Poor lubrication leads to premature linear bearing failure, causing expensive downtime and loss in production efficiency. The wrong lubricant can damage the bearing or even the entire linear system. Here’s how to make the right choice.

Choosing the right lubricant for recirculating linear bearings ensures smooth operation, minimizes wear, and extends bearing life. Key considerations include grease vs. oil, environmental factors, and lubrication intervals.

Let’s explore how to match the correct lubricant with your linear bearing system.

The Basics: Grease Or Oil?

The first decision in choosing a lubricant for linear bearings is deciding between grease and oil. Each option has its strengths and limitations depending on the application and environment.

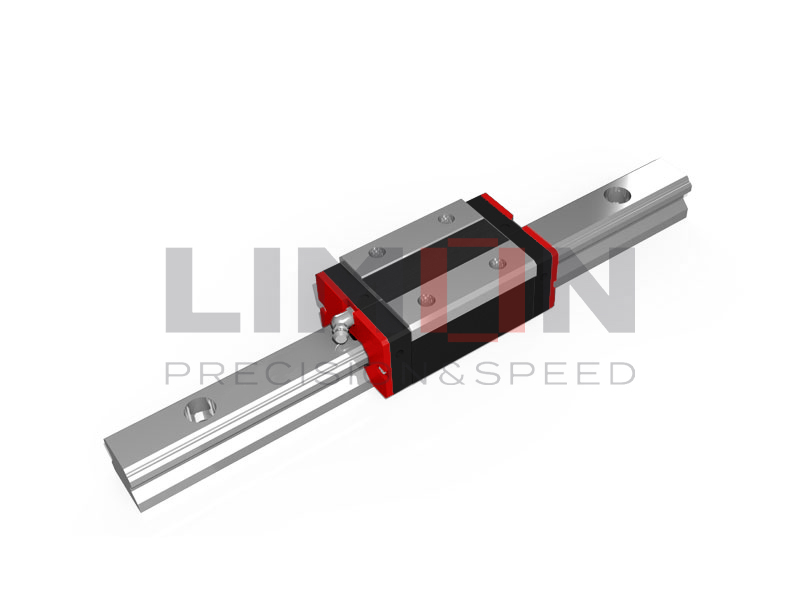

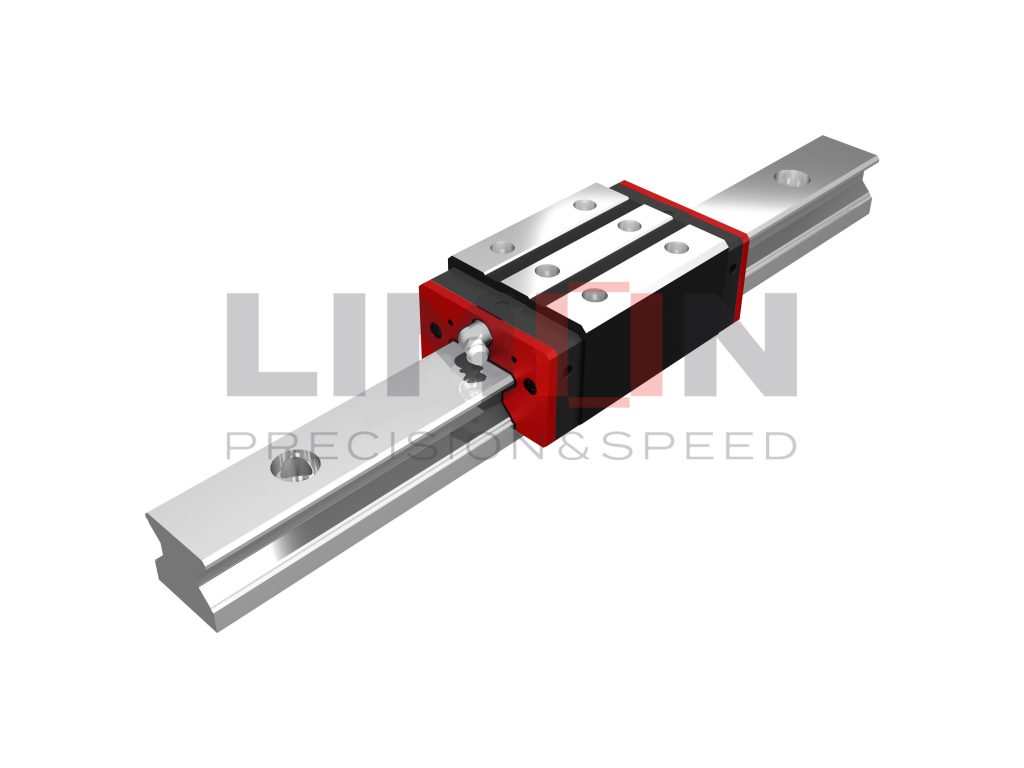

Grease is the more commonly used lubricant for recirculating linear bearings. It has a thick consistency, adheres well to surfaces, and offers long-lasting protection. Grease is particularly advantageous in applications where lubrication access is limited or in dusty environments, as it provides a protective barrier against contaminants.

On the other hand, oil provides better heat dissipation and can be advantageous in high-speed applications where minimizing friction and temperature rise is crucial. Oil is typically applied through a centralized lubrication system, allowing for consistent flow and reduced resistance.

The choice ultimately depends on operational conditions such as speed, load, environmental exposure, and maintenance capabilities. In environments prone to contamination or requiring minimal maintenance, grease is generally the preferred solution. In contrast, for high-speed, high-precision, or cleanroom settings, oil may provide better performance.

Factors For Choosing The Right Lubricant

Several key factors must be evaluated to select the optimal lubricant for recirculating linear bearings:

1. Operating Temperature

