Enduring high load or harsh conditions reduces bearing life, causing unexpected failures and expensive downtime. Proper life calculations and maintenance strategies can prevent these issues and optimize system longevity.

Calculating the life of linear roller bearings involves evaluating dynamic load ratings, contact stress, shaft hardness, corrosion factors, and operational conditions to predict service intervals accurately.

Let’s explore the fundamentals behind bearing life prediction and how to maximize performance.

Understand, Calculate, and Retain the Life of Your Linear Roller Bearings

Estimating bearing life starts with understanding the dynamic load rating (C), the equivalent dynamic load (P), and basic life formula:

L10=(CP)p×106L_{10} = \left(\frac{C}{P}\right)^p \times 10^6 revolutions,

where exponent p is 3 for roller bearings.

For example, a bearing with C = 10 kN and P = 4 kN yields:

L10=(10/4)3×106≈15.6×106L_{10} = (10/4)^3 \times 10^6 ≈ 15.6 \times 10^6 revolutions.

To convert revolutions into hours:

L10h=L10(rpm/60)L_{10h} = \frac{L_{10}}{(rpm/60)}.

At 600 rpm:

L10h≈15.6×10610=1.56×106L_{10h} ≈ \frac{15.6×10^6}{10} = 1.56×10^6 hours—an unexpectedly long lifespan under proper conditions.

Real‑world life is affected by lubrication, contamination, misalignment, and load variations. Engineers apply a life modification factor (a₁–a₄) to estimate more realistic life expectancy.

Regular lubrication, accurate mounting, and contamination control help retain bearing life near its theoretical rating.

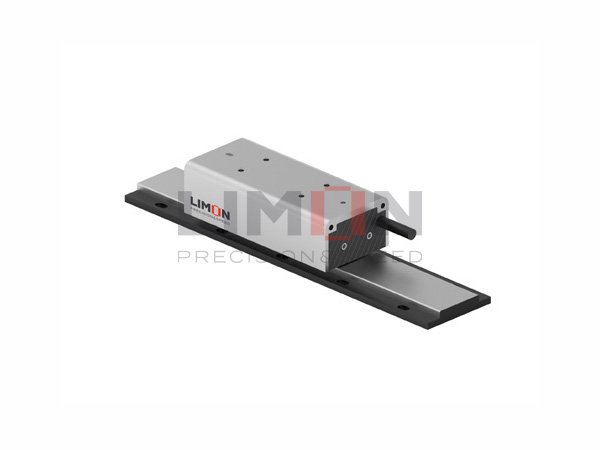

Single- and Double-Row Roller Bearings in Linear Motion

Linear roller bearings come in single‑row and double‑row configurations, each with unique life characteristics:

Single‑row bearings handle moderate loads and allow compact, cost‑effective designs. Their life is calculated using the basic L₁₀ formula with p = 3.

Double‑row bearings can carry higher radial loads and moments. Life is estimated using the combined equivalent dynamic load on both rows:

P=X⋅Fr+Y⋅FaP = X \cdot F_r + Y \cdot F_a,

where X és Y are load factors—and p remains 3.

Double‑row designs spread the load across more rolling elements, boosting life expectancy and stiffness. Yet, predictability requires precise alignment, proper preload, and well‑balanced lubrication strategies.

Understanding the nuances between single‑ and double‑row systems enables accurate life calculation and better selection for your application.

Shaft Hardness and Linear Bearing Life

The hardness of the mounting shaft significantly influences the life of linear roller bearings. Hard shafts resist scuffing, indentation, and surface fatigue, directly affecting bearing longevity.

Typical requirements:

Hardened shafts: ≥ HRC 58

Case‑hardened shafts: ≥ 60 HRC surface, 40 HRC core

Without sufficient hardness, rollers imprint on the shaft’s grooves, forming permanent dents and accelerating fatigue flaking. This reduces effective life far below the L₁₀ rating.

Additionally, shaft surface finish—with roughness Ra ≤ 0.2 μm—reduces friction heat and prevents micro‑pitting. Proper shaft specification enhances reliability and ensures that bearing fatigue life remains governed by dynamic load calculations, not substrate deformation.

Minimize Corrosion and Maximize Life

Corrosion is a silent killer of linear roller bearings. Even slight oxidation or chemical exposure can break the lubricant film, add abrasive particles, and accelerate wear.

Key anti-corrosion strategies:

Use stainless steel, chrome-plated, or corrosion-resistant coatings for races and rollers.

Select lubricants with rust inhibitors.

Seal bearing units with wipers, shields, or labyrinth covers to block moisture and dust.

Install in controlled environments or use desiccant or pressurized air purging.

Establish proactive maintenance routines: inspect seals, relubricate, and monitor surface condition.

By reducing contamination and corrosion, bearings maintain life predictions based on fatigue calculations, rather than failing due to premature surface damage.

Összefoglaló

Calculating and preserving linear roller bearing life relies on load rating, shaft hardness, lubrication, contamination control, and corrosion prevention—ensuring reliable, long-lasting performance.További kérdésekkel forduljon a következő címre sales@limonrobot.com