacturing complexity, lead accuracy, coating options, size, brand reputation, and customization needs. Understanding these factors empowers decision-makers to make informed choices based on the unique demands of their applications while balancing performance and budget considerations.