Bearings exposed to extreme temperatures—hot or cold—require lubricants that maintain viscosity across wide temperature ranges. Low-temperature environments demand lubricants that won’t thicken and restrict movement, while high temperatures call for thermally stable lubricants that resist breakdown.

2. Speed and Load

High-speed applications may require oil for reduced resistance and heat management. Conversely, high-load applications benefit from grease that maintains a thick film under pressure. The speed factor is often described as the PV value (pressure × velocity), which influences the lubricant film’s integrity.

3. Contamination Risks

Dusty, wet, or chemically aggressive environments influence the lubricant choice. Grease acts as a barrier against particles and moisture, making it suitable for harsh settings. In contrast, oil systems must include filters to ensure no contaminants are circulated with the lubricant.

4. Maintenance Access

If the bearing is hard to reach, a long-life grease is ideal, reducing the need for frequent reapplication. Systems with automatic lubrication capabilities may use oil that can be replenished consistently during operation.

5. Compatibility

Ensure the lubricant is compatible with both bearing materials and seals. Using incompatible lubricants can degrade rubber seals or cause chemical reactions that shorten bearing life.

Lubricant Selection Matrix

| Application Type | Preferred Lubricant | Key Benefit |

|---|---|---|

| High-speed machinery | Oil | Superior heat dissipation |

| Heavy-load handling | Grease | Thick film under pressure |

| Dusty/contaminated areas | Grease | Protective barrier |

| Cleanroom applications | Oil (low vapor) | Clean operation, low residue |

| Limited maintenance access | Long-life grease | Reduced service requirements |

Look To The Manufacturer For Guidance

While general guidelines provide a starting point, the linear bearing manufacturer is often the most reliable source for specific lubricant recommendations. Manufacturers conduct rigorous testing on bearing and lubricant combinations and typically publish:

