1. Higher Efficiency:

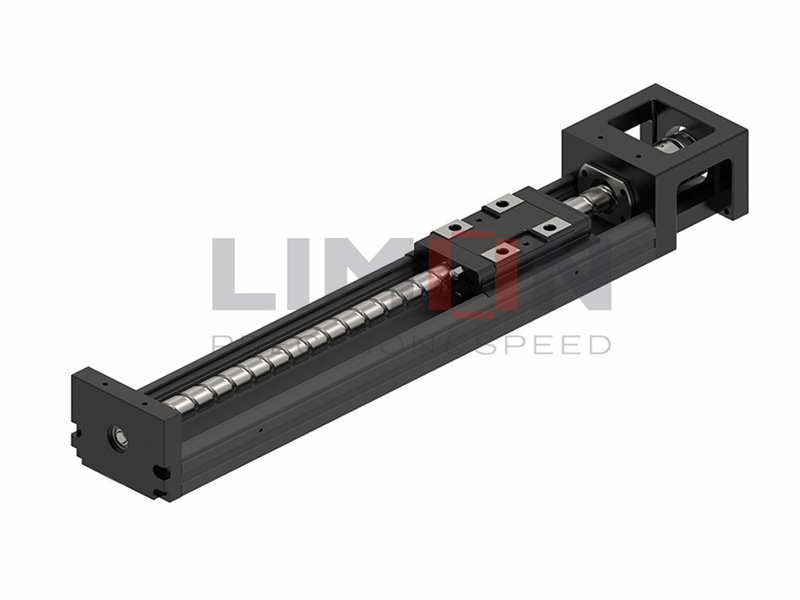

Ball Screws: Ball screws feature rolling elements, such as ball bearings, that circulate within the helical groove of the screw. This rolling motion reduces friction significantly, resulting in higher mechanical efficiency. As a result, ball screws require less input power to achieve the same linear motion as traditional screws.

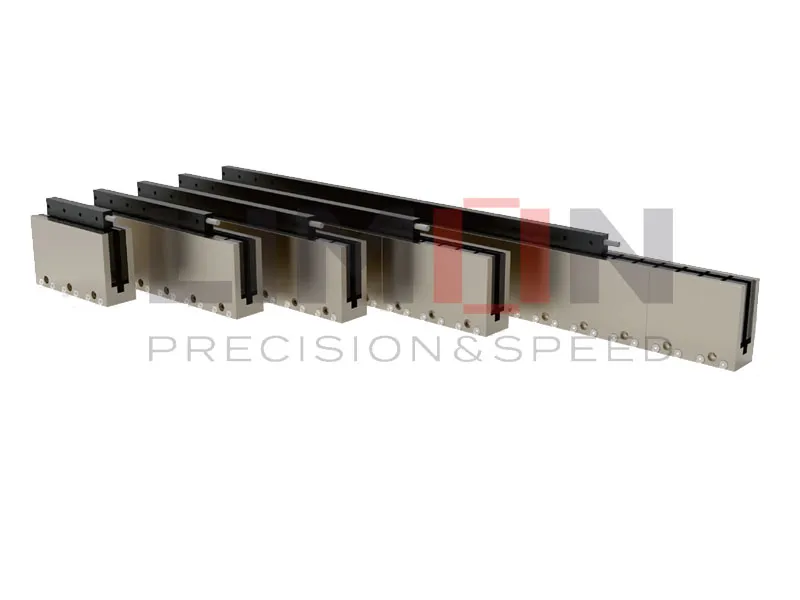

Traditional Screws: Traditional screws typically rely on sliding friction between threads, leading to higher resistance and lower efficiency. The sliding contact generates more heat, and the overall efficiency of traditional screws tends to be lower compared to ball screws.

2. Precision and Repeatability:

Ball Screws: The circulating ball bearings in ball screws contribute to smoother and more precise linear motion. This characteristic makes ball screws ideal for applications where accuracy and repeatability are critical, such as in CNC machinery and robotics.

Traditional Screws: Traditional screws may exhibit more significant backlash, resulting in less precise movement. Backlash refers to the clearance between the screw and nut, and minimizing it is crucial for achieving accurate positioning.

3. Reduced Backlash:

Ball Screws: The design of ball screws inherently minimizes backlash. The rolling motion of the ball bearings and the helical groove contribute to a more direct and responsive transfer of motion, reducing the clearance between the screw and nut.

Traditional Screws: Traditional screws often have more substantial backlash due to the sliding contact between threads. This clearance can lead to imprecise positioning and decreased accuracy in applications that demand tight tolerances.

4. Enhanced Speed and Acceleration:

Ball Screws: The reduced friction in ball screws allows for higher speeds and accelerations without sacrificing precision. This makes ball screws well-suited for applications requiring dynamic and rapid movement.

Traditional Screws: Higher friction in traditional screws may limit the achievable speeds and accelerations. The sliding contact between threads can result in more wear and heat generation, affecting overall performance.

5. Longevity and Maintenance:

Ball Screws: The rolling motion in ball screws reduces wear and tear, contributing to a longer lifespan. Additionally, ball screws often require less frequent maintenance compared to traditional screws.

Traditional Screws: The sliding contact in traditional screws may lead to increased wear over time, requiring more regular maintenance and replacement of components.

The advantages of ball screws over traditional screws, including higher efficiency, precision, reduced backlash, enhanced speed, and longevity, make them a preferred choice in numerous industrial applications. Understanding these benefits empowers engineers and designers to make informed decisions when selecting the most suitable motion control solution for their specific needs.