Core Performance Demands of Linear Guideways Across Industries

Different industries impose varying and often stringent demands on linear motion products, especially linear guideways. In the automation industry, for example, reliability, speed, and maintenance-free operation are paramount. Automotive assembly lines demand high load-bearing capabilities and consistent precision over extended operational periods. Meanwhile, semiconductor fabrication prioritizes sub-micron positioning accuracy and ultra-clean operational standards due to contamination sensitivity.

Medical device manufacturing requires both corrosion resistance and silent operation to meet regulatory and user environment constraints. Food and beverage industries need linear guides constructed from stainless steel or with specialized coatings, designed to endure aggressive washdowns and adhere to hygiene standards. Each industry thus compels linear guide manufacturers to offer bespoke features—ranging from compactness and durability to chemical resistance and long-term cost efficiency—driving the necessity of targeted selection.

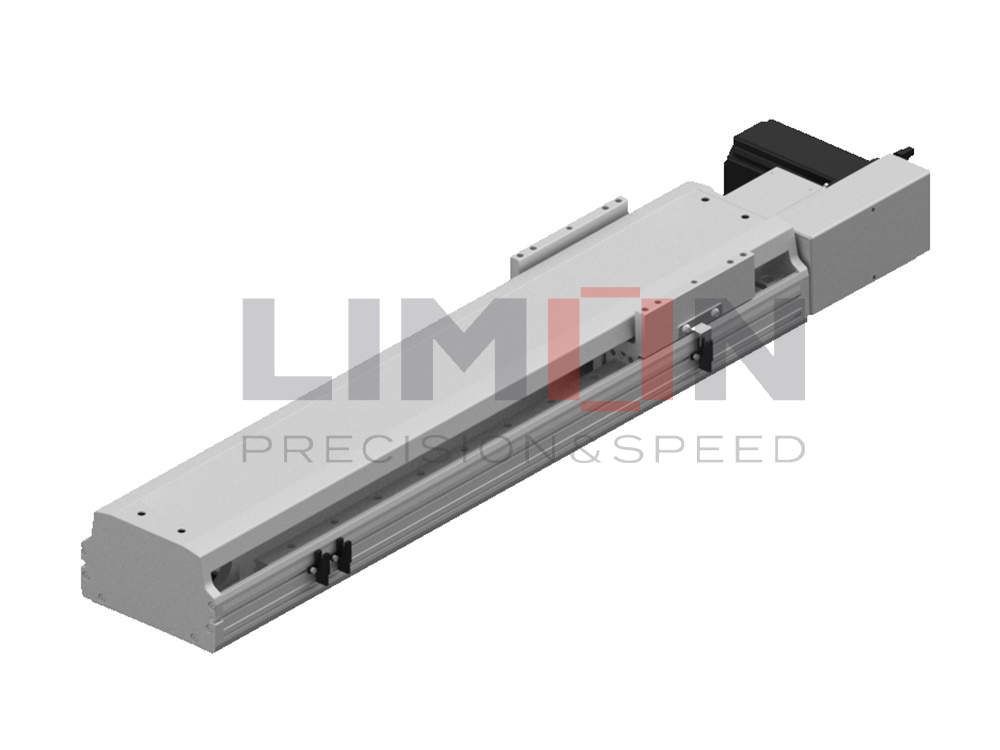

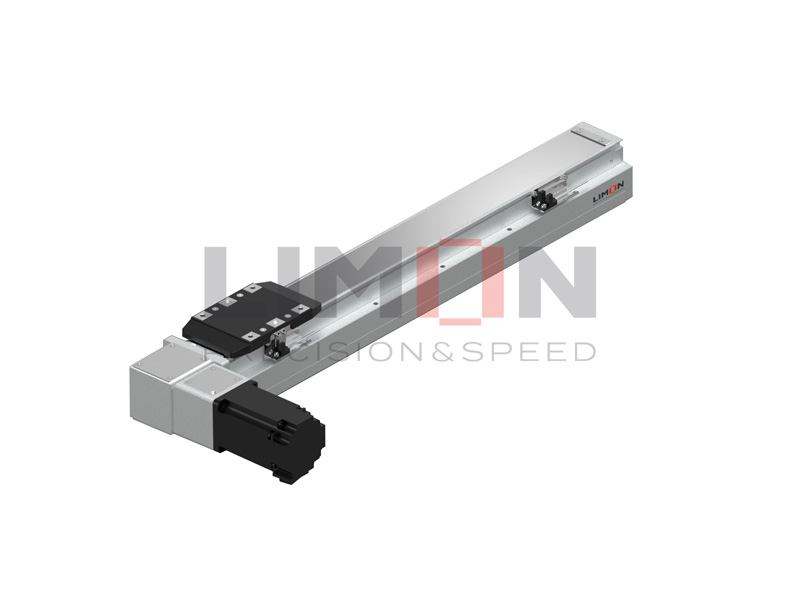

LIMON, a notable player in the field, offers diverse linear guideway solutions engineered to meet these specific sectoral requirements. Their modular designs and advanced materials provide scalable performance across a broad spectrum of operational conditions.

Match load, speed, and accuracy requirements qualitatively to avoid overengineering. Choose guides based on real-world duty cycles, not peak ratings.