Recommended grease/oil types and brands

Optimal lubrication intervals

Dosage requirements

Environmental limitations

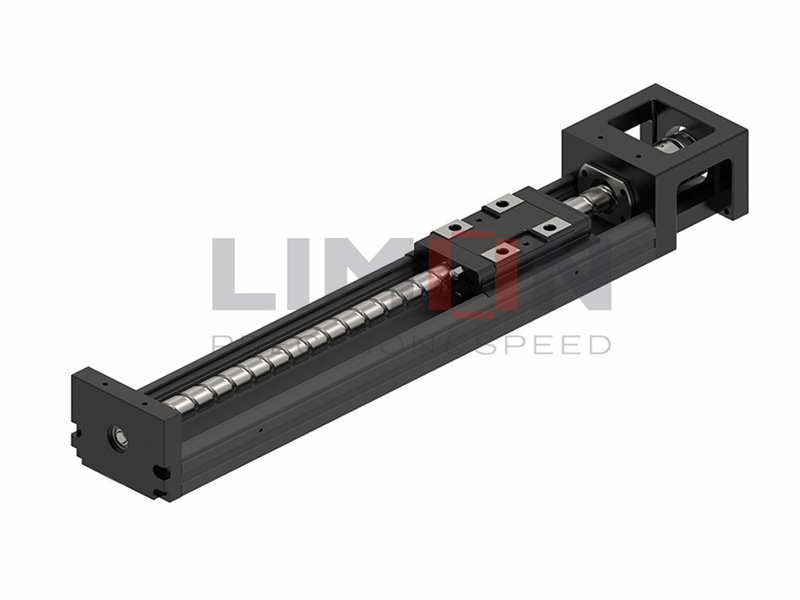

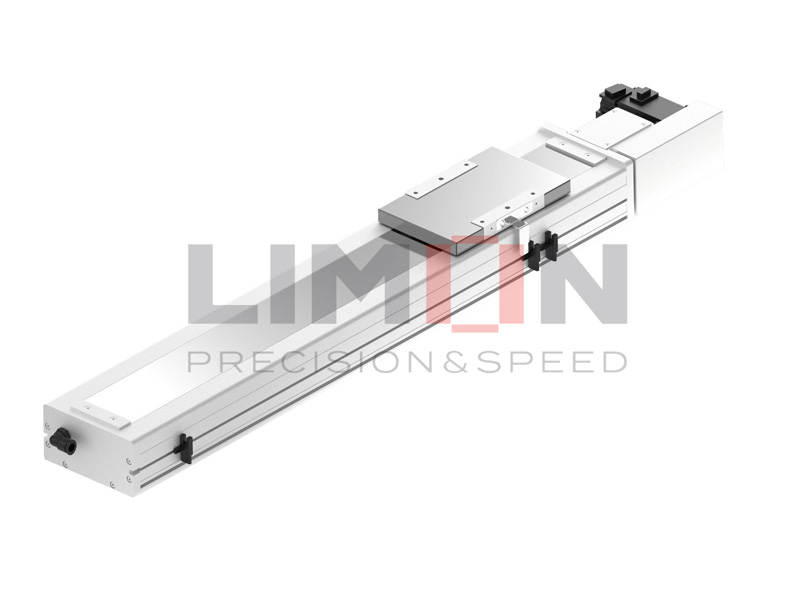

For example, LIMON linear bearings may come pre-lubricated with a specific type of synthetic grease formulated for long-life performance. Using a different lubricant—especially without consulting technical support—could lead to premature wear, void warranties, or degrade performance.

In cases where linear bearings are integrated into a larger motion system, it’s crucial to align lubricant choice with the entire assembly’s design, including shaft materials and sealing systems.

Consult technical datasheets, catalogs, or engineering support teams to match lubricant properties with operating conditions. If in doubt, reach out directly to the bearing supplier or consult case studies involving similar use cases.

How To Reduce (Or Eliminate) The Need For Re-Lubrication

Lubrication frequency is a major concern in systems operating 24/7 or in hard-to-access environments. To minimize or even eliminate frequent re-lubrication, consider the following design and maintenance strategies:

1. Self-Lubricating Linear Bearings

Some linear bearings feature integrated lubrication systems—such as oil-impregnated polymer liners or lubricant reservoirs—that slowly release lubricant over time. These systems extend intervals between re-lubrication or completely remove the need for manual greasing.

2. Lubrication Ports

Bearings with integrated lubrication ports allow for easy maintenance without disassembling equipment. A small grease nipple or oil port can be connected to a centralized system or serviced manually.

3. Long-Life Greases

Advanced synthetic greases are engineered for long service intervals and stable performance across wide temperature and speed ranges. They are especially suitable for bearings in remote, dangerous, or high-precision environments.

4. Environmental Sealing

Installing seals and wipers on linear bearings helps protect the lubricant inside and prevent contaminants from entering. This not only maintains lubrication quality but also extends bearing life.

5. Automated Lubrication Systems

Oil circulation or metered grease systems deliver consistent lubrication based on time, load, or movement. These systems are particularly useful in high-throughput automation lines or CNC environments.

Conclusion

Choosing the right lubricant for linear bearings ensures smoother operation, longer lifespan, and reduced maintenance costs—critical to system reliability.For further questions please contact [email protected]