LIMON Linear Motion Products: ball screw

Basic info of LIMON ball screw

Specification of LIMON ball screw

Ball screw is the most commonly used transmission component in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion or to convert torque into axial repetitive force,which is high precision,reversibility and high efficiency. Due to the small frictional resistance, ball screw are widely used in a variety of industrial equipment and precision instruments. The ball screw is composed of screw, nut, steel balls, preloading piece, deflector and dust-proof end seals.

LIMON is the leading supplier of linear components. In order to meet customer’s demands, we are always keeping the pace of making innovations and developing new products and technical reformation. Since 2003, we started from linear bushing. With the customer and market demands developed, we started to produce the linear guide and ball screw, which are also our company’s main products currently. And today I am also going to share more about LIMON ball screw.

Basic info of LIMON ball screw:

Regarding the ball screw, LIMON could produce both rolled and grinding type, and precision can up to C3. Our size from 06 to 80mm, with left and right turning, double nut also available.

Features of LIMON Ball Screw:

-

High Reliability

LIMON applies stringent quality control standards on every production process. With proper lubrication and use, trouble-free operation for an extended period of time is possible.

-

Smooth Operation

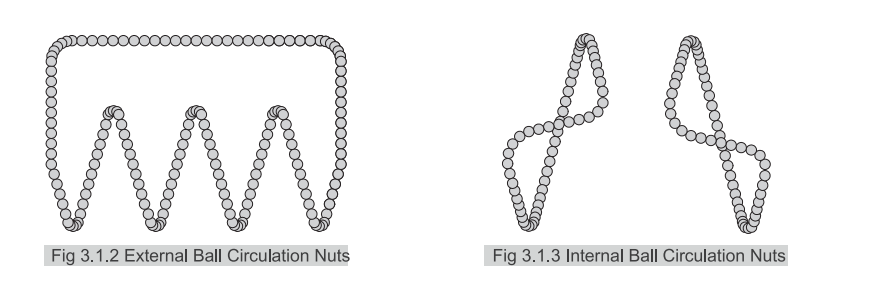

The high efficiency of ball screw is vastly superior than conventional screws as shown in Fig 3.1.1.It takes less than 30% torque to make the linear motion into rotary motion.

-

High Rigidity and Preload

The ball screw of LIMON is designed with Gothic arch groove, which makes the screw easy to rotate even using minimum axial play. To make the rigidity more appropriate to using condition, you can change the preload between one or two screw nuts to reduce axial play.

-

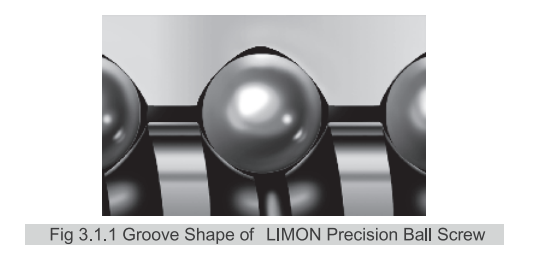

Circulation Method

5.High Durability

Specification of LIMON ball screw:

SFU - high load ball screw type: small lead, low speed applications

SFS - quiet ball screw type: Linear unit, electronic industry, high speed handling application.

SFY - high speed ball screw type: suitable for industries which required ball screw maximum speed can reach a high level.

And LIMON can also provide the SFK, SFI, SFA, DFU, DFI series nut.

Main parameters of ball screw:

1. Ball screw diameter: Common specifications are 06, 12, 16, 20, 25, 32, 40, 50, 63, 80. Nominal diameter and load are basically proportional to the larger the diameter of the load

2. Lead: Refers to the distance the nut moves in a straight line once the screw is rotated. Common leads are (unit: mm) : 2, 4, 5, ,10, 16, 20, 25, 32, 40. The parameters related to the lead are the speed of the nut and the linear thrust provided by the ball screw. At the same speed, the larger the lead, the ball screw maximum speed higher.

So which factors will affect the ball screw maximum speed? Actually, except the lead, the ball screw maximum speed also related to the diameter of the ball screw, the form of processing and precision grade, quality, etc. But the main thing is the lead, which directly determines the velocity. Another influence on the ball screw maximum speed is the size of the external driving force, which is related to the motor used. Under the same lead, the higher the motor speed, the higher the screw speed.

3. Length: There are two concepts, one is full length, the other is thread length. Thread length also has two parts, one is the length of the thread, one is the effective stroke, the former refers to the total length of the thread part, the latter refers to the theoretical maximum length of the nut straight line movement.

4.Nut type: SFU, SFS, SFY, SFA, SFK, and also the double nut, like DFU, DFI.

5.Precision:

LIMON has both rolled type ball screw (C7) and grinding type ball screw.( C5, C3)

6.Preload: The higher the preload grade, the tighter the nut and screw fit; Conversely, the lower the grade, the looser.

The principle to follow is: large diameter, double nuts, high precision, large driving torque, when the application of the screw appears above the situation, the preload grade can choose a higher point, on the contrary, choose a lower point.

After understanding the main parameters of the screw, we can select the type according to our own requirements.

LIMON involved in ball screw industry from 2007 and with professional technical and sales team, now we sell very well and has dealers in European, Asian and South American countries. Feel free to contact us, if there is any question.