A critical yet often overlooked principle in selecting linear guideways is aligning specifications with the application’s actual operating parameters. Engineers are frequently tempted to overdesign by focusing solely on peak load, maximum speed, or theoretical accuracy. This approach leads to unnecessarily large and expensive components that contribute little to performance but increase cost and inertia.

Instead, guide selection should reflect real-world duty cycles, including average operational loads, typical travel speeds, and functional tolerances. For example, in applications where brief high-speed bursts occur, it’s often more effective to select a guide that performs consistently under normal usage rather than targeting rare peak events. This strategy ensures system reliability, reduces material and energy consumption, and simplifies integration into compact assemblies.

Modern linear motion products like those offered by LIMON are developed with modular adaptability in mind, allowing engineers to select appropriately scaled systems without compromising safety or performance.

Cognitive Biases Common in Linear Guide Selection

In linear guideway selection, several cognitive biases often distort decision-making. One prevalent bias is the assumption that larger components automatically equate to better performance. This misconception ignores critical factors like load distribution, mounting surface precision, and structural support. A smaller, correctly installed guide may outperform a larger, poorly supported one in both longevity and stability.

Another common mistake is overreliance on static datasheet values while ignoring dynamic conditions such as vibration, impact, and thermal expansion. Misinterpreting technical data, or applying ideal laboratory test values to real-world environments, can result in premature failure or suboptimal motion control.

Users also tend to overlook system-wide interdependencies—believing the linear guide alone dictates performance—when in reality, the overall design, including mounting quality and adjacent components, plays a decisive role.

Ultimately, sound decision-making stems from understanding the complete application context. This includes environmental stressors, operational frequency, alignment constraints, and maintenance expectations. Proper education and collaboration with experienced linear guide manufacturers can bridge the knowledge gap and lead to smarter, more reliable system designs.

Avoid hasty choices—understanding your application’s nuances can prevent costly redesigns. Read on to see how industries do it right.

Case-Based Analysis of Linear Guideway Selection in Key Industries

1.Machine Tools: Addressing Vibration Due to Insufficient Rigidity

Machine tool operations often require precise, high-load movement. A common pitfall is underestimating the structural rigidity needed to suppress vibration during dynamic cutting processes. Inadequate rigidity in linear guideways not only leads to vibration but also results in poor surface finishes, tool wear, and inconsistent machining tolerances.

To combat this, engineers can opt for wider rail sizes or dual-rail configurations from established linear guide manufacturers like LIMON. Additional enhancements such as higher preload levels and reinforced mounting bases significantly reduce deflection. LIMON’s high-rigidity series is especially designed for such environments, offering optimized rail geometries and cage designs that resist torsional loads while improving motion stability under heavy-duty usage.

Combining vibration dampening technologies and real-time feedback systems, these solutions ensure better process consistency and extend the service life of both tools and the guideways.

2.3D Printing: Balancing Lightweight Design and Repeatability

3D printing systems demand a fine balance between structural lightness and precision. Heavy guideways can increase inertia, slowing down motion response and compromising print quality, especially at high speeds. However, overly light designs may suffer from backlash or poor repeatability, resulting in defective parts.

LIMON’s compact linear motion products, which feature hollowed carriage bodies and low-friction polymer cages, are optimized for additive manufacturing platforms. These systems reduce weight without sacrificing alignment stability. Repeat positioning accuracy is achieved through precision-ground raceways and consistent preload applications.

Furthermore, many 3D printers benefit from integrating LIMON’s miniature series guideways, which allow for reduced envelope size and increased platform flexibility. This results in enhanced mechanical response during rapid direction changes, crucial for maintaining fidelity in fine-layer resolution.

3.Warehouse Automation: Durability Under High-Cycle Usage

Logistics and warehouse automation systems often operate 24/7 under high-frequency loads. The repetitive nature of linear travel—often across extensive distances—demands guideways that maintain performance without excessive lubrication or maintenance downtime.

Durability testing of LIMON’s linear guideways under simulated warehouse conditions reveals high resilience to repetitive mechanical stress. Key design attributes, such as hardened steel raceways, anti-corrosion coatings, and double-sealed end caps, contribute to long-lasting performance even in dusty or vibration-prone environments.

Additionally, these guideways integrate seamlessly with belt drives and robotic arms. When used in conjunction with predictive maintenance software, operators can monitor wear patterns in real-time and preempt failures. This minimizes operational interruptions while maximizing throughput across automated warehouse systems.

4.Medical Devices: Dustproofing for Sterile Environments

Medical devices—especially those operating in surgical or diagnostic environments—require linear guides that not only perform with high accuracy but also resist particulate emission. Sterility, noise levels, and chemical compatibility are all decisive selection factors.

LIMON offers linear motion products featuring full-contact seals, low-outgassing lubricants, and stainless steel components to ensure compatibility with autoclave cleaning and disinfection cycles. Their dustproof designs incorporate multiple wiper layers and internal channeling to isolate and expel particulates.

In environments where precision scanning or robotic surgery is conducted, these features prevent microscopic contamination and support quieter operation. Furthermore, LIMON’s lubrication-free and polymer-based guideways are preferred where maintenance access is restricted or downtime must be minimized.

Conclusion

Smart guideway selection avoids costly errors—evaluate by real usage, not assumptions, and tailor choices to each industry’s needs.